Table of Contents

Introduction

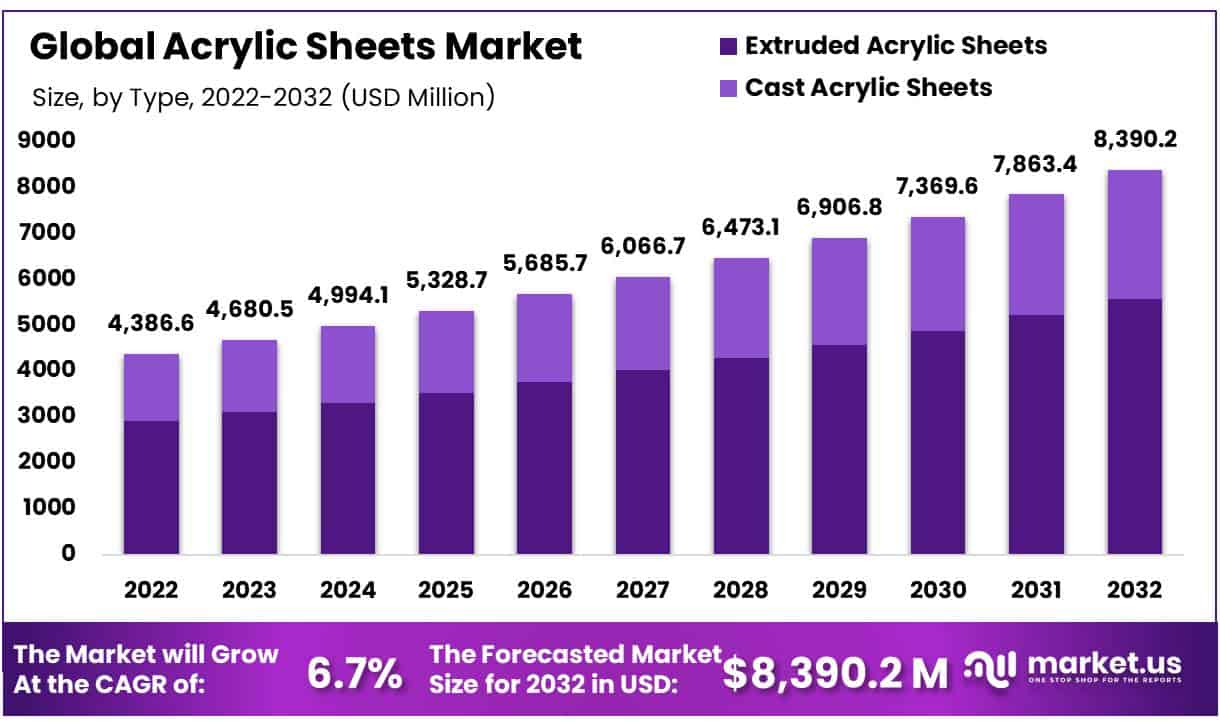

The global acrylic sheets market is poised for significant growth, expected to expand from USD 4,386.6 Million in 2022 to approximately USD 8,390.2 Million by 2032. This growth, representing a CAGR of 6.7%, is driven by several key factors and recent developments.

Acrylic sheets, known for their versatility and durability, are used across various industries. In the construction sector, they are valued for their light transmission properties, making them ideal for features like windows and skylights. The demand in this sector is a primary growth driver, especially with the increasing urban development and infrastructural investments globally.

The market faces challenges, particularly in the volatility of raw material prices, which can affect production costs and market stability. Moreover, the competition from alternative materials like polycarbonate and glass poses a substantial challenge, as these materials sometimes offer cost or performance advantages over acrylic sheets in specific applications.

Recent developments in the market include innovations aimed at expanding the functionality of acrylic sheets. These include UV and impact resistance enhancements, making acrylic sheets more suitable for demanding applications in the automotive and aerospace sectors, where durability and performance are crucial.

Mitsubishi Chemical Holdings Corp. is deeply integrated across various segments, focusing on high-performance materials, including acrylic products. Mitsubishi Chemical’s commitment to sustainability and innovation makes it a significant player in the acrylic sheets market. Their approach involves leveraging advanced technologies and sustainable practices to meet the growing demands of various industries. Evonik Industries AG continues to enhance its offerings in the specialty chemicals sector, including acrylic sheets. Evonik is known for its dedication to producing high-quality materials that support a range of industrial applications, from automotive to construction, emphasizing sustainability and innovation in their product development.

Overall, the acrylic sheets market is set to capitalize on the expanding applications in both traditional sectors like construction and emerging sectors like healthcare, where they are used for sanitary applications and barriers, further driven by the needs highlighted during the COVID-19 pandemic

Key Takeaways

- The global Acrylic Sheets market is valued at USD 4,386.6 Million in 2022.

- By Type, the Cast Acrylic Sheets segment dominated the market with a market share of 4% in 2022.

- By Product Type, the UV-resistant Acrylic Sheets segment dominated the market with a major market share in 2022.

- The Applications, Construction, and architecture segment led the market in 2022 with a market share of 35.4%.

- In 2022, the APAC region will be the dominant region in the global Acrylic Sheets market, with a market share of 34.2% of global revenue.

Acrylic Sheets Statistics

- It can transmit up to 92% of visible light and is perfect for outdoor applications: all plates contain a UV absorber to ensure that colors last over time.

- By allowing up to 90% of solar energy and 88% of visible light through.

- Plants need around 70-75% of light to grow optimally and acrylic sheets offer light transmission up to 92%.

- Acrylic sheets have an impact resistance 6-7 times greater than that of glass

- Up to 17 times the impact resistance of ordinary glass

- Laser cutting on 3mm acrylic tends to “burn” 0.2mm across the cutting line.

- The details should not be smaller than 1mm, because they would become too fragile.

- The acrylic sheets have a tolerance of +/- 10% compared to the nominal thickness.

- Under normal atmospheric conditions, an acrylic sheet contains about 0.5% water

- Stand the Acrystar sheet on the rack with the bottom inclined at a 10-degree angle.

- It is recommended to keep the total thickness of a cluster of sheets within 30 cm.

- Acrystar sheet with an ignition temperature of 400ºC is not highly flammable, but the sheet will be burned when exposed to naked fire.

Emerging Trends

The acrylic sheets market is experiencing several emerging trends that are shaping its future. One significant trend is the increasing application of acrylic sheets in the automotive sector. This growth is driven by the material’s versatility, light weight, and aesthetic appeal, making it ideal for various automotive parts like light covers and windshields.

Another prominent trend is the rising demand for acrylic sheets in construction and architectural applications. Their use in building facades, interior design, and architectural projects is expanding due to their excellent light transmission, UV resistance, and durability. This is further supported by the ongoing growth in the real estate sector.

In addition to these applications, there’s a growing preference for customizable acrylic sheets, which cater to diverse design needs in furniture and interiors, offering options in various thicknesses and colors. The acrylic sheets market is also benefiting from technological advancements that enhance product features such as UV resistance and impact resistance, making them more suitable for demanding industrial applications.

Overall, these trends indicate a robust expansion of the acrylic sheets market across multiple sectors, driven by both technological advancements and evolving industry requirements.

Use Cases

- Signage and Displays: Acrylic is widely used in the signage industry due to its clarity and durability. It’s ideal for both indoor and outdoor signs, including illuminated signs which are visible in various lighting conditions. This makes it a popular choice for business signage, advertising boards, and directional signs.

- Building and Architectural Applications: In construction, acrylic sheets are used for windows, skylights, and interior partitions. They offer a lightweight alternative to glass while providing excellent optical clarity and thermal insulation. This application is particularly valued in design projects where reducing weight while maintaining safety and energy efficiency is crucial.

- Protective Barriers: With the recent health crises, acrylic sheets have been extensively used as protective barriers in public spaces like banks, stores, and restaurants. These barriers are transparent, which helps maintain visual communication and prevents the spread of germs.

- Furniture and Interior Design: Acrylic’s aesthetic appeal and durability make it suitable for furniture like tables and decorative panels. It’s also used in interior design projects to create unique, modern looks for residential and commercial spaces.

- Automotive and Transport: Acrylic sheets are utilized in the automotive industry for components such as light covers, windshields, and other parts where high impact resistance and lightweight properties are beneficial.

- Medical Applications: In healthcare, acrylic is used for sanitary applications and equipment facades, providing safety and ease of cleaning.

Key Players Analysis

Mitsubishi Chemical Holdings Corp. is a significant player in the acrylic sheets market, known for its SHINKOLITE™ brand of acrylic sheets. These sheets are highly valued for their exceptional weather resistance, processability, and aesthetic qualities. Mitsubishi’s SHINKOLITE™ range includes various specialized products like flame-retardant and impact-resistant grades, catering to a diverse array of applications such as signage, displays, and construction projects. Their continuous innovation and commitment to environmental sustainability make them a standout in the acrylic market.

Evonik Industries AG is another key contributor to the acrylic sheets sector, particularly renowned for their PLEXIGLAS® brand. Evonik’s acrylic sheets are utilized across various industries, including automotive, construction, and electronics, due to their durability, light transmission properties, and versatility. Evonik focuses on developing application-specific acrylic solutions, enhancing product functionality to meet the unique demands of each market segment they serve. Their ongoing research and development in acrylic technology underline their role as a leader in the acrylic sheets market.

Arkema SA has made significant strides in the acrylic sheets sector through its subsidiary, Altuglas International. They have introduced a new range of acrylic sheets known as Altuglas Metallic & Iridescent, specially developed for Point of Purchase (P.O.P) displays, shop fittings, interior architecture, and furniture. This innovative product line offers sheets with unique aesthetic qualities such as metallic, sparkling, or iridescent effects that change depending on the viewing angle. These features make them particularly appealing for design-oriented applications, providing creative flexibility to designers and decorators.

Avient Corp is actively engaged in the acrylic sheets market, focusing on providing specialized and sustainable material solutions. Their approach is tailored to transform customer challenges into innovative products, making a significant impact across various industries. Avient emphasizes the development of application-specific acrylic solutions that are not only effective but also sustainable, aiming to address the evolving needs of the market. Their work in the acrylic sheets sector demonstrates a commitment to innovation and sustainability, aligning with broader industry trends towards environmentally friendly materials.

Trinseo SA has positioned itself prominently in the acrylic sheets market through its offerings of PLEXIGLAS® and ALTUGLAS™ polymethyl methacrylate (PMMA) cast sheets. These products are tailored to meet diverse design and manufacturing needs across multiple industries, including retail display, signage, aerospace, and architectural glazing. Trinseo’s focus is on delivering sheets that strike an optimal balance between performance and aesthetics, ensuring that each product meets the specific demands of its applications. This approach underscores Trinseo’s commitment to innovation and quality in the acrylic sheets sector.

Alro Steel Corporation, traditionally known for its role in metal distribution, also extends its services into the distribution of plastic materials, including acrylic sheets. Alro Steel provides a range of acrylic products that cater to various industrial and commercial needs. This includes providing materials for applications ranging from machine guards to retail displays, where acrylic’s clarity and durability are highly valued. Alro’s involvement in the plastics sector highlights its adaptability and commitment to meeting the diverse material needs of its customer base.

Lucite International is a key player in the acrylic sheets sector, recognized for its pioneering work in the production of MMA (methyl methacrylate) and PMMA (polymethyl methacrylate). A subsidiary of Mitsubishi Chemical Corporation, Lucite International emphasizes innovation in its acrylic products, catering to a wide range of applications such as automotive, medical, and electronics. Their approach includes developing high-quality, durable acrylic sheets that support sustainability through initiatives like recycling PMMA to achieve a circular economy in plastics.

Aristech Surfaces LLC specializes in continuous cast acrylic sheets, which are renowned for their high quality and performance in various applications including hot tubs, bath and shower enclosures, and outdoor kitchen surfaces. Aristech’s focus on innovative surface solutions is evident in their diverse product offerings that meet both functional and aesthetic needs, making them a prominent name in the industry for architectural and design applications.

Plaskolite has established itself as a leading manufacturer in the acrylic sheets industry, well-known for its diverse range of high-quality acrylic products under the OPTIX brand. Their offerings include standard acrylic sheets and specialized versions like the OPTIX-L Series, which are designed for specific applications such as display cases and signage due to their excellent clarity and high molecular weight. Plaskolite’s products are favored for their superior fabrication capabilities and versatility, making them suitable for a broad array of uses across various sectors, including architecture, signage, and safety and security applications.

A&C Plastics, Inc. is another prominent player in the acrylic sheets market, recognized for its extensive inventory and ability to meet specific customer needs with a wide variety of colors and thicknesses. Their focus is on providing tailored solutions that cater to diverse applications, from industrial uses to decorative purposes. A&C Plastics prides itself on delivering not just products but also expert advice and excellent customer service, ensuring that each client finds the perfect acrylic solution for their particular project.

Sumitomo Chemical is actively involved in the acrylic sheets sector through its Advanced Polymers Division, focusing on the production of PMMA (polymethyl methacrylate) products. Their acrylic sheets are renowned for their excellent optical clarity, durability, and resistance to weather conditions, making them suitable for a wide range of applications including automotive, construction, and electronics. Sumitomo Chemical’s dedication to innovation and quality assurance positions them as a key player in the global market for acrylic solutions.

Röhm GmbH is a leading provider in the acrylic sheets market, known for its PLEXIGLAS® and ACRYLITE® brands. Röhm specializes in high-quality PMMA products that cater to a diverse array of industries such as automotive, construction, and electronics. Their focus on sustainability and innovation is evident in their continuous development of acrylic products that offer superior performance and environmental benefits. Röhm’s commitment to quality and customer-centric solutions drives their success in the competitive acrylic sheets sector.

Schweiter Technologies AG has significantly expanded its footprint in the acrylic sheets market. Recently, Schweiter acquired the European acrylic sheet business and Perspex Distribution Ltd. from Lucite International UK Ltd. This strategic move, valued at £92 million, aims to bolster their product offerings and market reach in the acrylic sector. The acquisition not only enhances Schweiter’s capacity but also integrates about 220 employees from the acquired entities, underlining the company’s commitment to growth in the composites and acrylic market segments.

Unigel S.A. is a notable player in the acrylic sheets industry, primarily engaged in the production of specialty chemicals, including acrylic monomers which are critical for acrylic sheet manufacturing. Their activities in this sector underscore their focus on delivering high-quality products that serve various industries, including construction and advertising, where acrylic sheets are widely used for their durability and clarity. Unigel’s emphasis on integrating state-of-the-art technology and maintaining a robust supply chain ensures they remain competitive in the global market.

Conclusion

Acrylic sheets, known for their versatility and durability, are an indispensable material across various industries. Their wide range of applications—from signage and protective barriers to automotive parts and architectural elements—highlights their adaptability and the value they add to multiple sectors. The material’s clarity, strength, and lightweight nature make it a preferred choice over traditional materials like glass, especially in areas requiring safety and ease of maintenance.

As the market continues to evolve, driven by technological advancements and increased demand in sectors like healthcare and construction, acrylic sheets are set to play an even more pivotal role. The ongoing innovations and improvements in acrylic manufacturing are likely to enhance its applications and effectiveness, securing its place as a critical material in modern manufacturing and design.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)