Table of Contents

Introduction

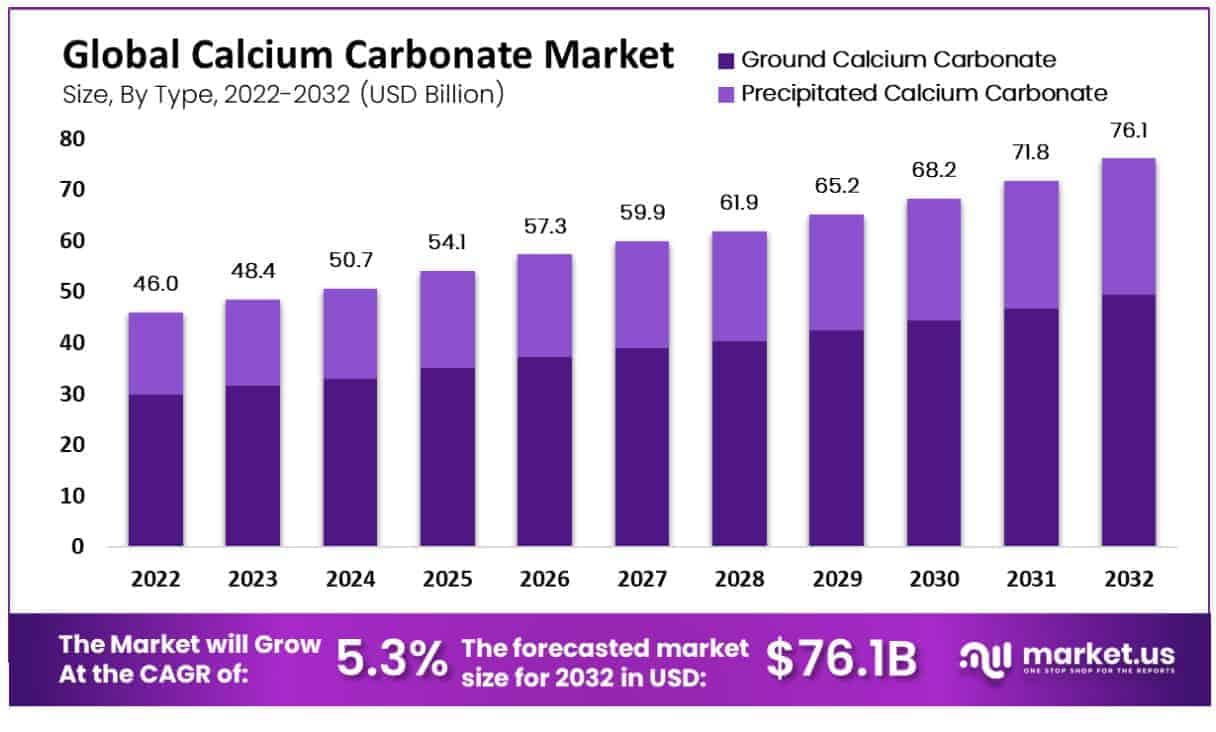

The global Calcium Carbonate Market is poised for substantial growth, with projections indicating an increase from USD 48.4 Billion in 2023 to approximately USD 76.1 Billion by 2032, reflecting a compound annual growth rate (CAGR) of 5.3% during the forecast period.

This expansion is primarily driven by the escalating demand across various end-use industries, including paper, plastics, paints and coatings, and construction. In the paper industry, calcium carbonate serves as a cost-effective filler and coating agent, enhancing brightness and opacity, thereby improving print quality.

The plastics sector utilizes it to enhance mechanical properties and reduce production costs, while the paints and coatings industry benefits from its ability to improve opacity and durability. Additionally, the construction industry’s growth, fueled by urbanization and infrastructure development, has increased the demand for calcium carbonate in cement and concrete applications.

The market’s popularity is further bolstered by its versatility and the continuous innovation in its applications. Emerging opportunities include the use of nano-sized calcium carbonate particles in pharmaceuticals and cosmetics, offering enhanced bioavailability and surface area. Furthermore, the rising emphasis on sustainable and eco-friendly products has led to increased adoption of calcium carbonate as a natural filler, aligning with global environmental initiatives.

The market’s expansion is also supported by technological advancements in production processes, improving efficiency and product quality. As industries continue to recognize the multifaceted benefits of calcium carbonate, its market trajectory remains positive, with sustained growth anticipated in the coming years.

Key Takeaways

- Calcium Carbonate Market Trends: It is anticipated that the calcium carbonate market will experience an average compound annual rate increase between 2023-2032 of approximately 5.3% CAGR.

- Analyzing Type: Analysis indicates a precipitated calcium carbonate (PCC) compound annual growth rate exceeding 4.2% over its predicted lifecycle.

- End-Use Industry: Celulosa, an Argentine firm, announced an increase of 30% in paper packaging production. Due to the increased food industry’s need for paper packaging products, Celulosa focused its efforts on this regard.

- Regional Analyses: By 2022, Asia Pacific held the greatest market share and contributed 33.4% of worldwide income.

Calcium Carbonate Statistics

- In the blood, 40% of calcium is bonded to albumin, 13% to an anion such as phosphate and lactate, and the remaining 47% is free, unbound, ionized calcium.

- 1000 mg calcium carbonate is equal to 400 mg elemental calcium.

- Calcium carbonate dosage is determined by the patient’s age and the ailment being treated. Dosage for adult heartburn ranges from 500 mg to 1000 mg, with a maximum of 7 grams per day.

- The recommended daily intake of calcium for people is 1 to 1.2 gm, and for postmenopausal women it is 1.2 gm, ideally from food sources.

- Calcium carbonate (500 mg to 4 g) can be taken orally once a day, split with meals.

- Calcium carbonate is used to prevent aspiration before to labor. By the end of the third trimester, up to 80% of pregnant women suffer from GERD.

- Dissolve Barium 10 ml of nitric acid diluted to 10 pp 100 (R) with 0.50 g of calcium carbonate.

- Getting the Test Solution Ready 10 g of calcium carbonate should be dissolved in 100 ml of diluted acetic acid 10 pp 100.

- A conductivity meter was used to assess the calcium hydroxide feed solution’s concentration, and CB0 was adjusted between 5 and 100 mol/m3.

- Rocks like chalk and limestone are formed by CaCO3, which constitutes up 4% of the earth’s crust.

- Limestone makes up around 10% of all sedimentary rocks and is mostly formed of the minerals calcite and aragonite, which are distinct crystal forms of CaCO3.

Emerging Trends

- Increased Demand in Paper and Packaging: The paper industry remains a significant consumer of calcium carbonate, utilizing it as a filler to enhance brightness and opacity. The growing demand for paper packaging, driven by environmental concerns over plastic waste, is further boosting calcium carbonate consumption.

- Expansion in Plastics and Rubber Industries: Calcium carbonate is increasingly used as a filler in plastics and rubber products, improving their mechanical properties and reducing production costs. This trend is particularly notable in the automotive sector, where it contributes to lighter and more durable components.

- Advancements in Nano-Technology: The development of nano-sized calcium carbonate particles is opening new applications in industries such as pharmaceuticals, cosmetics, and electronics. These nanoparticles offer enhanced properties, including improved bioavailability and surface area, making them valuable in specialized formulations.

- Growth in Construction and Infrastructure: Calcium carbonate is utilized in construction materials like cement and concrete, enhancing durability and workability. The global expansion of infrastructure projects is driving increased demand for calcium carbonate in this sector.

- Rising Use in Water Treatment: Calcium carbonate is employed in water treatment processes to neutralize acidic conditions and adjust pH levels. The growing need for clean water and wastewater treatment solutions is contributing to its increased use in this field.

- Environmental and Sustainability Initiatives: There is a growing emphasis on sustainable practices, leading to the use of calcium carbonate as a natural filler in various products to reduce reliance on synthetic materials. This trend aligns with global efforts to promote eco-friendly manufacturing processes.

Use Cases

- Paper Industry: Calcium carbonate is extensively used as a filler and coating agent in paper production, enhancing brightness, opacity, and printability. It is estimated that approximately 10–20% of the composition of printing and writing paper consists of calcium carbonate.

- Plastics and Rubber: In the plastics industry, calcium carbonate serves as a filler to improve mechanical properties and reduce production costs. For instance, unplasticized polyvinyl chloride (uPVC) drainpipes may contain around 15–20% calcium carbonate, while uPVC window profiles can have 5–15% loading.

- Paints and Coatings: Calcium carbonate is widely used as an extender in paints, particularly in matte emulsion paints, where typically 30% by weight of the paint is either chalk or marble.

- Construction Materials: Calcium carbonate is utilized in the construction industry as an ingredient in cement and as a limestone aggregate for road building. It also serves as a raw material for the preparation of builders’ lime by burning in a kiln.

- Pharmaceuticals: Calcium carbonate is commonly used medicinally as an inexpensive dietary calcium supplement and as a gastric antacid. It is available over-the-counter in products like Tums and Rolaids.

- Agriculture: Agricultural lime, powdered chalk or limestone, is used as a method of neutralizing acidic soil, making it suitable for planting.

- Water Treatment: pH Regulation: Calcium carbonate is employed in water treatment processes to neutralize acidic conditions and adjust pH levels, aiding in the mitigation of acid rain effects in river ecosystems.

Major Challenges

- Environmental Concerns in Mining: The extraction of calcium carbonate through mining can lead to environmental degradation, including habitat destruction and pollution. Sustainable mining practices are essential to mitigate these impacts.

- Regulatory Compliance: Stricter environmental regulations require companies to invest in cleaner technologies and waste management systems, increasing operational costs.

- Supply Chain Instability: Global supply chain disruptions, such as those caused by the COVID-19 pandemic, have affected the availability and cost of raw materials, impacting production and distribution.

- Fluctuating Raw Material Prices: Variations in the cost of limestone, the primary source of calcium carbonate, can affect profitability and pricing strategies.

- Competition from Substitutes: Alternative materials like kaolin and precipitated calcium carbonate are gaining popularity, posing competition and potentially reducing market share for traditional calcium carbonate products.

- Transportation Challenges: High transportation costs and logistical complexities can affect the timely delivery of products, especially in regions with underdeveloped infrastructure.

- Market Saturation in Developed Regions: Mature markets in North America and Western Europe are growing at a slower rate, limiting expansion opportunities for calcium carbonate producers in these regions.

Market Growth Opportunities

- Expansion in the Paper Industry: Calcium carbonate is extensively used as a filler and coating agent in paper production, enhancing brightness and opacity. The global paper industry is projected to grow significantly, driving increased demand for calcium carbonate.

- Growth in Plastics and Rubber Applications: Incorporating calcium carbonate as a filler in plastics and rubber improves mechanical properties and reduces production costs. The expanding automotive and construction sectors are key drivers for this application.

- Advancements in Nano-Technology: The development of nano-sized calcium carbonate particles is opening new applications in pharmaceuticals, cosmetics, and electronics. These nanoparticles offer enhanced properties, including improved bioavailability and surface area, making them valuable in specialized formulations.

- Increased Use in Water Treatment: Calcium carbonate is employed in water treatment processes to neutralize acidic conditions and adjust pH levels. The growing need for clean water and wastewater treatment solutions is contributing to its increased use in this field.

- Rising Demand in Construction Materials: Calcium carbonate is utilized in construction materials like cement and concrete, enhancing durability and workability. The global expansion of infrastructure projects is driving increased demand for calcium carbonate in this sector.

- Environmental and Sustainability Initiatives: There is a growing emphasis on sustainable practices, leading to the use of calcium carbonate as a natural filler in various products to reduce reliance on synthetic materials. This trend aligns with global efforts to promote eco-friendly manufacturing processes.

- Growth in the Pharmaceutical Sector: Calcium carbonate is used medicinally as an inexpensive dietary calcium supplement and as a gastric antacid. The increasing prevalence of calcium deficiency and related health issues is driving demand in the pharmaceutical industry.

Key Players Analysis

AGSCO Corp. is a leading supplier of industrial minerals, including calcium carbonate, serving diverse industries such as agriculture, construction, and manufacturing. The company offers a wide range of products tailored to specific customer requirements, emphasizing quality and consistency. AGSCO’s commitment to customer satisfaction and its extensive distribution network have solidified its position in the market.

Carmeuse is a global manufacturer of lime, limestone, and mineral-based products, with a history dating back to 1860. The company operates numerous quarries and production facilities worldwide, supplying high-quality calcium carbonate to industries including steel, agriculture, and environmental management. Carmeuse’s dedication to innovation and sustainability has made it a key player in the calcium carbonate sector.

Blue Mountain Minerals specializes in the production of high-quality calcium carbonate products, serving industries such as agriculture, construction, and environmental management. The company focuses on providing consistent and reliable products, with an emphasis on customer service and technical support. Blue Mountain Minerals’ commitment to quality and innovation has established it as a trusted supplier in the market.

Carmeuse Lime & Stone Company, a subsidiary of Carmeuse, operates the world’s largest limestone quarry in Rogers City, Michigan. This facility produces high-calcium limestone and calcium carbonate products used in various applications, including steel production, construction, and environmental management. The company’s extensive operations and product offerings make it a significant contributor to the calcium carbonate industry.

GCCP Resources is a leading producer of high-quality calcium carbonate, with operations in Malaysia. The company focuses on the extraction and processing of calcium carbonate from its own quarries, ensuring a consistent supply of premium products. GCCP Resources serves industries such as paper, plastics, and construction, emphasizing sustainability and environmental responsibility in its operations.

GLC Minerals LLC is a producer of high-quality calcium carbonate products, serving industries including agriculture, construction, and environmental management. The company operates quarries and processing facilities, focusing on providing consistent and reliable products. GLC Minerals LLC’s commitment to quality and customer service has established it as a trusted supplier in the market.

Greer Limestone Company is a leading producer of limestone and calcium carbonate products, with operations in West Virginia. The company supplies a wide range of products for applications in construction, agriculture, and environmental management. Greer Limestone Company’s dedication to quality and customer satisfaction has made it a key player in the calcium carbonate sector.

Midwest Calcium Carbonates specializes in the production of high-quality calcium carbonate products, serving industries such as agriculture, construction, and environmental management. The company focuses on providing consistent and reliable products, with an emphasis on customer service and technical support. Midwest Calcium Carbonates’ commitment to quality and innovation has established it as a trusted supplier in the market.

ILC Resources is a leading supplier of industrial minerals, including calcium carbonate, serving diverse industries such as agriculture, construction, and manufacturing. The company offers a wide range of products tailored to specific customer requirements, emphasizing quality and consistency. ILC Resources’ commitment to customer satisfaction and its extensive distribution network have solidified its position in the market.

Imerys is a French multinational company specializing in the production and processing of industrial minerals, including calcium carbonate. The company operates globally, supplying high-quality products to industries such as paper, plastics, and construction. Imerys’ dedication to innovation and sustainability has made it a key player in the calcium carbonate sector.

J.M. Huber Corporation is a diversified company with operations in various industries, including the production of calcium carbonate. The company focuses on providing high-quality products and services to its customers, emphasizing innovation and sustainability. J.M. Huber Corporation’s commitment to excellence has established it as a trusted supplier in the market.

LafargeHolcim, now known as Holcim Group, is a Swiss multinational company that manufactures building materials, including calcium carbonate products. The company operates in around 60 countries, supplying materials for construction and infrastructure projects. Holcim’s dedication to innovation and sustainability has made it a key player in the calcium carbonate sector.

Conclusion

In conclusion, Calcium Carbonate Stands as a pivotal compound with extensive applications across various industries, including paper, plastics, construction, and pharmaceuticals. The global market for calcium carbonate is projected to experience significant growth, with estimates indicating an increase from USD 48.4 Billion in 2023 to approximately USD 76.1 Billion by 2032, reflecting a compound annual growth rate (CAGR) of 5.3% during the forecast period.

This expansion is primarily driven by the escalating demand across various end-use industries, including paper, plastics, paints and coatings, and construction. In the paper industry, calcium carbonate serves as a cost-effective filler and coating agent, enhancing brightness and opacity, thereby improving print quality. The plastics sector utilizes it to enhance mechanical properties and reduce production costs, while the paints and coatings industry benefits from its ability to improve opacity and durability.

Additionally, the construction industry’s growth, fueled by urbanization and infrastructure development, has increased the demand for calcium carbonate in cement and concrete applications. The market’s popularity is further bolstered by its versatility and the continuous innovation in its applications. Emerging opportunities include the use of nano-sized calcium carbonate particles in pharmaceuticals and cosmetics, offering enhanced bioavailability and surface area.