Table of Contents

Introduction

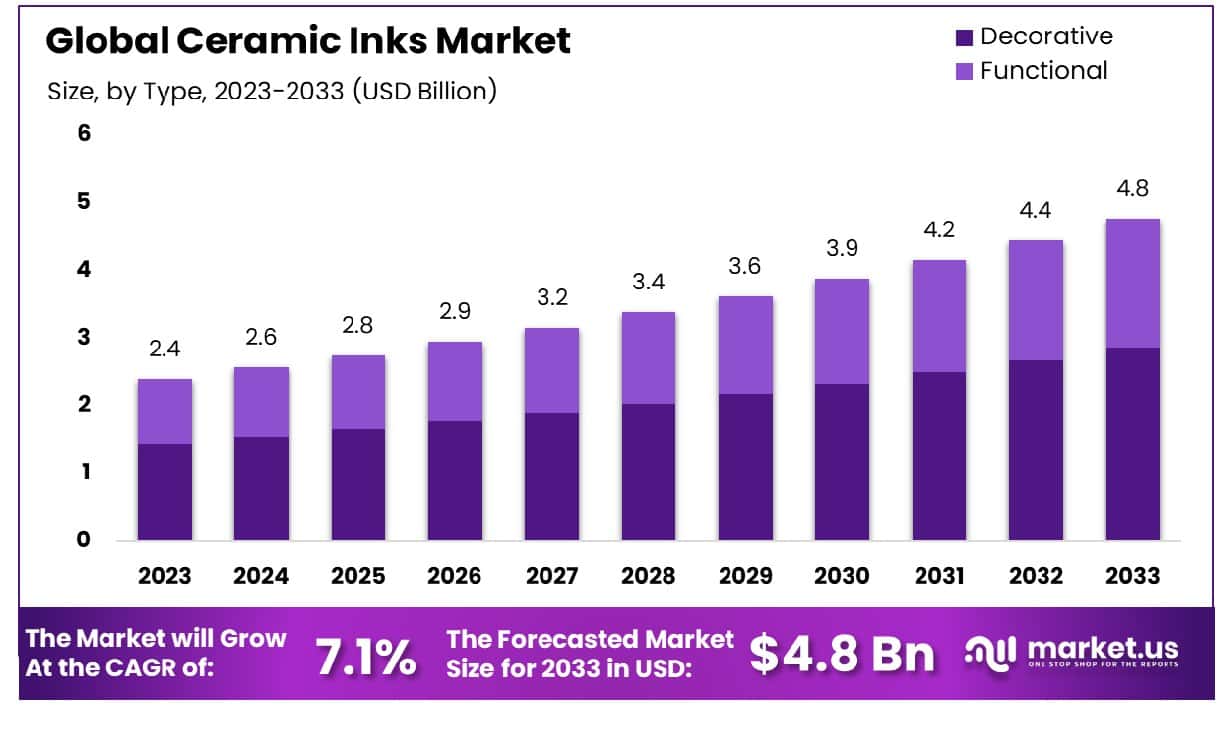

The Global Ceramic Inks Market is projected to experience significant growth, expanding from USD 2.4 billion in 2023 to an estimated USD 4.8 billion by 2033, demonstrating a robust Compound Annual Growth Rate (CAGR) of 7.1% over the forecast period from 2024 to 2033. This market expansion can be attributed to several key factors, including advancements in digital printing technologies and the rising demand for decorated ceramic tiles in the construction industry.

However, the market faces challenges such as stringent environmental regulations regarding ceramic inks and the volatility of raw material prices, which could impede growth. Recent developments in the industry, such as innovations in ink formulations that comply with environmental standards, are expected to offer new opportunities and bolster market growth. Adopting eco-friendly inks and integrating new technologies in manufacturing processes are pivotal trends that align with global sustainability goals and consumer preferences, further fueling the market’s expansion.

Ferro Corporation has been at the forefront of innovation by launching a new series of sustainable ceramic inks designed to reduce environmental impact while maintaining high-quality print results. This initiative aligns with global sustainability trends and positions Ferro Corporation as a leader in eco-friendly production practices within the industry.

FRITTA has strengthened its market position through strategic partnerships aimed at enhancing its distribution networks across Europe and Asia. These partnerships have facilitated the entry of FRITTA’s high-performance ceramic inks into new markets, expanding their global footprint and customer base.

Colorobbia Italia SpA recently announced a significant investment in the expansion of its production facilities. This expansion, aimed at increasing the company’s production capacity by 30%, reflects Colorobbia’s commitment to meeting the growing demand for ceramic inks, particularly in emerging markets.

Kao Chimigraf has entered into a strategic merger with a leading digital printing company, aiming to combine expertise and resources to innovate in the digital ceramic printing space. This merger is expected to enhance Kao Chimigraf’s product offerings and improve its competitive edge in the market.

Esmalglass-Itaca Grupo has received substantial funding for research and development, focusing on the next generation of ceramic inks that are not only more efficient but also cater to the increasing consumer demand for customization and digitalization in ceramic tile designs.

Key Takeaways

- Market Growth: The Global Ceramic Inks Market size is expected to be worth around USD 4.8 Billion by 2033, From USD 2.4 Billion by 2023, growing at a CAGR of 7.1% during the forecast period from 2024 to 2033

- Asia Pacific dominates the Ceramic Inks Market with a share of 39.5%, totaling USD 0.9 billion.

- By Type: Decorative ink dominates with a 60.0% market share.

- By Formulation: Solvent-based inks lead at 47.5% formulation preference.

- By Technology: Digital printing technology captures 60.4% of the market.

- By Application: Ceramic tiles application holds a substantial 47.3% market share.

Ceramic Ink Composition and Properties

- In contrast, our Ecolor Ink only starts evaporating at a temperature between 200 and 250 degrees Celsius, reached only within the production machinery (kiln).

- Ecolor Ink is environmentally friendly as it contains odorless components that significantly reduce harmful emissions: 60% less FORMALDEHYDE, 50% less ALDEHYDE, 50% less VOCs (volatile organic compounds), and 20% less COT (total organic carbon).

The gelling point ranges between 1807 and 3343 Pa. Ink with 73% of 3Y-ZrO2 feedstock content was the most suitable for printing. - Although the sintered density of the SLS parts was only 32%, this could be increased to 54% by pressure infiltration (PI) with a ceramic powder suspension. Warm isostatic pressing of the composite SLS parts allowed increasing the green density to 90% and the sintered ceramic density to 92% TD.

- The inks consist of glass frits (glass powder), pigments, metal oxides, and organic solvents. The latter already evaporates during pre-drying at around 200° C. The remaining materials then irreversibly amalgamate with the carrier glass at over 650° C.

- The color specification shows that despite a decrease in color characteristics of the ceramic pigment during the manufacturing process of the toner, after application and baking at a temperature of 1000 °C, the color is converted to a suitable yellow intensity range.

Ceramic Ink Market and Application

- Antalis’ Xavier Jouvet explained that the Sign and Display market uses approximately 6.6 billion square meters of printed media of which 40% is printed digitally.

- It is estimated that the interior decoration market uses 23 billion square meters, of which only 17% is currently produced with digital imaging technologies per annum.

- The solid content of the pigment keeps the constant of 30 wt% and the GG concentration is in the range of 1% and 3% by weight of the dry pigment.

- The water-based ink has a similar rheological behavior to that of the GG solution when the guar concentration is less than 2.0% even if the solid content is 30 wt%.

- Ceramic inks typically contain 30-60% solid content, including pigments and glass frits.

Glass frits in ceramic inks are usually in the range of 5-30% by weight.

Rheological Properties of Ceramic Inks

- Pigment particle sizes in ceramic inks are typically 0.5-5 μm, with a d50 around 1 μm.

Dispersants are added to ceramic inks at 0.5-2% by weight of the pigment to improve stability. - Guar gum (GG) is commonly used as a rheology modifier in ceramic inks at 1-3% by weight of the pigment.

- Ceramic inks exhibit shear-thinning behavior, with a yield stress (τ0) of 7-20 Pa and a consistency index (K) of 0.04-2 Pa·s.

- The Windhab model can be used to fit the rheological data of ceramic inks, with R2 values typically above 0.98.

- The surface tension of ceramic inks is usually between 30 and 40 mN/m.

Emerging Trends

- Digital Printing Technology: There is a notable shift towards digital printing technologies in the ceramic ink industry. This trend is driven by the need for higher precision and greater flexibility in tile designs. Digital printing allows for complex and detailed imagery to be applied more efficiently and with less waste compared to traditional methods, enhancing both production speed and design versatility.

- Eco-friendly Inks: In response to increasing environmental regulations and a growing consumer preference for sustainable products, the development of eco-friendly ceramic inks is rapidly gaining momentum. These inks are formulated to reduce volatile organic compounds (VOCs) emissions and are often water-based, which minimizes their environmental impact.

- Customization: As consumer preferences shift towards personalized and unique products, manufacturers are leveraging ceramic inks to offer bespoke tile designs. This trend is facilitated by advancements in digital printing, which allows for short-run production of customized designs without significant cost increases.

- Improved Durability and Functionality: Recent innovations in ceramic inks have focused on enhancing the functional properties of ceramic tiles. These include the development of inks that contribute to durability, slip resistance, and even antibacterial properties, making ceramic tiles suitable for a wider range of applications and environments.

- Integration with IoT: The integration of ceramic tiles with Internet of Things (IoT) technology is an emerging trend where tiles can incorporate sensors and connected features. This integration is supported by the advanced capabilities of ceramic inks to adhere to and function on technologically enhanced surfaces.

Use Cases

- Architectural Ceramics: Ceramic inks are extensively used in the architecture sector for printing designs on ceramic tiles used in flooring, wall coverings, and facade elements. This application benefits from the durability and aesthetic versatility of ceramic inks, allowing architects and designers to create unique, vibrant spaces. The global market for ceramic tiles is projected to reach approximately USD 120 billion by 2026, indicating a substantial demand for ceramic inks in architectural applications.

- Glass Printing: Ceramic inks are crucial in the automotive and architectural glass industries, where they are used to print on glass panels. This includes applications such as vehicle windows, glass doors, and decorative or functional elements in buildings. The durability of ceramic inks ensures that designs withstand environmental factors and mechanical stress.

- Tableware Decoration: The use of ceramic inks in tableware decoration is a traditional yet evolving application. Modern digital printing technologies have transformed this sector, allowing for more intricate and colorful designs on ceramic plates, cups, and other items. This sector is expected to grow, driven by the rising demand for customized and artisanal tableware products.

- Sanitary Ware: In the sanitary ware industry, ceramic inks are used to add decorative patterns and functional coatings to products such as sinks, toilets, and bathtubs. These inks enhance the aesthetic appeal and functionality of sanitary products, making them resistant to chemicals and scratches.

- Electronic Device Components: A niche but growing application of ceramic inks lies in the electronics industry, where they are used for printing electronic circuits and components on ceramic substrates. This application takes advantage of the high temperature and electrical insulation properties of ceramics, essential for electronic devices.

Major Challenges

- Regulatory Compliance: One of the most pressing challenges is adhering to stringent environmental regulations. The production and use of ceramic inks often involve solvents and other chemicals that can be harmful to the environment. Regulatory bodies across the globe are imposing stricter controls on the emission of volatile organic compounds (VOCs) and the disposal of chemical wastes. Compliance with these regulations increases the cost of production and necessitates ongoing investment in cleaner technologies.

- Raw Material Price Volatility: The cost and availability of raw materials such as pigments, solvents, and resins are subject to fluctuations due to geopolitical tensions, trade policies, and other economic factors. For instance, the price of titanium dioxide, a key pigment in many ceramic inks, has been known to fluctuate significantly, affecting the cost stability in the market.

- Technological Integration: Keeping pace with rapid advancements in digital printing technology poses a challenge. Companies must continuously invest in new technologies to improve the quality, efficiency, and environmental compatibility of their inks. This requires not only financial resources but also expertise in integrating these technologies into existing production lines.

- Market Competition: The Ceramic Inks Market is highly competitive, with numerous players operating globally. Emerging markets attract new entrants, intensifying competition and putting pressure on pricing and margins. Companies must differentiate their offerings and improve their value proposition to maintain and gain market share.

- Consumer Preferences: Changing consumer preferences can pose a challenge, as there is a growing demand for customized and unique tile designs. This requires manufacturers to offer a wide range of colors and effects, demanding more versatile ink formulations and printing technologies.

- Economic Downturns: The market is sensitive to economic cycles, especially in the construction and housing sectors, which are major consumers of ceramic-coated products. Economic downturns can lead to reduced spending on construction and renovation projects, directly affecting the demand for ceramic inks.

Market Growth Opportunities

- Expansion into Emerging Markets: Many regions, particularly in Asia-Pacific and the Middle East, are witnessing rapid urbanization and industrial growth, leading to increased demand for ceramic products. Countries like China, India, and Brazil offer substantial opportunities due to their expanding construction sectors. For instance, the Asia-Pacific region is expected to account for over 60% of the global construction market by 2025, presenting a lucrative opportunity for the adoption of ceramic inks in architectural applications.

- Innovations in Eco-Friendly Inks: There is a growing consumer and regulatory push towards environmentally sustainable products. Developing ceramic inks that are low in VOCs, use organic materials, or are entirely solvent-free can meet these demands. Such innovations not only comply with stringent environmental regulations but also cater to the growing market segment that prioritizes sustainability.

- Advancements in Printing Technology: The digital transformation of the ceramic inks sector is still underway, with new printing technologies offering higher quality and faster production capabilities. Investing in these technologies can help companies achieve greater efficiency and versatility in tile design, thus attracting a broader customer base.

- Customization and Personalization: There is a rising trend towards personalized and custom-designed tiles in both residential and commercial spaces. By leveraging digital printing technologies, companies can offer a vast array of designs and patterns that meet specific consumer preferences, thereby differentiating their products in a competitive market.

- Integration with Advanced Materials: Developing ceramic inks that are compatible with advanced materials offers another avenue for growth. For instance, incorporating functional additives that provide antimicrobial properties or enhanced durability can appeal to sectors like healthcare and public infrastructure, where hygiene and longevity are critical.

- Collaborations and Strategic Alliances: Forming partnerships with technology providers, local distributors, and other stakeholders in the supply chain can facilitate access to new markets, share risks, and pool resources for research and development. These collaborations can lead to innovative product developments and quicker market penetration.

Key Players Analysis

Colorobbia Italia SpA has cemented its position as a leading entity in the ceramic inks sector by specializing in the production and distribution of a range of raw materials and semi-finished products for the ceramics and glass industries. The company, with a legacy dating back to 1921, actively engages in sustainable practices and adheres to environmental regulations across its global operations, which span 18 countries and include 29 companies. Their innovations in digital ceramic inks and other ceramic materials showcase their commitment to environmental protection and technological advancement.

Kao Chimigraf, based in Spain, specializes in developing and producing inks and varnishes tailored for inkjet, flexographic, and rotogravure printing. The company leverages advanced technologies and a global distribution network to meet diverse industry needs, focusing particularly on inkjet inks that cater to various printing applications. This focus supports environmental sustainability efforts by enhancing printing efficiency and reducing waste.

Ferro Corporation, a key player in the ceramic inks sector, was acquired by Esmalglass-Itaca Group in 2020. This acquisition aimed to create a global leader in the ceramic glazes, inks, and colors sector, significantly enhancing their market presence and capabilities. Ferro has been pivotal in supplying high-quality ceramic inks used for various applications such as tiles and glass, supporting digital and analog printing technologies.

FRITTA is recognized for its innovative contributions to the ceramic inks sector, particularly for digital ceramic printing technologies. The company has developed a diverse range of ceramic inks and glazes tailored for digital applications, enabling high-quality, detailed decoration on ceramic tiles. Their products are designed to work with advanced piezoelectric DOD printheads, which support a wider color gamut and stronger color effects. This innovation enhances the functional and aesthetic qualities of ceramic products, meeting the evolving demands of the industry.

Esmalglass-Itaca Grupo is a leading company in the development and production of ceramic inks, frits, glazes, and colors for the ceramic industry. Known for its commitment to innovation and sustainability, the company has pioneered digital ink technologies that enhance the quality and design of ceramic products. Their recent advancements include water-based digital inks and glazes, which not only offer a rich color palette and detailed decoration possibilities but also contribute to environmental sustainability by reducing waste and water usage.

Zschimmer & Schwarz has established itself as a significant player in the ceramic inks sector, focusing on both solvent-based and water-based digital inks. Their expertise in organic chemistry and fluid dynamics helps them produce high-quality ceramic pigments that meet precise industry standards. The company emphasizes sustainability with its water-based inks, which reduce environmental impact while maintaining high quality and color intensity for ceramic decorations.

Torrecid Group is renowned for its significant innovations in the ceramic inks sector, particularly through its “INKCID” solution. This comprehensive digital decoration technology enhances ceramics, glass, and other materials by offering high-quality, unique, and value-added products. Torrecid has been pivotal in evolving digital printing for ceramics, promoting more effective, flexible, and sustainable production processes. Their wide array of digital inks ensures vibrant and precise color applications, meeting diverse industrial needs.

INKCID, developed by Torrecid Group, represents a cutting-edge global digital decoration solution for the ceramic and glass industries. It offers a diverse range of high-quality digital inks and enamels that facilitate the production of unique, high-value ceramic and glass products. INKCID enables manufacturers to achieve superior competitive advantages by enhancing product aesthetics and performance, making it a key driver in the modernization of digital ceramic printing.

Rex-Tone Industries Ltd, under its brand A.T. Inks, is a prominent player in the ceramic inks sector, particularly known for its comprehensive range of digital inkjet inks. The company offers innovative solutions tailored for various substrates, including ceramics. Rex-Tone has leveraged its extensive experience to develop specialized inks that cater to the detailed and high-quality demands of ceramic printing, supporting both wet-on-wet and other digital printing techniques. Their products are designed to enhance the color intensity and durability of ceramic prints, making them a key supplier in the digital ceramic printing industry.

Spicer S.P.A. has significantly influenced the ceramic inks sector with its comprehensive range of high-quality digital inks. The company specializes in the production of digital inks designed for detailed and high-resolution image reproduction on ceramic surfaces, accommodating the intense temperatures of the ceramic firing process. Their innovative approach includes the development of eco-friendly inks that reduce environmental impact without compromising on color quality or durability. This makes Sicer a key player in enhancing the aesthetic and functional qualities of ceramic products, thereby revolutionizing ceramic decoration and design.

Sun Chemical is a leading supplier in the ceramic inks sector, recognized for its advanced SUNIC Inkjet Inks. These inks are tailored for the ceramic industry, ensuring maximum stability and compatibility across various ceramic technologies like red paste and porcelain. Sun Chemical’s offerings are distinguished by their wide color range, specialized formulations, and the ability to produce vibrant, high-quality results on ceramic tiles. The company focuses on innovative, high-performance products that meet the rigorous demands of the industry, continuously driving advancements in digital ceramic printing.

TECGLASS specializes in producing a comprehensive range of ceramic inks tailored for digital printing on glass, focusing heavily on meeting the diverse needs of the architecture and design sectors. Their Jetver product line, including Jetver Ultra, is renowned for its vibrant colors and exceptional durability, making it ideal for both interior and exterior applications. TECGLASS inks are designed to achieve superior resistance to environmental conditions, abrasion, and UV radiation, ensuring longevity and aesthetic appeal of the glass decorations. This versatility is enhanced by their capability to customize colors to precise specifications, providing solutions for a wide array of design requirements.

Megacolor Ceramic Products, a Spanish company, specializes in the manufacture and distribution of ceramic colors and inks. The company is noted for its continuous innovation and research in the ceramic decoration sector, introducing a range of digital inks designed to create unique effects. Their inks are known for their excellent stability, quality, and environmental friendliness, which supports diverse ceramic printing technologies. This innovation allows Megacolor to offer unique solutions that meet the dynamic needs of their customers.

Guangdong Dowstone Technology Co., Ltd. is a prominent China-based company that specializes in developing and manufacturing a variety of inorganic non-metallic materials, including ceramic inks. They focus on offering a broad range of products designed for the ceramic sector, with an emphasis on innovative ceramic ink formulations that cater to different types of digital printing needs. The company combines its expertise in material science with robust research and development efforts to enhance product performance and meet the specific demands of its clients, emphasizing sustainability and quality across its product lines.

Belgium Glass and Ceramics (P) Ltd, established in 1993, is a leading manufacturer in the ceramic inks sector. The company excels in producing ceramic digital inks, including specialized inkjet inks, frits, and glazes, catering to the ceramic tiles industry. Their innovative R&D center and advanced manufacturing capabilities, including nano grinding mills, position them as a key player in the market.

Conclusion

The Ceramic Inks Market is poised for substantial growth, driven by advancements in digital printing technology, increasing demands from the construction and decoration industries, and a growing emphasis on sustainability. While the market faces challenges such as stringent environmental regulations and volatile raw material prices, the opportunities for expansion into emerging markets, innovations in eco-friendly products, and advancements in printing technology present significant potential for growth.

Companies that strategically navigate these opportunities and challenges, focusing on innovation and market expansion, are likely to achieve notable success in the coming years. As the market continues to evolve, staying ahead of technological trends and consumer preferences will be crucial for maintaining a competitive edge in this dynamic industry.