Table of Contents

Introduction

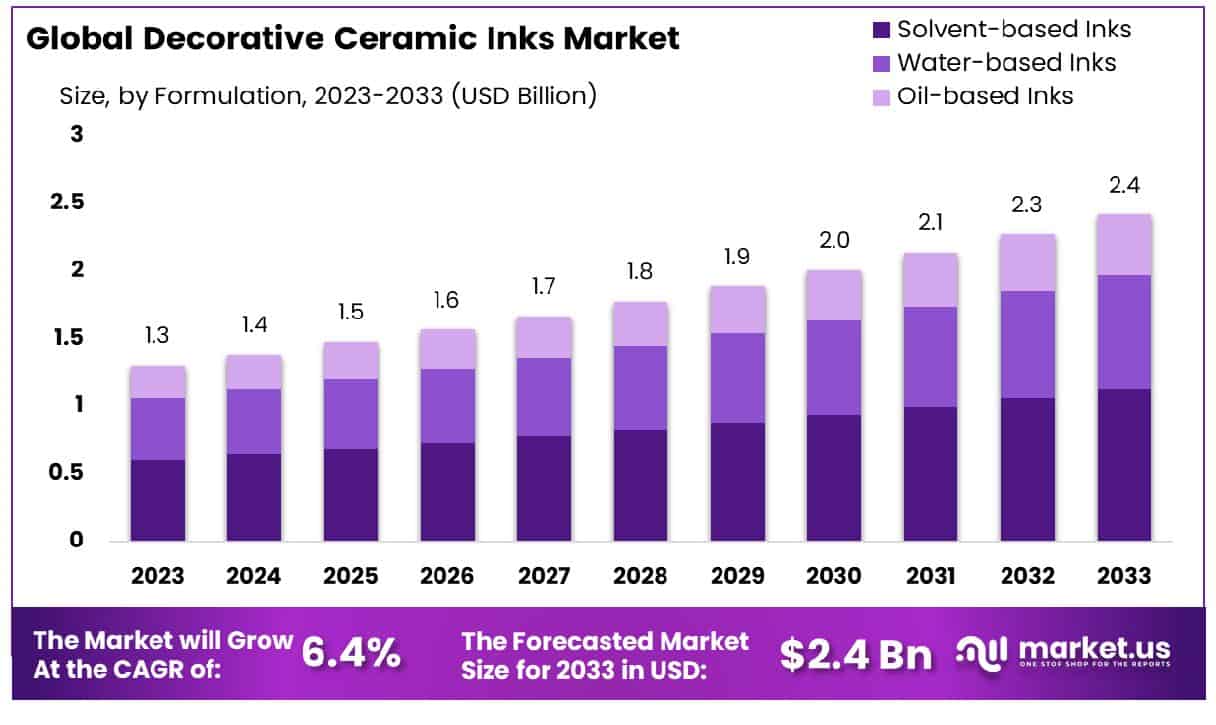

The Decorative Ceramic Inks Market is poised for notable expansion, with projections estimating the market to escalate from USD 1.3 billion in 2023 to around USD 2.4 billion by 2033, marking a steady Compound Annual Growth Rate (CAGR) of 6.4% from 2024 to 2033. This growth is primarily driven by the increasing demand for aesthetically enhanced ceramic tiles used in various construction and architectural projects. Moreover, technological advancements in inkjet printing technologies have broadened the application scope of ceramic inks, enhancing both the quality and variety of designs available, which in turn fuels the market’s expansion.

However, the market faces challenges such as stringent environmental regulations concerning the production processes and the volatility in raw material prices which could impede growth. Recent developments in the market include significant investments in R&D by key players aiming to develop eco-friendly inks and expand their product portfolio, catering to the rising consumer demand for sustainable and innovative products. These factors collectively underscore the dynamic nature of the Decorative Ceramic Inks Market, indicating a trend toward more sustainable practices and technological integration in the coming years.

Ferro Corporation, a leading provider in the market, recently expanded its digital printing solutions by launching a new line of eco-friendly ceramic inks in early 2023. These inks are designed to meet the growing demand for sustainable building materials, and they offer enhanced color vibrancy and durability. This innovation not only strengthens Ferro’s product portfolio but also positions it as a pioneer in sustainable printing solutions.

FRITTA has taken a significant step to enhance its global reach by acquiring a smaller competitor in July 2023. This acquisition enables FRITTA to leverage new manufacturing capabilities and broaden its distribution network, particularly in emerging markets where urbanization trends are driving the demand for decorated ceramics.

Colorobbia Italia SpA announced a partnership with a technology firm in May 2023 to co-develop advanced ceramic ink formulations. This collaboration aims to produce inks that can be cured at lower temperatures, thereby reducing energy consumption and emissions during the manufacturing process. This development is expected to cater to the evolving regulatory landscape pushing for more environmentally friendly production practices.

Kao Chimigraf successfully raised significant funding in late 2023 to support its research and development efforts focused on high-performance ceramic inks. This funding boost is intended to accelerate the development of inks that offer greater adhesion and color consistency, which are critical for high-end architectural and interior design applications.

Esmalglass-Itaca Grupo launched a new series of ceramic inks in 2024 that are specifically formulated for use in high-speed digital printers. This product launch responds to the industry’s shift towards faster production cycles and is designed to maintain quality at increased speeds, thereby improving efficiency for ceramic tile manufacturers.

Key Takeaways

- Market Growth: The Global Decorative Ceramic Inks Market size is expected to be worth around USD 2.4 Billion by 2033, From USD 1.3 Billion by 2023, growing at a CAGR of 6.4% during the forecast period from 2024 to 2033.

- In the Asia-Pacific region, the Decorative Ceramic Inks Market commands 38.4%, totaling US$ 500 million.

- By Formulation: Solvent-based inks dominate with a share of 46.5% in formulations.

- By Technology: Digital printing technology leads at 62.5% in the market.

- By Application: The ceramic tiles application segment holds a significant share of 42.6%.

Formulation and Preparation of Ceramic Inks

- The mean particle size (d50) of the vanadium-zircon blue pigment used in the ceramic ink experiment was 1 μm.

- The ceramic ink contained 85.71 g of pigment, 0.8571 g of dispersant, and 2 g of guar gum per 100 ml of deionized water.

- The ceramic ink was prepared by ball milling the pigment suspension and guar gum solution for 5 hours.

- Guar gum is a commonly used additive in ceramic inks, with concentrations ranging from 1% to 3% by weight of the dry pigment.

- The solid content of ceramic inks can vary from 30% to 50% by weight.

Performance and Application of Ceramic Inks

- For ceramic inks with 2.5% guar gum concentration, the yield stress (τ_0) ranged from 7.693 Pa at 1% solid content to 20.831 Pa at 3% solid content.

- The ceramic ink with 2.5% guar gum and 3% solid content had the highest apparent viscosity (η_a) of 2.004 Pa·s.

- The printed and sintered alumina ceramic lattice structures had an average overall porosity of 78.7%, with 64.7% being hierarchical porous alumina.

- Ceramic ink roller-coater printing can handle a maximum width of 3.2 meters.

- Rheological measurements of ceramic inks are typically conducted using a rheometer with a shear rate range of 0.5 to 500 s^-1.

Emerging Trends

- Digital Printing Technologies: The shift towards digital printing technology is one of the most significant trends in the decorative ceramic ink industry. Digital methods allow for more intricate and precise designs, which are increasingly favored in both residential and commercial settings. This technology also enables manufacturers to offer customized tile designs more efficiently.

- Eco-Friendly Inks: As environmental concerns become more pronounced, there is a growing trend towards the use of eco-friendly inks. These inks are formulated to reduce the environmental impact of production processes by minimizing volatile organic compound (VOC) emissions and requiring less energy for curing and drying.

- Enhanced Durability and Functionality: There is a rising demand for ceramic inks that not only offer aesthetic appeal but also enhanced functionality. Inks that provide additional attributes such as antimicrobial properties or improved wear resistance are becoming more popular, particularly in sectors like healthcare and hospitality.

- Bright and Vibrant Colors: With advances in ink formulation, there is an increasing capability to produce a wider range of vibrant and lasting colors. This trend is driven by consumer desire for unique and personalized interior design options.

- 3D Printing: The integration of 3D printing technology with ceramic inks is an exciting development. This combination allows for the creation of three-dimensional ceramic objects with complex shapes and detailed patterns, opening up new possibilities for custom decor and architectural elements.

Use Cases

- Residential and Commercial Flooring: Decorative ceramic inks are extensively used in the flooring industry. In 2023, approximately 55% of ceramic tiles manufactured globally were utilized in residential settings, with a significant portion decorated using ceramic inks. These inks provide durability and a wide range of aesthetic options, from realistic stone and wood imitations to intricate patterns, catering to diverse design preferences in both homes and commercial spaces.

- Wall Cladding and Facades: About 30% of the tiles produced are used for wall cladding, where ceramic inks play a crucial role in offering both protective and decorative finishes. The ability of these inks to withstand environmental factors makes them ideal for exterior facades, enhancing building aesthetics while providing long-lasting performance.

- Sanitaryware: Decorative ceramic inks are also important in the sanitaryware industry, where they are used to apply colorful, intricate designs on bathroom fixtures such as sinks, toilets, and bathtubs. This market segment has seen a steady growth of 4% annually, driven by the increasing demand for personalized and designer bathroom interiors.

- Kitchenware and Tableware: The use of ceramic inks in kitchenware and tableware has grown due to their ability to withstand high temperatures and frequent washing. Approximately 20% of ceramic inks are used in this segment to create durable and visually appealing dishes, cups, and other ceramic utensils.

- Architectural Glass: While not traditionally associated with ceramic tiles, decorative ceramic inks are increasingly being used on architectural glass. This application has grown by 10% over the past five years, as these inks can be used to create energy-efficient, colored, and patterned glass for windows, doors, and partitions, combining functionality with aesthetic enhancement.

Major Challenges

- Technological Integration: Integrating advanced technology remains a challenge, particularly for smaller manufacturers. Digital printing technology, which is pivotal for achieving high-quality and customized designs, requires significant capital. Roughly 30% of small to medium enterprises in this sector struggle with the financial aspect of acquiring and maintaining cutting-edge technology.

- Supply Chain Disruptions: Global supply chain issues pose a constant challenge, affecting the availability and cost of essential materials. Over the past year, supply chain disruptions have led to an average delay of 25% in production timelines, impacting the ability to meet customer demands on time.

- Quality Consistency: Maintaining consistency in quality across different batches of ceramic inks is a major challenge due to variations in raw material quality and production processes. This issue is particularly pronounced in regions with less controlled manufacturing standards, affecting about 40% of the output globally.

- Skilled Labor Shortage: There is a notable shortage of skilled labor in the industry, especially in the areas of machine operation and maintenance for high-tech digital printing equipment. This shortage affects approximately 35% of ceramic ink manufacturers, limiting their operational efficiency and innovation capacity.

- Regulatory Compliance: Beyond environmental regulations, manufacturers also face challenges in complying with international standards and certifications that are often required by overseas markets. This compliance is crucial for expanding into new regions but can be complex and resource-intensive, affecting around 30% of companies looking to export their products.

Market Growth Opportunities

- Environmental Regulations: Stricter environmental regulations are a substantial challenge for the industry. Approximately 60% of ceramic ink manufacturers are required to modify their production processes to comply with new environmental standards that aim to reduce volatile organic compound (VOC) emissions. Compliance with these regulations involves significant investment in new technologies and processes, increasing operational costs.

- Raw Material Volatility: The prices and availability of key raw materials such as pigments, solvents, and ceramic particles are highly volatile. In the last year alone, the industry saw a 15% increase in raw material costs, which can fluctuate based on global supply chain issues, geopolitical tensions, and economic instability. This volatility makes it difficult for manufacturers to maintain consistent pricing and profitability.

- Technological Adaptations: The rapid pace of technological change presents a challenge as companies must continually invest in new machinery and software to keep up with advancements, such as digital printing technologies. Approximately 40% of manufacturers reported the need for regular technology upgrades every 3 to 5 years to stay competitive, which requires substantial capital investment.

- Market Competition: Intense market competition is another challenge, particularly with the emergence of low-cost producers from regions with less stringent regulatory environments. These competitors often undercut prices, making it tough for established companies to maintain market share without compromising on quality.

- Consumer Preferences: Keeping pace with changing consumer preferences is crucial yet challenging. The trend towards personalized and custom-designed tiles requires manufacturers to offer a broader range of options more frequently, pushing the need for flexible and fast-adapting production lines. About 50% of ceramic ink producers find it challenging to adapt their product offerings swiftly in response to changing trends.

Key Players Analysis

Ferro Corporation is a key player in the decorative ceramic inks market, offering a variety of inks tailored for digital ceramic and glass printing. Their products are designed to work efficiently with the latest digital printing technologies, enhancing color intensity and durability in ceramic decorations.

FRITTA specializes in the production of digital ceramic inks, well-suited for the latest piezoelectric DOD printheads. Their inks are crafted using advanced milling processes to ensure high color intensity and optimal performance in digital printing applications.

Colorobbia Italia SpA, a renowned entity in the ceramics sector, specializes in the development and commercialization of decorative ceramic inks, among other materials. With a strong focus on innovation and quality, they provide enhanced digital decoration solutions including inks that offer excellent chromatic performance and stability, supporting the intricate design needs of modern ceramics.

Kao Chimigraf engages in the production of decorative ceramic inks, focusing on high-performance inks that cater to various printing technologies. This specialization supports the creation of detailed and vibrant ceramic designs, positioning them as a key player in the sector.

Esmalglass-Itaca Grupo stands out in the decorative ceramic ink market for its innovative digital ink solutions that offer enhanced color intensity and quality. Their latest HCR inkjet inks and complementary HCP glazes extend the chromatic range while improving uniformity across tones, crucial for high-grade ceramic printing. These advancements allow for significant reductions in ink usage without compromising on visual appeal, making them a cost-effective choice in ceramic decoration.

Zschimmer & Schwarz specializes in the development and manufacturing of digital printing inks suitable for various industrial applications, including ceramics. They focus on creating tailor-made, high-quality inks that enable precise decoration and finishing on diverse surfaces. Their commitment to environmental sustainability is evident in their product formulations, emphasizing reduced emissions and the efficient use of resources. The company’s extensive expertise in chemical formulations enhances the performance and appearance of printed materials across multiple sectors.

Torrecid Group has significantly influenced the decorative ceramic inks market with their innovative solutions like INKCID. These solutions leverage advanced production technologies to deliver highly competitive and aesthetically superior products across various sectors, including ceramics and glass. Torrecid’s continuous R&D efforts over two decades have ensured they remain at the forefront of digital decoration technology, consistently introducing high-quality inks and glazes that enhance the value of the final products.

INKCID offers a comprehensive digital decoration solution for the ceramics and glass industries, developed by Torrecid. This solution includes a diverse range of digital inks and enamels designed to produce high-value, distinctive products. INKCID’s inks and glazes are developed using advanced production techniques and rigorous quality control measures, ensuring top performance and compatibility with various printing systems.

Spicer S.P.A is deeply entrenched in the decorative ceramic inks sector, providing advanced digital inks and solutions tailored for ceramic and glass decoration. Their products are designed to meet high industry standards for color precision and durability, suitable for both flat and structured surfaces. Sicer’s offerings include innovative pigmented inks for direct printing on vitrified surfaces, demonstrating strong chemical and abrasion resistance, essential for maintaining vibrant colors and quality in high-temperature environments.

Rex-Tone Industries Ltd, operating under the brand name AT Inks, is recognized as a leading manufacturer of digital inks in India. The company is headquartered in Mumbai with extensive production and R&D facilities in Vadodara, Gujarat. Rex-Tone Industries specializes in a wide range of ink types including solvent-based, eco-solvent, UV-curable, and ceramic inks, showcasing their versatility across various printing substrates. Their ceramic inks are particularly noted for their application in floor tile printing, ensuring minimal pinholes and vibrant color consistency, making them a reliable choice in the decorative ceramic inks sector.

Sun Chemical is a key player in the decorative ceramic ink market, offering high-tech digital ink solutions tailored for the ceramic and tile industry. Their product line, SUNIC Inkjet Inks, is developed to meet rigorous industry standards, providing a wide range of colors and special effects with maximum stability across various ceramic technologies. This positions Sun Chemical strongly in a market that appreciates innovation in high-quality decorative applications.

Tecglass stands out in the decorative ceramic inks sector for its comprehensive range of JETVER ceramic inks, tailored for various applications including architectural and automotive glass. These inks are celebrated for their exceptional color brilliance, especially in shades of red, yellow, and orange, and are noted for their high resistance to climatic conditions, abrasion, and UV radiation. Tecglass’s inks are versatile, meeting the rigorous demands of both decorative and functional glass applications, ensuring adherence to the most advanced glass coatings technologies. The company’s commitment to innovation is reflected in its continuous development of new colors and effects to meet client-specific needs.

Megacolor Ceramic Products, a Spanish company specializing in ceramic colors and digital inks, is renowned for its innovation in the decorative ceramic inks sector. The company recently expanded its offerings with a new range of digital effects designed to enhance the aesthetic qualities of ceramic products. These effects include reactive, matte, glossy, opaque, and luster digital inks, which allow for a wide range of customization options for ceramics. Megacolor’s products are noted for their environmental friendliness and high quality, offering durability and stability across various printing technologies. Their ongoing commitment to research and development ensures they remain at the forefront of the ceramic decoration industry.

Guangdong Dow Technology Co., Ltd. is actively involved in the decorative ceramic inks sector, primarily focusing on the production of ceramic inks and other related materials. Their work includes the development of innovative ceramic inks that are used across various applications, reflecting their strong commitment to research and development in the field. This positions the company well within the growing market for decorative ceramic inks, particularly in regions like Asia Pacific, which is seeing rapid expansion due to increased construction activities and a rising demand for aesthetically appealing ceramic products.

Belgium Glass and Ceramics (P) Ltd specializes in the production and export of various ceramic and glass products, including frits and glazes. The company leverages advanced technology and a specialized team to ensure high-quality results in ceramic industries. They offer comprehensive design services equipped with the latest digital decoration technology, supporting the needs of the decorative ceramic inks sector.

Conclusion

The market for decorative ceramic inks is poised for continued growth, driven by the increasing demand for aesthetically appealing ceramic tiles across various sectors including construction and interior decoration. As industries and consumers increasingly seek customization and unique design solutions, the role of decorative ceramic inks becomes more significant.

Moreover, advancements in printing technology and innovations in ink formulations are expected to enhance the quality and durability of printed ceramics, further bolstering market expansion. Stakeholders in the ceramic industry should remain attentive to the evolving trends and technological advancements to capitalize on the emerging opportunities within this dynamic market.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)