Table of Contents

Introduction

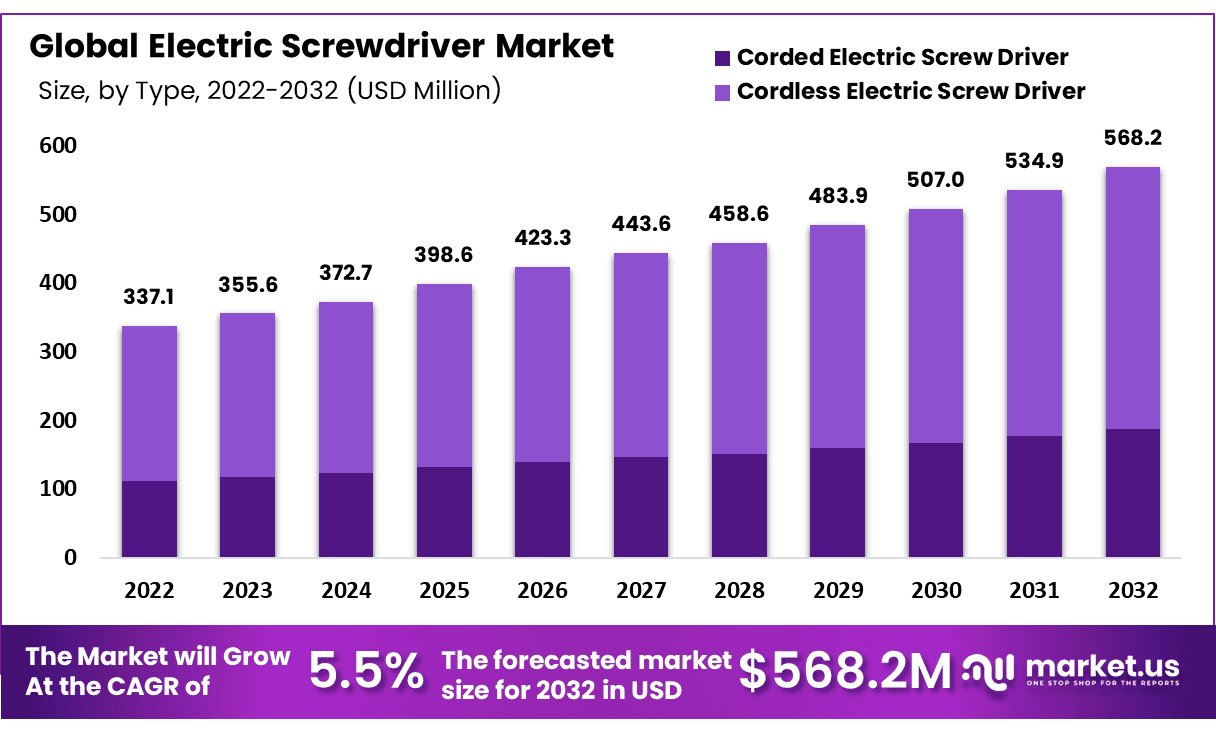

The global electric screwdriver market, valued at approximately USD 337.1 million in 2022, is projected to grow at a compound annual growth rate (CAGR) of 5.5% from 2023 to 2032, reaching around USD 568.2 million by the end of the forecast period. This growth is primarily driven by increasing demand for automation in various industries, as electric screwdrivers offer enhanced efficiency and precision in screwing operations. The market’s expansion is supported by significant advancements in cordless technologies, ergonomic designs, and integration with smart devices, making these tools more convenient and user-friendly for both professional and DIY use.

One of the key growth factors in this market is the rising adoption of electric screwdrivers in industrial applications, such as electronics, automotive, and manufacturing sectors, where efficiency and torque control are critical. The industrial segment remains the dominant application area, contributing significantly to market revenue. Cordless electric screwdrivers are especially gaining traction due to their portability and ease of use in tight spaces, further propelled by advancements in battery technology that extend operation time.

Recent developments in the market highlight efforts to overcome these challenges. For example, new product launches focus on enhancing battery life, improving torque control, and offering wireless connectivity for better operational feedback. The emergence of lightweight, compact designs has further increased the market appeal, particularly for applications requiring precision and mobility.

Robert Bosch Tool Corporation: In 2021, Bosch introduced the Bosch GO 2, an updated version of its popular electric screwdriver, which offers improved torque control and a compact, ergonomic design. It is aimed at both professionals and DIY enthusiasts.

Kolver Srl: In October 2018, Kolver launched the K-Ducer, an electric screwdriver with a built-in transducer, which is compatible with Industry 4.0 requirements. This innovation is aimed at improving precision and integrating smart manufacturing solutions.

Hitachi, Ltd. (now operating as Metabo HPT): In 2018, Hitachi Koki Co., Ltd. rebranded as Metabo HPT, signaling a renewed focus on high-performance tools. This change came with a push towards more compact, cordless electric screwdrivers, which are growing in demand due to their portability.

New Product Line: In March 2020, Makita U.S.A. launched the Impact XPS line of accessories, including bits for electric screwdrivers, designed to last 90 times longer than traditional bits, addressing durability and performance.

Product Launch: Makita also introduced the DF001DW 3.6V cordless screwdriver in 2020, which features a compact design for use in tight spaces, catering to professional users in the construction and automotive industries.

Electric Screwdriver Statistics

- The MDH3264-A right-angle electric screwdriver offers access to hard-to-reach fasteners in tight spaces. The drive on a right-angle tool is mounted at a 90-degree angle to the tool body.

- Lithium-Ion Battery: This rechargeable screwdriver comes with a lithium-ion battery, which offers extended runtime and holds a charge for up to 18 months.

- Customers have praised the convenience and precision of the 20V MAX* Lithium-Ion Drill/Driver, noting that the extended battery life and adjustable torque settings make it a versatile tool for various tasks.

- The new MINIMAT-ED is available in eight versions for torques between 0.24 to 18 Nm at speeds of 1500 rpm.

- Improve precision, efficiency, and quality control on assembly lines with the range of corded/battery-operated electric screwdrivers. Available in four different series and 12 models, these lightweight handheld tools offer accurate control in a torque range of 0.3 to 4.4 Nm and rotational speeds between 650 ~ and 1800 rpm.

- DID screwdrivers have an accuracy of ± 0.5% F.S., ±1 LSD.

- Powered by a rechargeable USB-C 3.6v battery, the E-Driver offers a cordless and convenient premium tool with up to 200 minutes of operating time per charge

- Crafted to C.K Tools trademark high standards, the E-Driver’s 6.35mm locking hex chuck retains the driver bit securely and its Torque adjustment dial, set up to 6Nm through the motor and up to 20Nm by manual rotation, allows for clear and easy adjustment to ensure screw fixings are tightened effectively.

- Cordless Battery Screwdriver with torque control for the insertion of BENEfit mini-implants. The iSD 900 will guarantee precise torque control due to the unique – easy to use – torque calibration system (10 – 40 Ncm).

- The screwdriver is delivered with bits (1/4” / 6,35 mm hex). You can quickly switch bits by pushing the chuck forward and attaching the bit.

- Operating time per charge is approximately 40 minutes and the charging time is around 60 minutes.

- The screwdriver can be charged in any USB port or with a regular 1A USB charger.

Emerging Trends

- Smart Features and Connectivity: Modern electric screwdrivers, especially cordless models, are now equipped with smart features. Tools can connect via Bluetooth to smartphones, allowing users to monitor battery life, adjust settings, and even track their tools through mobile apps. This integration enhances usability and efficiency, especially for professionals working in fast-paced environments.

- Ergonomic Design and User Comfort: Manufacturers are increasingly focusing on ergonomic designs to reduce user fatigue. Innovations include cushioned grips, balanced weight distribution, and compact, lightweight builds. These features are particularly useful for extended use in industrial settings, where tool control and user comfort are critical.

- Battery Technology: Advances in lithium-ion battery technology are improving the performance and convenience of cordless electric screwdrivers. These batteries offer longer run times, faster charging, and are more energy-efficient than traditional options. Some models also include smart charging systems that optimize battery life.

- Sustainability and Eco-Friendly Practices: Manufacturers are becoming more eco-conscious, incorporating sustainable materials and energy-efficient technologies. Recycled materials and energy-saving features, like automatic shut-off when the tool is not in use, are being integrated into newer models.

- Safety Innovations: Enhanced safety features, such as advanced locking mechanisms, automatic shut-off to prevent overheating and ergonomic designs that reduce the risk of injury, are becoming standard. These improvements make electric screwdrivers safer for both professionals and DIY enthusiasts.

Use Cases

- Home DIY Projects: Electric screwdrivers are widely used for assembling furniture such as bookshelves, cabinets, and beds. Their ability to provide precise torque control ensures that screws are neither too tight nor too loose, preventing damage to materials. Homeowners frequently use electric screwdrivers for tasks like hanging pictures, fixing loose screws on cabinets, or replacing door handles. Compact, cordless models make it easier to reach tight spaces.

- Construction Industry: Electric screwdrivers, especially models designed for drywall, make it easier to insert screws at the right depth without damaging the surface. Tools like Makita’s drywall screwdrivers are specifically built to handle this task with depth-adjustment features. In heavy-duty construction, high-torque electric screwdrivers are used to fasten large screws into wooden or metal frames, decks, and other structural components. Their precision and speed help reduce worker fatigue and increase productivity.

- Automotive Industry: In automotive manufacturing, electric screwdrivers play a crucial role in assembling various parts like engines, dashboards, and interior components. High-precision tools are necessary to ensure consistency and avoid damaging sensitive parts. Many manufacturers use smart screwdrivers with torque control to improve accuracy. Mechanics also use electric screwdrivers to perform repairs and maintenance, such as changing tires, replacing brake components, and assembling engine parts.

- Electronics Manufacturing: Electric screwdrivers with adjustable torque settings are essential for assembling delicate electronics, such as smartphones, laptops, and other gadgets. These tools prevent over-tightening, which can damage small components or printed circuit boards. In electronic device production, electric screwdrivers are often integrated into automated systems to ensure high-speed assembly with minimal errors. Tools with programmable settings allow manufacturers to adjust torque for different components without manual intervention.

- Furniture Manufacturing: Electric screwdrivers are used in mass production of furniture to fasten screws quickly and efficiently. Factories use cordless models with fast recharge capabilities to maintain a smooth assembly line process, minimizing downtime. In customized furniture production, electric screwdrivers are valued for their versatility, allowing workers to adjust torque and speed depending on the type of wood or material being used.

- DIY and Hobbyist Use: Hobbyists use electric screwdrivers for crafting projects that require light-duty fastening, such as building models, creating small wooden structures, or assembling 3D-printed parts. DIY enthusiasts often rely on electric screwdrivers for home improvement projects, from installing shelves and fixtures to creating custom cabinetry.

Major Challenges

- Battery Life and Recharge Time: Cordless electric screwdrivers, which rely on rechargeable batteries, face challenges in terms of battery longevity. Lithium-ion batteries, while efficient, still have limited capacity, especially in heavy-duty or extended-use situations. Users may experience frequent interruptions for recharging, particularly when working on large-scale projects.

- High Initial Costs: Electric screwdrivers, especially advanced models with smart features and high torque capabilities, tend to have higher upfront costs compared to manual tools. This can deter smaller businesses or DIY enthusiasts from investing in them, limiting the market’s growth in price-sensitive regions.

- Overheating During Prolonged Use: During intensive tasks such as construction or assembly line production, electric screwdrivers can overheat, affecting performance and durability. This problem is more prevalent in models without efficient heat dissipation mechanisms.

- Torque Accuracy: While electric screwdrivers offer adjustable torque settings, maintaining accuracy in sensitive applications like electronics manufacturing is challenging. Incorrect torque levels can lead to damaged components, leading to higher reject rates in production.

Durability of Cordless Models: Cordless models are often exposed to harsh environments, including dust, debris, and moisture. Despite advancements, these tools can wear out quickly in rugged conditions, making them less reliable over time compared to corded models.

Environmental Concerns: Disposal of batteries used in electric screwdrivers poses environmental risks. As these tools gain popularity, managing the end-of-life cycle of batteries, including proper recycling, is becoming increasingly important.

Market Growth Opportunities

- Rising Automation in Manufacturing: As industries adopt automated solutions to improve efficiency and precision, electric screwdrivers equipped with smart features such as Bluetooth connectivity and torque control are gaining popularity. These tools can streamline assembly processes, reduce human error, and increase productivity, especially in the automotive, electronics, and appliance manufacturing sectors.

- Growing DIY Market: The rising trend of DIY home improvement projects offers a significant opportunity for the electric screwdriver market. Cordless electric screwdrivers, which are user-friendly and versatile, are becoming essential tools for homeowners and hobbyists. The increased availability of affordable, battery-powered models has made these tools more accessible to non-professionals.

- Advancements in Battery Technology: Improved lithium-ion batteries are extending the runtime and reducing charging time for cordless screwdrivers, making them more reliable for continuous use. This advancement is particularly beneficial in construction and automotive applications, where frequent charging could disrupt workflow. Better battery performance allows these tools to be used in more demanding settings, thus expanding their market.

- Sustainability Initiatives: With a growing focus on eco-friendly practices, manufacturers are exploring ways to reduce the environmental impact of electric screwdrivers. Opportunities exist in developing recyclable components, energy-efficient motors, and battery recycling programs, which align with increasing consumer demand for sustainable products.

- Expansion into Emerging Markets: Regions like Asia-Pacific and Latin America, where industrialization and construction are booming, represent significant growth potential. As infrastructure projects increase, the demand for efficient electric screwdrivers in both professional and DIY markets is expected to rise.

Key Player Analysis

In 2023, Robert Bosch Tool Corporation significantly expanded its portfolio in the electric screwdriver sector by launching 32 new cordless tools, including advanced models for fastening and driving solutions. These tools, part of the 18V CORE battery platform, were introduced at the World of Concrete event in January 2023. The focus of Bosch’s development was to enhance user convenience with features like adjustable torque settings, ergonomic designs, and long-lasting batteries. Additionally, in June 2023, Bosch announced a $130 million expansion of its power tool accessories manufacturing site in Lincolnton, North Carolina, creating 400 new jobs to support its growing production.

In 2023, Kolver Srl made significant advancements in the electric screwdriver sector with the introduction of its K-Ducer NT series, a line of transducerized electric screwdrivers designed for high-precision applications. These screwdrivers, which range in torque from 5 to 70 cm, are built to meet the needs of industries requiring micro-torque control, such as electronics and medical device manufacturing. The K-Ducer NT is equipped with advanced control features like torque and angle monitoring, ensuring accurate and repeatable results for assembly operations.

Additionally, in early 2023, Kolver enhanced its offerings with updates to its control systems, integrating K-Link software, and allowing real-time data tracking from multiple devices, further aligning with Industry 4.0 standards. These developments showcase Kolver’s commitment to precision and innovation in the electric screwdriver market, making their products more intelligent and efficient for modern manufacturing processes.

In 2023, Hitachi Ltd., through its rebranded Metabo HPT (formerly Hitachi Power Tools), continued its focus on cordless electric screwdrivers, emphasizing advanced lithium-ion battery technology for extended runtime and higher efficiency. Their 18V cordless models are designed for precision tasks in industries like construction and automotive, offering features such as adjustable torque settings and ergonomic designs for ease of use. Additionally, in 2023, Hitachi’s innovation efforts included expanding their green and digital strategies, with developments in high-power tools that integrate smart features for better performance and connectivity.

In 2023, Makita Corporation continued to strengthen its presence in the electric screwdriver market through innovations in cordless technology. The company expanded its 18V LXT® series of cordless screwdrivers, focusing on offering longer battery life and enhanced torque control, making these tools ideal for both professionals and DIY users. In addition to the LXT line, Makita introduced new models under its 40V Max XGT® platform, specifically designed to meet the needs of heavy-duty applications with higher power output and faster charging times. These developments align with Makita’s ongoing commitment to sustainability and energy-efficient tools, helping to reduce reliance on corded and gas-powered equipment.

In 2023, Kilews Industrial Co., Ltd. continued its innovation in the electric screwdriver sector by expanding its portfolio of brushless and high-precision torque transducer screwdrivers. The company focused on developing smart tools for industrial applications, with a particular emphasis on improving torque accuracy and control. One of the highlights was the SGT-CS series, which offers torque ranges from 0.1 N.m to 25 N.m, making it ideal for delicate assembly tasks. In response to growing global demand, Kilews also reinforced its service centers in key regions like Korea, China, and the United States to provide better support for its expanding customer base.

In 2023, Harbor Freight Tools made significant strides in the electric screwdriver sector by expanding its HERCULES® professional line. In February, the company introduced new 20V brushless screwdrivers, including the Compact Impact Driver and Drill/Driver, aimed at professionals seeking durable, high-performance tools. These products feature advanced brushless motors, offering up to 80% more power and runtime compared to traditional models. Additionally, the tools come with enhanced features like variable speed control and ergonomic designs to reduce user fatigue, making them ideal for both heavy-duty and precision tasks.

In 2023, Mountz, Inc. continued to innovate in the electric screwdriver sector with the launch of the e-DRIV ECT-Series, a transducerized smart electric screwdriver system designed for high-precision torque control. This system enhances manufacturing efficiency by replacing up to 15 conventional tools with a single unit. The tool features real-time torque measurement, ensuring process reliability and reducing errors. Additionally, Mountz introduced advanced brushless electric screwdrivers, which offer reduced maintenance, improved energy efficiency, and extended lifespan, particularly suited for industries requiring strict torque accuracy.

Conclusion

In conclusion, the electric screwdriver market is poised for steady growth, driven by increased demand in industries like electronics, automotive, and construction, alongside rising DIY trends. Advancements in cordless technology, ergonomics, and battery life are making these tools more efficient and versatile. Additionally, the integration of smart features such as Bluetooth connectivity and torque control enhances their appeal for precision tasks. While challenges like high initial costs and battery limitations persist, continuous innovations are expected to address these issues. With expanding applications across various sectors and a growing emphasis on automation, the electric screwdriver market is expected to maintain a healthy trajectory in the coming years.