Table of Contents

Introduction

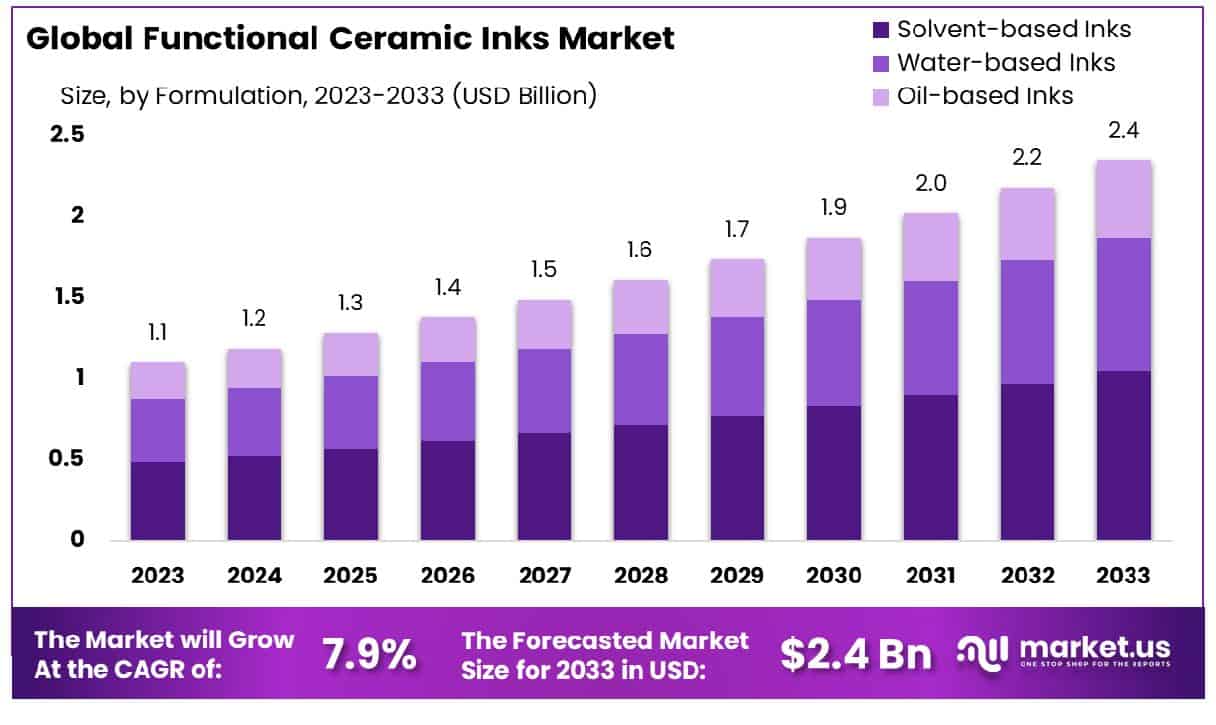

The Functional Ceramic Inks Market is anticipated to undergo substantial growth, with projections suggesting an increase from USD 1.1 billion in 2023 to around USD 2.4 billion by 2033, achieving a compound annual growth rate (CAGR) of 7.9% from 2024 to 2033. This market expansion can be attributed to several key factors, including advancements in digital printing technologies and increasing demand from the ceramic tile industry, which heavily relies on these inks for intricate design applications.

However, the market faces challenges such as the high cost of ceramic inks and stringent regulations concerning volatile organic compound (VOC) emissions during the manufacturing process. Recent developments have seen significant technological innovations aimed at reducing these environmental impacts, which are expected to further drive market growth. For instance, in 2022, a leading manufacturer introduced a new line of eco-friendly ceramic inks designed to lower VOC emissions by 30%, addressing both environmental and regulatory challenges effectively.

Ferro Corporation, a leading supplier in the market, launched an innovative series of ceramic inks in 2021 that are compatible with digital printing technology. This product line is specifically designed to enhance color vibrancy and print quality on ceramic substrates, aligning with the industry’s shift toward digitalization.

FRITTA has made significant strides by expanding its production capacity in 2022. The company invested an estimated USD 20 million to enhance its facilities in Spain, aiming to meet the growing global demand for high-quality ceramic inks, especially in emerging markets.

Colorobbia Italia SpA entered into a strategic partnership in 2023 with a prominent Asian ceramics manufacturer. This collaboration aims to develop and distribute advanced ceramic inks that are tailored for the architectural and automotive sectors, leveraging Colorobbia’s expertise in ceramic coatings.

Kao Chimigraf embarked on a merger in 2022 with a European digital ink company to pool resources and technology. This merger is expected to drive innovation in ink formulations, improve supply chain efficiencies, and expand their customer base in the European market.

Esmalglass-Itaca Grupo has focused on sustainability, launching a new line of eco-friendly ceramic inks in 2023. These inks are designed to reduce environmental impact by minimizing VOC emissions during the firing process, a critical advancement given the stringent environmental regulations in Europe and North America.

Key Takeaways

- Market Growth: The Global Functional Ceramic Inks Market size is expected to be worth around USD 2.4 Billion by 2033, From USD 1.1 Billion by 2023, growing at a CAGR of 7.9% during the forecast period from 2024 to 2033.

- In 2023, the Functional Ceramic Inks Market in Asia Pacific was valued at USD 423 million, representing 38.5% of the global market.

- By Formulation: Solvent-based inks dominate formulations, constituting 44.5% market share.

- By Technology: Digital printing leads in technology, commanding a 64.6% market share.

- By Application: Ceramic tiles top applications, representing 43.6% of market consumption.

Rheological and Structural Dynamics of Ceramic Inks

- Polyacrylate (NH4PAA) on the rheological properties of zirconia colloidal inks and prepared zirconia colloidal inks containing 47 vol.% zirconia and 0.8 wt% dispersant.

- The specimens were dried at room temperature for 24 hours. The dried specimens were debonded at 600 °C for 1 h firstly and then sintered at 1550 °C for 2 h with a heating rate of 3 °C min−1.

- Except for 52 vol.% slurries, the yield stress of other slurries exceeded 100 Pa and varied in the range of 164 Pa to 267 Pa.

- It is observed at a temperature of 1200°C that the water absorption of the functional composition is maintained at values of 30%, which will facilitate water exchange and internal diffusion in the process of humidity regulation.

- Although the strength of the ceramics was found to increase in the temperature range of 1300 – 1400°C, it decreases at 1500 – 1600°C due to the crystallization of the silica glass.

Innovative Applications and Enhancements in Ceramic Inks

- An estimated 100 million birds die each year in North America alone due to collisions with glass. Digital ceramic glass printing can help our winged friends stay safe while still achieving aesthetically pleasing scalable and colorful designs.

- In Spain, more than 2 million containers of inkjet ceramic inks are consumed in the ceramic decoration stage and are distributed in 5-kilo containers.

- A set of 800 binary ink mixtures and 100 single-ink mixtures were used to test the model and it was found that the best performance (median CIELAB E of 2.73 units) was possible using a high value of the Yule-Nielsen correction factor (n = 20).

- All ceramic composites are resistant to high operation temperatures, such as 120 ◦C or 525 ◦C, in the electronics packages.

- Although the sintered density of the SLS parts was only 32%, this could be increased to 54% by pressure infiltration (PI) with a ceramic powder suspension. Warm isostatic pressing of the composite SLS parts allowed increasing the green density to 90% and the sintered ceramic density to 92% TD.

Emerging Trends

- Digital Printing Technology: There’s a growing shift towards digital printing techniques in the ceramics industry. This technology allows for more precise and detailed designs, enabling manufacturers to offer customized and diverse patterns with faster production times. This trend is fueling the demand for functional ceramic inks compatible with digital printers.

- Sustainability Initiatives: Environmental concerns are pushing the development of eco-friendly ceramic inks. These inks are designed to emit fewer volatile organic compounds (VOCs) and consume less energy during the production process. Companies are investing in green technologies to comply with stringent environmental regulations and to appeal to a market increasingly driven by sustainability.

- Enhanced Ink Formulations: Advances in chemistry and materials science are leading to the creation of ceramic inks with improved properties, such as greater durability and better adhesion to ceramic surfaces. These innovations enhance the functionality and aesthetic appeal of finished ceramic products, expanding their applications in architecture and interior design.

- Expansion into New Markets: As the global economy grows, there is an increasing demand for ceramic products in emerging markets, particularly in Asia and Africa. This expansion is prompting companies in the ceramic inks industry to explore these new geographic areas, adapting their products to local tastes and manufacturing conditions.

Use Cases

- Ceramic Tiles: The primary use of functional ceramic inks is in the decoration of ceramic tiles. These inks enable high-resolution and complex designs, essential for modern interior design trends. The global ceramic tiles market, expected to reach USD 107 billion by 2023, relies heavily on these inks for aesthetic enhancements.

- Glass Printing: Functional ceramic inks are also crucial in the glass industry, particularly for printing on flat and automotive glass. This application includes creating durable and weather-resistant designs for windows, facades, and vehicle glass. The market for glass printing is projected to grow at a CAGR of 4.5% through 2025, partly driven by innovations in ceramic ink technology.

- Tableware Decoration: Another significant application is in the tableware sector, where these inks are used to apply decorative patterns and images on plates, cups, and other dinnerware. This market segment benefits from the ability of ceramic inks to withstand high temperatures and detergents, ensuring long-lasting designs.

- Electronics and Appliances: Ceramic inks find applications in the electronics industry, particularly for printing circuitry and decorative elements on household appliances. This use case is growing as manufacturers look to integrate more personalized and visually appealing designs into their products.

- Medical Devices: In the medical field, functional ceramic inks are used to mark instruments and devices for identification and functional purposes. These inks must adhere to strict medical standards, ensuring they can withstand sterilization processes without degradation.

Major Challenges

- High Production Costs: The production of high-quality functional ceramic inks involves significant costs, primarily due to the expensive raw materials and advanced technologies required. These costs are often passed on to the consumers, impacting the competitiveness of products, especially in price-sensitive markets.

- Technological Integration: Integrating new printing technologies with existing ceramic production lines can be complex and costly. This challenge is particularly acute for small to medium enterprises that may not have the financial flexibility to invest in the latest digital printing equipment.

- Regulatory Compliance: Functional ceramic inks are subject to stringent environmental regulations concerning the emission of volatile organic compounds (VOCs) and the use of heavy metals in pigments. Compliance with these regulations can be challenging and expensive, requiring ongoing investment in research and development to ensure products meet legal standards without compromising quality.

- Supply Chain Vulnerabilities: The global supply chain for the raw materials needed to produce ceramic inks is often volatile, with fluctuations in availability and price. This unpredictability can lead to production delays and increased costs, impacting overall market stability.

- Market Competition: The market is highly competitive, with numerous players offering similar products. Differentiating products in this crowded market requires innovation and significant marketing efforts, which can be daunting for smaller companies.

Market Growth Opportunities

- Expansion in Emerging Markets: With economic growth in regions like Asia Pacific and Latin America, there is a rising demand for ceramic products, particularly in construction and interior design. These regions offer a substantial growth opportunity for the ceramic inks market, projected to expand at CAGRs of 8.5% and 7.3% respectively from 2024 to 2033. Tapping into these markets with localized strategies and partnerships can yield significant returns.

- Innovations in Ink Technology: Developing new ink formulations that offer enhanced properties such as greater thermal stability, increased adhesion, and reduced environmental impact can meet the evolving demands of end-users. Innovations that lead to higher-quality prints and eco-friendly solutions can differentiate products in a competitive market.

- Adoption of Digital Printing Techniques: The shift towards digital printing in the ceramics industry is accelerating, driven by the need for more efficient and versatile production methods. By investing in digital printing technologies, companies can capitalize on the growing demand for customized and high-quality ceramic prints.

- Strategic Alliances and Mergers: Forming strategic alliances or merging with other companies can provide access to new technologies, markets, and expertise, enhancing competitiveness and market reach. These collaborations can also lead to improved R&D capabilities and supply chain efficiencies.

- Regulatory Compliance as a Market Strength: Companies that proactively comply with international environmental and safety regulations can use this compliance as a competitive advantage. Offering products that not only meet but exceed regulatory standards can attract customers looking for high-quality and sustainable solutions.

Key Players Analysis

Colorobbia Italia SpA specializes in producing advanced digital inks for the ceramic industry, including their environmentally-friendly AIR Evolution and eKo series. These innovations are focused on reducing emissions and enhancing production efficiency, thus aligning with increasing market demands for sustainable and high-quality ceramic products.

Kao Chimigraf is recognized as a key player in the functional ceramic inks market, focusing on delivering high-quality inks for various printing technologies, including digital and analog systems. The company specializes in inks that are crucial for applications in sectors like food and beverage packaging and pharmaceuticals. With rigorous testing and real-world applications, Kao Chimigraf ensures its products meet customer expectations in performance and value across regions such as Europe, Africa, and the Middle East.

Ferro Corporation is a prominent player in the functional ceramic inks sector, leveraging its expertise in ceramic and glass science to offer a wide array of digital printing inks. These inks are used across various applications including ceramic tiles and automotive glass, emphasizing durability and high-quality print performance.

FRITTA, a prominent player in the functional ceramic inks sector, continues to innovate with its advanced digital ceramic inks tailored for the latest piezoelectric DOD printheads. These inks, known for their superior color intensity and broader color gamut, are crafted using a high-energy milling process. This method not only enhances the ink’s physical properties like density and viscosity but also incorporates environmental considerations into its formulation. Additionally, FRITTA has launched new product ranges such as Surface inks and Digital Glaze, which are designed to create textured and volumetric effects on ceramic products, adding significant value to the digital printing process in ceramics.

Esmalglass-Itaca Grupo is a prominent provider in the functional ceramic inks sector, renowned for its innovative pigmented inks. Their recent advancements include HCR inkjet inks with enhanced color intensity and uniformity, which have been well-received for their ability to achieve vivid and consistent colors across a broad range of ceramic applications. This development has positioned them strongly within the market, especially noted for increasing the efficiency and reducing the consumption of inks in industrial processes.

Zschimmer & Schwarz is actively engaged in the production and development of digital inks for the ceramic industry, emphasizing solvent-based and water-based inks. These inks are designed to meet rigorous quality standards and are notable for their high color intensity and broad spectrum, making them suitable for various ceramic applications. The company places a strong emphasis on sustainability, particularly with their AQUACOLOR water-based inks, which reduce environmental impact while maintaining high printing quality.

Torrecid Group has made significant advancements in the functional ceramic inks sector with their patented InkCid technology, designed specifically for digital decoration. This innovation offers exceptional printing quality, allowing decoration up to the tile edges and facilitating rapid product changes with minimal waste, thereby enhancing production efficiency.

Rex-Tone Industries Ltd, operating under the brand name AT Inks, is a prominent manufacturer of digital inkjet inks in India, specializing in a range of inks for various substrates including ceramic tiles. The company offers comprehensive solutions for ceramic printing with products designed for high color intensity and minimal defects during the printing process. Their inks are tailored to meet the needs of various printing technologies and are known for their compatibility with multiple printhead technologies. Rex-Tone’s commitment to innovation is evident in their extensive R&D efforts and its ability to supply products globally, making them a significant player in the functional ceramic inks sector.

Sicer S.P.A is at the forefront of the digital ceramic inks sector, specializing in the production of eco-friendly inks and digital materials for ceramic decoration. Their products, designed for high-definition printing on ceramic surfaces, include a variety of inks that offer enhanced color gamut and stability under high temperatures. Sicer’s innovative ink series, such as the.LE Low Emission inks, are notable for their reduced environmental impact, emitting lower levels of harmful substances compared to conventional inks. This makes them a preferred choice for industries seeking sustainable solutions without compromising on quality or performance in ceramic manufacturing.

INKCID, developed by Torrecid, is a global solution in the digital decoration market for ceramics and glass. It offers a comprehensive range of digital inks and glazes designed to produce high-value, differentiated products with excellent printing quality up to the edges of ceramic tiles. The system enables the decoration of an unlimited number of tile designs without waste, due to its use of ready-to-use ink cartridges. Notably, INKCID has been patented and has found widespread adoption among major ceramic companies in Italy and Spain, demonstrating its effectiveness and market acceptance.

Sun Chemical stands out in the functional ceramic inks sector with its high-tech SUNIC Inkjet Inks, specifically designed to meet the rigorous demands of the ceramic industry. These inks offer a broad spectrum of colors and special effects, ensuring excellent compatibility with various ceramic technologies and enamels. Known for their outstanding color consistency and stability, Sun Chemical’s products cater to diverse ceramic printing needs, including various firing processes and ceramic bases.

TECGLASS specializes in ceramic inks for digital glass printing, offering a diverse range of colors and effects tailored to various applications like automotive, architecture, and home appliances. Their products are known for high resistance to climatic stressors, excellent durability of chromatic effects, and superior abrasion resistance in high-traffic areas. TECGLASS inks are designed to be compatible with advanced glass coatings, enhancing their versatility in both interior and exterior applications.

Megacolor Ceramic Products, a leader in the ceramic decoration sector, has expanded its product range to include a new line of digital effects inks. These innovative inks offer reactive, matte, glossy, opaque, and luster effects, enhancing the design and aesthetic qualities of ceramic surfaces. Recognized for their stability and eco-friendliness, these inks allow for versatile application across various printing technologies, solidifying Megacolor’s commitment to continuous innovation and support in the ceramics industry.

Guangdong Dowstone Technology Co., Ltd. is actively engaged in the ceramics industry, providing comprehensive product solutions including ceramic inks. The company caters to high-end ceramics manufacturers globally with a focus on digital ceramic solutions and enamel glazes, aiming to enhance the production capabilities of its clients.

Belgium Glass and Ceramics (P) Ltd specializes in supplying glass bottles and has expanded its offerings to include ceramic inkjet inks. The company is recognized for its expertise in the functional ceramic inks sector, providing products that cater to the ceramic and glass industries with a focus on quality and innovation.

Conclusion

The Functional Ceramic ink market is poised for significant growth, driven by the expanding use of digital printing technologies and the increasing demand from emerging markets. While the industry faces challenges such as high production costs and stringent environmental regulations, opportunities for innovation and strategic market expansion present pathways for substantial development.

Companies that invest in technology advancements, adhere to regulatory standards, and explore new market territories will likely lead the charge toward a more dynamic and profitable future in the ceramic inks industry. As the market continues to evolve, staying ahead through continuous innovation and strategic planning will be key to capturing and sustaining market leadership.