Table of Contents

Introduction

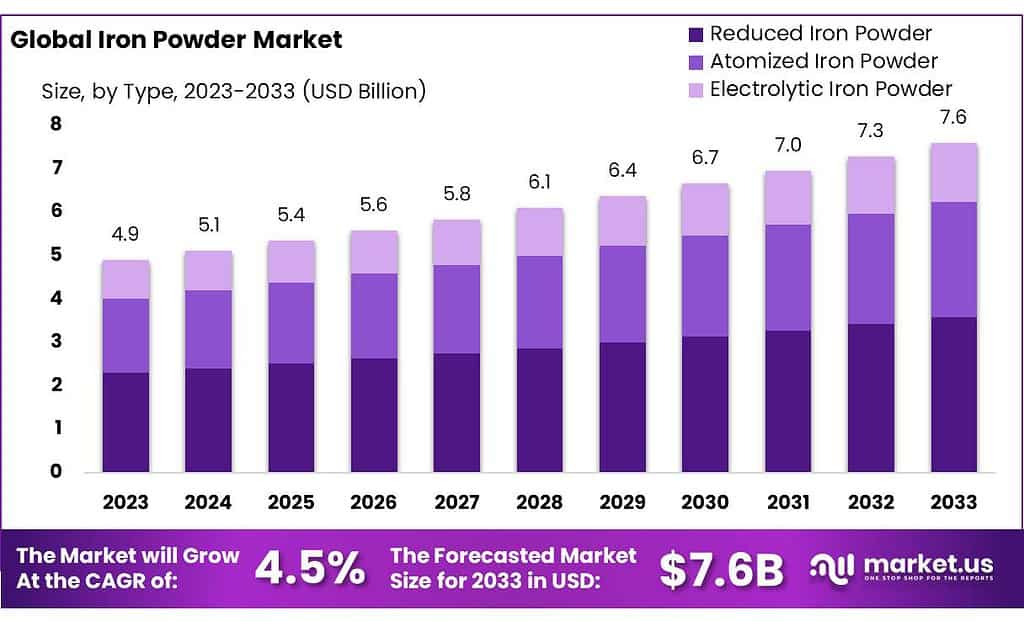

The global iron powder market is set to experience significant growth, expanding from USD 4.9 billion in 2023 to an estimated USD 7.6 billion by 2033, with a compound annual growth rate (CAGR) of 4.5% over the forecast period. This growth is driven by increasing applications of iron powder in various industries, including automotive, construction, and manufacturing, where it is used in metal parts fabrication and as a raw material in the sintering process. Additionally, the rising demand for iron powder in the production of magnetic and electronic components contributes to market expansion.

However, the market faces challenges such as the volatility of raw material prices and environmental concerns related to mining and iron powder production. Despite these challenges, recent advancements in production technologies have improved the efficiency and quality of iron powder, making it suitable for high-precision applications. Manufacturers are also focusing on developing eco-friendly production methods to address environmental concerns, which is anticipated to provide new opportunities for growth in the iron powder market.

JFE Steel Corporation has made significant strides in enhancing its production capabilities to meet the growing global demand for high-quality iron powder. Recently, the company has focused on expanding its market share by improving product quality and developing new applications, particularly in the automotive sector, where iron powder is used in components like gears and bearings. Their strategic investments in technology have positioned JFE Steel as a leader in the iron powder market, ensuring they remain competitive in both domestic and international markets.

Höganäs AB, a leading manufacturer of iron powder, has recently launched several new products designed to meet specific industry needs, such as powders optimized for additive manufacturing and electromagnetic applications. These innovations are part of Höganäs AB’s strategy to cater to niche markets and expand its customer base. Furthermore, the company has been actively involved in sustainability initiatives, aiming to reduce the environmental impact of their production processes and products, which is increasingly important to clients and regulatory bodies.

Reade International Corporation has strengthened its position in the iron powder market through strategic partnerships and acquisitions, aiming to enhance its supply chain and increase its product offerings. This approach has enabled Reade to provide a broader range of iron powder grades and specifications, catering to specialized requirements across industries such as electronics, manufacturing, and chemicals. Their commitment to quality and customer service continues to drive their growth and reputation in the market.

Industrial Metal Powders has recently invested in upgrading its production facilities to boost capacity and efficiency in response to rising demand from sectors such as automotive and construction. The company has also focused on developing iron powders with higher purity levels and better performance characteristics, addressing the advancing technological requirements of their clients. These developments are crucial for Industrial Metal Powders to maintain a competitive edge and expand their global reach in the iron powder market.

Statistics

- Iron powder is formed as a whole from several other iron particles. The particle sizes vary anywhere from 20-200 μm.

- Presently about 0.72 tons of solid wastes per ton of crude steel is being generated out of which 0.67 tons is being utilized in one way or the other.

- About 80% of the market share of iron powder applications is swept by PM parts alone, mostly serving various automobile parts and other structural parts.

- Iron powders with coarse and fine particle size and various apparent densities and various iron-based alloy powders have been used as semi-metallic frictional and breaking materials for more than 50 years.

- Iron powders from atomization and reduction routes have high demand and occupied 72.07% and 25.21% of the global iron powder production market share respectively in the year 2015.

- Iron powder manufacturing cost analysis reveals that about 75% of the total cost comprises raw material cost, whereas other costs like energy, labor, depreciation and accessories combine to account for the left 25%.

- The theoretical reason behind this behavior is wustite being thermodynamically unstable at temperatures below 570°C, where it decomposes into magnetite and iron due to eutectoid reaction.

- No proper literature on the reduction of iron oxides to iron below 570°C using CO gas as a reducing agent is found.

- The reduction was majorly performed using hydrogen gas in the temperature range 500–1250°C.

- Composition >99% Iron

- Permeabilities up to 100

- High losses (840 mW/cm3)

- Operating frequency to >100 KHz

- BSat (Tesla) 1.5

- Curie Temperature 770˚C

Emerging Trends

- Increased Use in Additive Manufacturing: Iron powder is becoming increasingly popular in the field of additive manufacturing or 3D printing. This method allows for precise control over material properties and complex part geometries, making iron powder a valuable material for producing metal parts. The demand for iron powder in this sector is expected to grow significantly as industries continue to adopt 3D printing technologies for rapid prototyping and production.

- Growth in the Automotive Sector: There’s a rising trend of using iron powder in the automotive industry, particularly for manufacturing parts via powder metallurgy. This process is cost-effective and produces parts that are strong and wear-resistant, which are ideal for automotive applications. As the automotive industry seeks more efficient and sustainable manufacturing processes, the use of iron powder is set to increase.

- Advancements in Powder Metallurgy: Technological advancements in powder metallurgy techniques are improving the performance and quality of iron powder products. These advancements enhance the mechanical properties of the final products, making iron powder more attractive for a broader range of industrial applications, including gears, filters, and machinery components.

- Focus on Recycled Materials: With growing environmental concerns and the push for sustainable manufacturing practices, there is an increasing trend toward the use of recycled iron powder. This not only helps in reducing the environmental impact but also lowers the cost of raw materials, appealing to cost-conscious manufacturers.

- Energy Storage Applications: Iron powder is being explored as a potential medium for energy storage, particularly in renewable energy systems. Research into using iron powder as a fuel (due to its high energy density and recyclability) is gaining traction, which could open new applications in large-scale energy storage and generation.

Use Cases

- Automotive Components: Iron powder is extensively used in the automotive industry for the production of gears, bearings, and other engine components through the powder metallurgy process. This method offers high precision and cost-effectiveness, making it ideal for mass production. The automotive sector, which is forecasted to grow significantly, relies on iron powder for its ability to produce durable and reliable parts.

- Magnetic Materials: Iron powder is a key component in the manufacturing of magnetic products such as cores for electric motors, transformers, and inductors. These applications benefit from the magnetic properties of iron powder, which is crucial in the electronics and automotive industries. The global market for magnetic materials is projected to expand as demand for electronics and electric vehicles increases.

- Welding Applications: Iron powder is used in certain types of welding electrodes. It acts as a filler material that increases the efficiency of the welding process by promoting smoother, more consistent welds and increasing the deposition rate. This application is critical in construction and industrial fabrication, where high-strength joins are required.

- Food Fortification: Iron powder is used to fortify foods to increase their nutritional value, especially to combat iron deficiency in diets. It is an effective way of adding iron to cereals, flour, and other staple foods without significantly altering their taste or appearance. The global food fortification market is growing as health awareness increases.

- Water Purification: Iron powder is employed in water treatment processes to remove impurities and pollutants. It acts as a reducing agent in chemical processes that treat industrial effluents and municipal wastewater, helping to purify water by removing toxic substances and heavy metals.

- Metal Replacement and Weight Reduction: In industries looking to reduce weight while maintaining strength, such as aerospace and defense, iron powder is used to produce lightweight but strong components. The unique properties of iron powder allow for the creation of parts that are lighter than those made from solid iron or steel.

Major Challenges

- Supply Chain Disruptions: The iron powder industry often faces challenges related to the volatility of raw material supplies. Disruptions in the supply chain can occur due to geopolitical issues, trade disputes, or natural disasters, affecting the availability and price of raw materials. This unpredictability can lead to production delays and increased costs, impacting manufacturers’ ability to meet demand consistently.

- High Production Costs: Producing high-quality iron powder is a capital-intensive process that involves substantial energy consumption and sophisticated equipment. The cost of energy, particularly in regions where electricity prices are high, can significantly affect overall production costs. Additionally, the maintenance of equipment and technology upgrades add further financial burdens to producers.

- Environmental Regulations: Iron powder manufacturing involves processes that can have considerable environmental impacts, including emissions and waste generation. Stricter environmental regulations globally mean companies must invest in cleaner production technologies and waste management systems, which can be costly. Compliance with these regulations is essential but can increase operational costs and reduce profit margins.

- Competition from Alternative Materials: Iron powder faces competition from other metals and alloys that might offer better performance or cost advantages in specific applications. For example, composite materials or advanced polymers are being used as substitutes in areas like automotive and aerospace for weight reduction and efficiency gains. This competition can limit the growth of the iron powder market in certain sectors.

- Technological Advancements: While technological advancements can open new markets for iron powder, they also require continuous investment in research and development to keep up with industry changes. Manufacturers need to innovate their product offerings to meet the evolving requirements of end-users, which can be challenging and resource-intensive.

Market Growth Opportunities

- Expansion in Additive Manufacturing: The growing adoption of additive manufacturing or 3D printing across industries presents a significant opportunity for the iron powder market. Iron powder is increasingly used to print complex and lightweight parts for automotive, aerospace, and medical applications. As 3D printing technology advances and becomes more cost-effective, the demand for iron powder is expected to rise, especially in markets that value customization and rapid prototyping.

- Advancements in Powder Metallurgy: Iron powder is a key component in powder metallurgy, which offers advantages such as reduced wastage and high precision in manufacturing parts for automotive and machinery applications. Technological advancements in this sector can expand the use of iron powder in producing more complex and performance-specific components, potentially increasing its market share in industrial manufacturing processes.

- Electromagnetic Applications: The electromagnetic industry, which includes the manufacture of motors, inductors, and transformers, relies heavily on iron powder for its magnetic properties. As the global demand for more efficient electronic and electrical devices grows, there is an increasing opportunity for iron powder to play a critical role in electromagnetic applications, driving further market growth.

- Energy Storage Solutions: Iron powder has potential applications in energy storage and generation. Research into using iron powder as a renewable fuel for heat generation showcases an innovative approach to storing and generating energy. The concept of “metal fuels,” which proposes using metals like iron as a clean, recyclable fuel, could open new avenues for the use of iron powder in sustainable energy solutions.

- Increased Demand from Developing Regions: Developing regions with growing industrial and manufacturing sectors, such as Asia-Pacific and Latin America, offer expansive markets for iron powder. Increased infrastructure development, rising automotive production, and industrialization in these regions are expected to drive the demand for iron powder, providing substantial growth opportunities for producers.

Key Players

JFE Steel Corporation is a prominent player in the iron powder market, renowned for its high-quality and consistent iron powder products, widely used in powder metallurgy and various welding applications. Leveraging advanced manufacturing technologies, JFE has enhanced its product range to meet stringent specifications required by the automotive and machinery industries. The company’s commitment to innovation and quality assurance helps it maintain a competitive edge in the global market, fulfilling the evolving demands of modern manufacturing practices.

Höganäs AB, based in Sweden, is the world’s largest producer of iron and metal powders. The company excels in producing a wide range of iron powders that are key components in automotive components, electromagnetic applications, and additive manufacturing. Höganäs AB is at the forefront of developing new applications for iron powder, driving advancements in 3D printing technologies and sustainability initiatives. Their focus on environmental stewardship and technological innovation positions them as a leader in the iron powder industry, pushing boundaries in both product quality and application diversity.

Reade International Corporation is a key supplier in the iron powder market, known for its diverse range of metal powders, including iron, used across various industries. The company specializes in customizing its products to meet specific industry requirements, from chemical manufacturing to electronics and defense. Reade’s commitment to quality and its ability to supply a broad spectrum of particle sizes and shapes enhances its appeal to clients seeking precision and reliability in iron powder applications.

Industrial Metal Powders (IMP) India Pvt. Ltd. is recognized for its high-purity iron powders, primarily serving sectors such as chemical, metallurgy, and electronics. With a focus on sustainable manufacturing practices, IMP is dedicated to producing iron powders that are both environmentally friendly and of the highest quality. Their products are crucial for applications requiring high purity, such as in the manufacture of sintered components and magnetic materials. IMP’s commitment to technological advancement and customer satisfaction solidifies its position as a trusted leader in the global iron powder market.

American Element is a major supplier of advanced materials, including a broad range of iron powders used in various high-tech and industrial applications. Their iron powders are particularly favored for use in metallurgy, electronics, and chemical synthesis due to their high purity and customizable particle sizes. American Elements is known for its commitment to innovation, frequently introducing new formulations that enhance the performance of traditional iron powders, making them suitable for cutting-edge manufacturing processes and research applications.

ATI (Allegheny Technologies Incorporated) is a global manufacturer of technically advanced specialty materials, including iron powder, primarily used in aerospace, defense, and medical industries. ATI focuses on producing high-quality iron powders that offer exceptional performance in challenging environments, such as high-temperature or corrosive conditions. Their products are critical in applications demanding high strength and durability, such as powder metallurgy and additive manufacturing. ATI’s dedication to quality and innovation makes them a leader in supplying specialized materials for critical and complex applications.

Ashland is not primarily known for its involvement in the iron powder sector but is a global leader in specialty chemicals, focusing on innovative chemical solutions across a variety of industries. If Ashland were to venture into the iron powder market, it would likely leverage its extensive expertise in chemistry and materials science to develop specialized iron powder formulations that could be used in applications such as catalysts, pharmaceuticals, or advanced coatings, providing high-performance products that meet specific customer needs.

BASF, one of the world’s leading chemical companies, has diversified its product range to include materials applicable in the iron powder market, particularly focusing on the chemical industry where iron powder is used as a catalyst. Their research and development capabilities enable BASF to enhance the properties of iron powders, making them suitable for a broad range of applications including chemical synthesis and industrial processes. BASF’s commitment to sustainability and innovation also sees the company developing iron powders that can be used in environmentally friendly processes.

Rio Tinto Metal Powders is a division of the global mining giant Rio Tinto, specializing in the production of high-quality metal powders, including iron powder. Their products are widely used in powder metallurgy for producing parts and components that require high strength and reliability, such as in automotive and industrial machinery. Rio Tinto’s commitment to sustainability and its extensive mining and processing expertise allow it to offer consistent and reliable iron powder products to customers worldwide, supporting industries that require precision and durability in their applications.

SAGWELL USA Inc. is a notable provider in the iron powder market, specializing in the production and supply of iron powders used in various industrial applications. Known for its commitment to quality, SAGWELL offers a range of iron powders suited for powder metallurgy, sintering, and other manufacturing processes. The company leverages advanced production techniques to ensure the high purity and consistency of its products, making it a trusted partner for industries that require reliable and high-performance iron powder solutions for their advanced manufacturing needs.

Serena Nutrition is not traditionally associated with the iron powder sector but focuses on nutritional supplements and health products. Should Serena Nutrition venture into the iron powder market, it would likely use iron powder as a fortifying agent in dietary supplements aimed at addressing iron deficiency. With a reputation for quality and natural ingredients, Serena Nutrition could innovate by offering iron-enriched products that support health and wellness, tapping into the growing market for nutritional enhancements with essential minerals.

Belmont Metals, based in Brooklyn, New York, is a veteran in the iron powder market, offering a broad range of metal powders, including iron, for various industrial applications. Known for its versatility and quality, Belmont Metals provides iron powder that is used in powder metallurgy, magnetic materials, and chemical processes. Their long-standing expertise ensures high-purity products tailored to customer specifications, supporting industries such as electronics, manufacturing, and construction. Belmont’s commitment to technological innovation and customer service continues to strengthen its position in the metal powders market.

CNPC Powder is a rapidly growing company in the iron powder sector, known for its comprehensive range of metal powders, including iron, copper, and aluminum powders. Specializing in powder metallurgy, CNPC Powder supplies high-quality materials that are essential for manufacturing sintered parts and components used in automotive, aerospace, and electronics industries. Their focus on technological innovation and quality control has established CNPC as a reliable supplier capable of meeting the rigorous demands of modern manufacturing processes.

Conclusion

Additionally, sustainable construction practices are gaining momentum, leading to increased use of eco-friendly materials such as mineral fibers and gypsum in ceiling tiles. These materials not only provide practical benefits such as noise reduction and thermal insulation but also align with the industry’s push toward greener solutions. The market is expected to see further innovations, including lightweight, durable designs that cater to both aesthetic and functional needs.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)