Table of Contents

Introduction

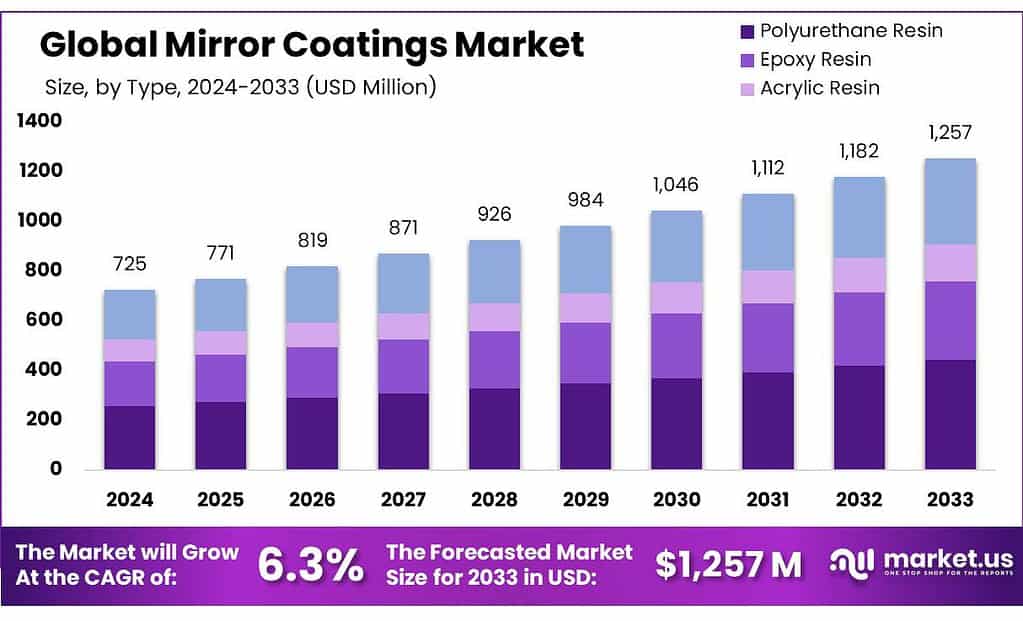

The global mirror coatings market is anticipated to grow from USD 725 million in 2023 to USD 1257 million by 2033, progressing at a compound annual growth rate (CAGR) of 6.3%. This growth is driven by robust demand in various sectors including automotive, construction, and solar energy applications. The Asia Pacific region dominates the market, fueled by rapid industrialization and urbanization, particularly in emerging economies like China, India, and Japan. This region’s growth is supported by the expansion of the automotive and construction industries, as well as increasing investments in renewable energy sources such as solar power.

Several factors contribute to the expansion of the mirror coatings market. Increased application in water and wastewater treatment facilities, along with a rising demand from the construction sector for modern living spaces, are significant growth drivers. The coatings are extensively used in the building and construction sector to enhance aesthetic appeal and energy efficiency. Technological advancements, such as the development of eco-friendly and energy-efficient coatings, also support market growth, aligning with global sustainability trends.

However, the market faces challenges such as fluctuations in raw material prices and the complexity of production processes, which can lead to inconsistencies in coating quality and performance. The need for high precision in the formulation and application of advanced coatings makes the manufacturing process intricate and potentially costly.

Recent developments in the market include innovations aimed at improving the sustainability of paints and coatings, as demonstrated by Arkema at Paint India 2024. Additionally, partnerships such as the one between Diamon-Fusion International and Glass.com indicate a trend towards direct consumer access to DIY coating solutions, enhancing the reach and application of mirror coatings. These advancements reflect the industry’s response to market demands and challenges, contributing to the ongoing growth and evolution of the mirror coatings sector.

Abrisa Technologies has significantly advanced its capabilities in precision glass solutions and optical coatings. Notably, they have expanded their precision sawing, wafer dicing, and grooving capabilities, which are critical for a broad array of technical glass applications. Moreover, Abrisa has recently introduced new capabilities for ultra-thin glass processing and advanced coatings for various applications such as ITO heaters and imaging sensors.

AccuCoat Inc. continues to specialize in providing optical coatings across a range of applications. Their offerings include anti-reflective, mirror, polarizing, and filter coatings, which are applied to materials such as glass, metals, and polymers. AccuCoat’s expertise in custom and standard coatings allows them to cater to specific industry needs, particularly in high-precision optical components.

Key Takeaways

- The global mirror coatings market is projected to grow from USD 725 million in 2023 to USD 1,257 million by 2033, with a CAGR of 6.3%.

- Polyurethane resin dominates the market, holding a 35.4% share in 2023, driven by its superior adhesion and chemical resistance, particularly in automotive and architectural applications.

- Architectural applications accounted for over 44.1% of the market in 2023, benefiting from the demand for energy-efficient coatings in modern building designs.

- Solvent-based coatings led the market with a 44.5% share in 2023, known for their high performance in automotive and architectural applications, despite growing environmental concerns.

- Silver-based coatings held a 55.6% market share in 2023, valued for their exceptional reflectivity, widely used in automotive rear-view mirrors and decorative applications.

- North America dominates with a 36.3% market share, valued at USD 263.2 billion, primarily due to strong demand in the construction, automotive, and solar energy sectors.

Mirror Coatings Statistics

- Another type is the high-reflector coating, which can be used to produce mirrors that reflect greater than 99.99% of the light that falls on them.

- Reflection coefficients of surfaces can be reduced to less than 0.2%, producing an antireflection (AR) coating.

- The level of reflectivity can also be tuned to any particular value, for instance to produce a mirror that reflects 90% and transmits 10% of the light that falls on it, over some range of wavelengths.

- Such coatings can reduce the reflection for ordinary glass from about 4% per surface to around 2%.

- These optics provide >96% average reflectance from 800 nm to 20 μm.

- 70% isopropyl alcohol diluted in water (no more than 50/50 mix if used on a regular basis)

- The mirror layer also provides 100% UV light protection, and by bouncing excess light from your eyes, it allows you to focus more clearly on objects, colours and contrasts.

- The remaining 50% of visible light striking the lens passes between the reflective particles. Some of this light is absorbed by the underlying lens tint. The remainder passes through the lens to the eye.

- The simplest and most common mirror coating is a thin layer of metal. A 100-nm layer of aluminum or silver makes an excellent reflector for the visible spectrum. Aluminum reflects about 90 percent of the light across the visible spectrum, while silver reflects about 95 percent.

- The surface quality of a mirror, or its smoothness, is measured in terms of scratches and digs that are still present after polishing. A scratch/dig specification of 80/50 is fairly routine, while a specification of 20/10 is much better, but more expensive.

- For a reflectance of 85 percent, a system with five mirrors would have a throughput of only 44 percent.

Emerging Trends

- Sustainability and Eco-friendliness: There’s a notable shift towards developing mirror coatings that minimize environmental impact. Manufacturers are incorporating green technologies and focusing on reducing volatile organic compounds (VOCs). This aligns with a broader push towards renewable energy sources and sustainability in production processes.

- Technological Advancements: The integration of smart coatings is becoming more prevalent. These smart coatings offer additional functionalities such as anti-fogging, self-cleaning, and even augmented reality features, meeting the rising demand for multifunctional materials across various industries.

- Customization and Personalization: Manufacturers are increasingly offering a range of coatings with varied aesthetic properties, catering to specific design preferences in sectors like architecture, interior design, and automotive. This trend is supported by a growing collaboration between coating manufacturers and end-use industries to develop tailor-made solutions.

- Material Innovation: Materials like aluminum and silver are prominently used due to their high reflectivity and durability. Innovative materials such as dielectric coatings are also being used to enhance the performance of mirror coatings.

- Deposition Technologies: Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) are leading technologies used for applying these coatings. PVD is appreciated for its high deposition rates and good adhesion, while CVD offers excellent control over film thickness and composition, suitable for precision applications.

Use Cases

- Astronomy and Telescopy: High-performance mirror coatings, such as protected silver and aluminum, are crucial in telescopes, including those used in major observatories and space telescopes like the James Webb Space Telescope. These coatings are selected for their ability to reflect light across different wavelengths, which is essential for capturing clear, detailed images of celestial bodies.

- Automotive Industry: Mirror coatings are applied to automotive components, such as rearview mirrors, to enhance reflectivity and durability. Enhanced aluminum coatings, for instance, are used for their high reflectance and resistance to environmental factors.

- Architectural Applications: In the building and construction industry, mirror coatings are applied to glass in buildings to improve aesthetics and energy efficiency. Coatings like silver and aluminum reflect sunlight, reducing heat absorption and cooling costs.

- Scientific and Industrial Instruments: Mirror coatings are integral to the function of various scientific instruments, such as microscopes and lasers, where they are used to direct light precisely and efficiently. These applications often require custom coatings tailored to specific optical needs, such as high reflectivity or specific wavelength passbands.

- Medical and Dental Equipment: In the medical field, especially in dental mirrors, rhodium coatings are used because of their durability and high reflectivity. These mirrors assist in accurate patient examinations under intense lighting conditions without distorting the reflected light.

- Decorative Purposes: Gold and copper mirror coatings are often used for decorative applications due to their vibrant colors and high reflectivity. These coatings can also be found in interior design elements to create a sense of space and light.

- Defense and Aerospace: Mirrors with highly reflective coatings are used in defense and aerospace applications, where precision and reliability under harsh conditions are paramount. The mirrors used in these fields often undergo rigorous specifications to meet the high standards required for performance.

Major Challenges

- Fluctuations in Raw Material Prices: The cost of raw materials needed for mirror coatings, such as metals and chemicals, can vary widely. These fluctuations can affect the overall production costs, making budgeting and pricing strategies more complex for manufacturers.

- Technological Complexity: The production of advanced mirror coatings involves intricate chemical processes and sophisticated technologies. Achieving high-quality, consistent results requires precise control over various parameters. This complexity can increase production costs and necessitate the need for specialized equipment and skilled personnel, potentially limiting the ability of manufacturers to scale operations.

- Regulatory Compliance: Compliance with environmental regulations is increasingly becoming a challenge for the industry as there is a push towards reducing the use of volatile organic compounds (VOCs) and other harmful substances in manufacturing processes. Adhering to these regulations can require significant investment in cleaner technologies and processes.

- Market Saturation and Competitive Pressure: The mirror coatings market is highly competitive, with numerous players ranging from large corporations to specialized companies. This competition can lead to price wars, reduced profit margins, and the need for continuous product innovation and differentiation to maintain market share.

- Sustainability and Eco-Friendly Innovations: There is a growing trend toward the development of sustainable and eco-friendly products. This shift in consumer preference is pressuring manufacturers to innovate with green technologies that minimize environmental impact while still meeting performance standards.

Market Growth Opportunities

- Technological Innovations and Smart Mirrors: The integration of digital technologies such as touch screens and augmented reality into mirrors is creating new applications and driving demand. This includes smart mirrors which are becoming increasingly popular in residential, commercial, and healthcare settings due to their enhanced functionality.

- Sustainability and Energy Efficiency: There’s a rising demand for coatings that contribute to sustainability, particularly in the construction and automotive industries. This includes the development of coatings that improve energy efficiency of buildings by reflecting UV rays and reducing cooling costs.

- Growth in the Automotive Sector: The automotive industry is a significant driver of the mirror coatings market, with innovations in mirror coatings enhancing safety and aesthetic appeal of vehicles. The rising production of electric vehicles and advancements in automotive design are expected to further boost the market.

- Expansion in Construction and Architectural Applications: As urbanization continues to increase, especially in Asia Pacific, there is a growing demand for mirror coatings in residential and commercial construction. These coatings are used for aesthetic and functional purposes such as in windows, facades, and interior decorations.

- Renewable Energy Applications: There is also a notable opportunity for mirror coatings in the renewable energy sector, particularly in solar power, where highly reflective mirrors are essential for efficient energy production.

- Regional Market Expansion: The Asia Pacific region is experiencing rapid growth due to urbanization and increased construction activities, which is likely to continue. This region, along with North America and Europe, presents significant opportunities for market expansion due to their large automotive and construction industries.

Key Players Analysis

In 2024, Abrisa Technologies highlighted its advancements in the mirror coatings sector by enhancing its capabilities in ultra-thin glass processing and developing coatings for various high-tech applications such as NVIS (Night Vision Imaging System), ITO (Indium Tin Oxide) heaters, and sensing technologies. These innovations cater to a wide range of industries including automotive, aerospace, and digital display sectors, providing tailored solutions that address specific optical performance requirements while ensuring durability and precision in their applications.

AccuCoat Inc. specializes in a variety of optical coatings across multiple applications, offering solutions such as anti-reflective, polarizing, and mirror coatings for different substrates including glass, metals, and polymers. Their ability to provide both standard and customized coating solutions allows them to meet specific industry needs, enhancing optical performance in sectors ranging from medical devices to military and industrial applications.

In 2023, Arkema Group demonstrated resilience and innovation within the mirror coatings market, particularly emphasizing sustainability and high-performance solutions. Their focus on advanced material sciences enabled them to support industries like automotive and construction with cutting-edge coating technologies. Arkema is poised for growth in 2024, with plans to expand their sustainable offerings and improve market positions through strategic initiatives aimed at reducing environmental impact and enhancing product performance.

CASIX specializes in precision optics and photonics, providing specialized mirror coatings that enhance the performance and durability of optical components. Their expertise in fabricating and coating high-precision optics allows them to serve critical applications across telecommunications, industrial, and defense sectors. CASIX’s commitment to quality and innovation positions them as a key player in the mirror coatings market, catering to both standard and customized product needs.

In 2024, Diamon-Fusion International Inc. (DFI) expanded its offerings by entering a partnership with Glass.com to sell its DIY hydrophobic coatings and glass cleaning products directly to consumers online. This strategic move leverages DFI’s reputation for innovative protective glass coatings that enhance durability and clarity, furthering their reach within the consumer market by making their products more accessible directly through an established online platform.

Dynasil Corporation continues to excel in the mirror coatings sector, particularly noted for their contributions to scientific and industrial applications. Their expertise in developing high-precision optical coatings is crucial for various sophisticated instruments where exacting standards of reflectivity and performance are demanded. This focus on high-performance coatings for niche applications allows Dynasil to maintain its position as a critical supplier in sectors that rely heavily on precise optical solutions.

In 2024, Edmund Optics Inc. continued to enhance its offerings in the mirror coatings market with a broad array of metallic coatings optimized for diverse spectral applications. Their products range from protected aluminum, suitable for visible applications, to protected gold, ideal for near-infrared (NIR) and infrared (IR) applications. The company’s focus on providing high-precision optical components caters to specialized sectors requiring meticulous detail to optical performance.

FENZI SPA has positioned itself as a key player in the mirror coatings market, specializing in the production of paints, enamels, and coatings for the glass industry. Their products are pivotal in various applications, including architectural, automotive, and decorative mirrors, leveraging their expertise to offer both aesthetic and functional enhancements to glass surfaces. FENZI’s commitment to quality and innovation allows them to meet stringent industry standards and client expectations.

In 2024, Guardian Industries continues to innovate in the mirror coatings sector with their Guardian UltraMirror® glass. This product stands out for its exceptional clarity and resistance to corrosion, which makes it suitable for use in environments where maintaining a pristine appearance is essential, such as in retail or hospitality settings. The UltraMirror® glass is engineered to resist degradation from household cleaners, humidity, and other environmental factors, ensuring durability and sustained aesthetic appeal.

General Optics (Asia) Limited specializes in precision optical components, including mirror coatings that cater to high-tech industries such as telecommunications, defense, and aerospace. Their focus is on delivering high-quality products that meet rigorous industry standards, ensuring reliability and performance across various applications. This commitment positions them as a key player in the Asian market for specialized optical solutions.

In 2024, Jenoptik continues to lead in the mirror coatings market, particularly focusing on polymer optics. They utilize metals like aluminum, silver, and gold to create coatings that are not only cost-effective but also highly reflective across a wide range of wavelengths. These coatings are applied to complex three-dimensional shapes, making them ideal for diverse applications in industries such as healthcare, automotive, and lighting. Jenoptik’s approach emphasizes environmental durability and cost efficiency, ensuring that their mirror coatings are both high-quality and adaptable to specific customer needs

NBC Coating, on the other hand, stands out in the mirror coatings industry for their high-reflectivity mirrors and scratch-resistant coatings. Their focus on providing niche applications allows them to offer innovative solutions that cater to specialized needs within the market. NBC Coating’s expertise includes developing mirror coatings that are tailored to enhance performance while maintaining environmental responsibility, aligning with the growing global demand for sustainable and efficient coating solutions.

In 2024, North American Coating Laboratories (NACL) continues to be a leader in the mirror coatings market, offering a wide range of custom-designed reflective coatings. These coatings are tailored for various applications across industries such as automotive, avionic, and aerospace, focusing on both aesthetic and functional uses. Their expertise spans from cosmetic applications on ophthalmic lenses to robust, functional applications in demanding environments. NACL’s capabilities include developing highly reflective coatings for multiple substrates at specific wavelengths, ensuring versatility and high performance in their coating solutions.

PearlNano LLC specializes in innovative mirror coatings that incorporate nanotechnology to enhance their performance. While specific, recent updates on their activities and offerings in the mirror coatings sector aren’t detailed, their focus remains on producing high-quality, durable coatings that offer superior protection and reflectivity. PearlNano’s products are tailored to meet the demands of various industries, emphasizing scratch resistance and longevity.

Conclusion

The mirror coatings market is set to witness robust growth fueled by technological advancements and rising demand across various industries. The integration of digital and smart technologies into mirror products is creating new applications and driving innovation, particularly in smart mirrors that offer enhanced functionality for both residential and commercial uses. Additionally, the push towards sustainability is promoting the development of eco-friendly and energy-efficient coatings, aligning with global efforts to reduce environmental impacts.

Key industries such as automotive and construction are pivotal growth areas, with rising urbanization and infrastructure developments, especially in the Asia-Pacific region, driving significant market expansion. As the market continues to evolve, the focus on innovative coating solutions that provide durability, aesthetic appeal, and functional benefits is expected to intensify, offering numerous opportunities for industry participants to capitalize on the emerging trends and meet the sophisticated demands of modern applications.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)