Table of Contents

Introduction

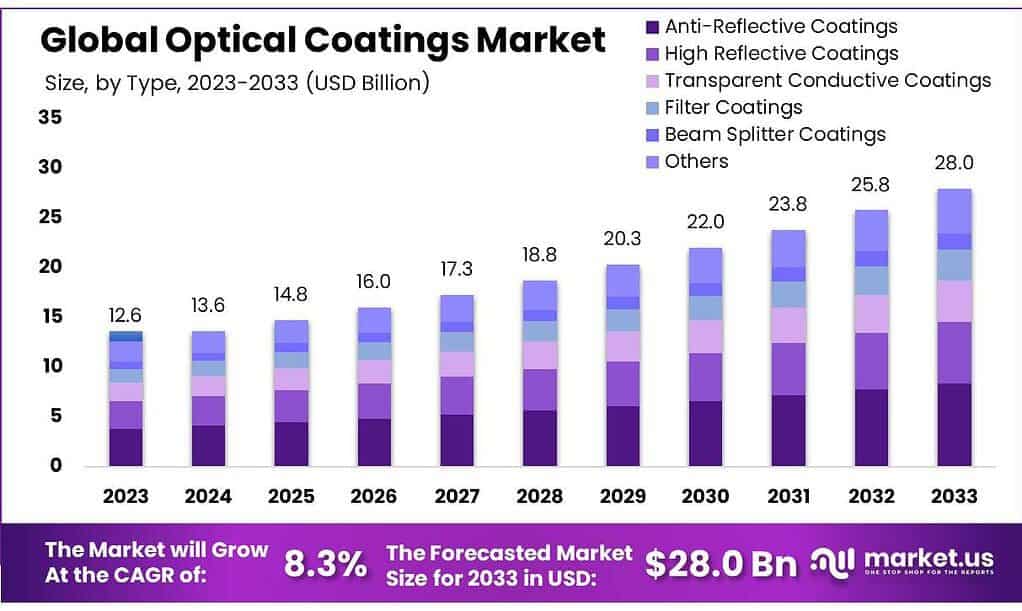

The global optical coatings market is poised for significant growth, projected to expand from USD 12.6 billion in 2023 to USD 28.0 billion by 2033, reflecting a robust compound annual growth rate (CAGR) of 8.3% over the forecast period.

This growth trajectory is primarily fueled by increasing demands across various industries, notably electronics, and semiconductors, which leverage these coatings for enhanced performance and durability of devices like smartphones and cameras.

A range of factors drives this market’s expansion. Technological advancements in optical deposition and fabrication processes are central to meeting the rising requirements for more sophisticated optical solutions. The solar power sector also significantly contributes to market growth, with innovations aimed at improving photovoltaic panel efficiencies through advanced coatings.

However, the market faces challenges, including stringent government regulations and the environmental durability of optical coatings, which require ongoing adaptation and innovation from manufacturers. Furthermore, volatility in raw material prices poses a considerable constraint, affecting production costs and market stability.

Reynard Corporation, a leading provider in the optical coatings market, has been actively advancing its capabilities in custom optics and thin-film coatings. The company specializes in producing high-performance optics tailored to various applications, including aerospace, defense, and medical industries.

They have demonstrated continued innovation, as seen in their development of gradient filters and advanced anti-reflective coatings, which are crucial for enhancing optical system performance across multiple industries.

Key Takeaways

- The Optical Coatings Market is anticipated to grow significantly, reaching around USD 28.0 billion by 2033 from USD 12.6 billion in 2023, representing a robust CAGR of 8.3%.

- Based on ‘Product’, the ‘Anti-Reflective Coatings’ segment accounted for the majority revenue share of more than 30.1% in 2023.

- Vacuum deposition This method dominates due to its versatility in applying coatings in a controlled environment.

- In terms of ‘Application’, the ‘Consumer Electronics’ segment led this market, accounting for a revenue share greater than 32.0% in 2023.

- North America dominated the market for optical coatings and was responsible for 37.8% of this industry’s revenue share in 2023.

Optical Coating Statistics

Advancements in Optical Coating Applications

- The $3 million grant, contained in the Omnibus Appropriations Act of 2024 and secured by U.S. Sen. Jeanne Shaheen, D-N.H., is designated for programs focused on ultra-precision manufacturing, optics, and thin-film coatings.

- Shaheen secured more than $100 million in Congressionally Directed Spending for state projects. Among several priorities the senator championed and secured resources to help address are the childcare crisis, housing shortage, a wage hike for service members, clean water, transportation, and mental health education.

- MoreSun, which can be applied to any solar array, increases total energy output by up to 4.7% and increases power from direct axis light by up to 3.8%, according to the company.

- The coating is formulated with Pellucere’s proprietary Talus Dirt Rejection Technology and has been shown in testing to reduce the build-up of dirt, dust, and other particulates by as much as 90%.

- Nfinite Nanotech Closes $6.5 Million Seed Financing to Create Flexible Food Packaging with Nanotechnology.

High-Efficiency Optical Coating Technologies

- The optical coatings industry, already valued at more than $14 billion worldwide, is predicted to continue its expansion as more industries demand high-performance lenses that can withstand harsh conditions.

- The reflection coefficients of surfaces can be reduced to less than 0.2%, producing an antireflection (AR) coating. Conversely, the reflectivity can be increased to greater than 99.99%, producing a high-reflector (HR) coating.

- The level of reflectivity can also be tuned to any particular value, for instance, to produce a mirror that reflects 90% and transmits 10% of the light that falls on it, over some range of wavelengths

- Such coatings can reduce the reflection for ordinary glass from about 4% per surface to around 2%. These were the first type of antireflection coating known, having been discovered by Lord Rayleigh in 1886

- The best of these coatings built up from deposited dielectric lossless materials on perfectly smooth surfaces can reach reflectivities greater than 99.999% (over a fairly narrow range of wavelengths).

- Common HR coatings can achieve 99.9% reflectivity over a broad wavelength range (tens of nanometers in the visible spectrum range).

Emerging Trends

- Growing Utilization of Anti-Reflective Coatings: There’s a surge in demand for anti-reflective coatings within sectors such as automotive, consumer electronics, and energy, particularly solar panels. These coatings are pivotal for minimizing glare and enhancing the clarity of various visual displays, including those in smartphones and vehicles.

- Enhancements in Vacuum Deposition Techniques: The vacuum deposition method continues to be the technique of choice for applying optical coatings, praised for its ability to deposit even, high-quality layers. Innovations in this technology are improving its precision and efficiency, catering to advanced optical needs.

- Advancements in Filter Coatings: The development of filter coatings is accelerating, especially to meet the specialized requirements of the healthcare, aerospace, and defense industries. These coatings are designed to manage light precisely, ensuring optimal performance in critical applications.

- Increased Applications of High-Reflective Coatings: High-reflective coatings are becoming increasingly popular across various industries, including solar energy, aerospace, and automotive. These coatings are essential for maximizing light reflection, significantly enhancing the efficiency of devices such as solar panels and optical systems.

Use Cases

- Beam Splitters in Optical Devices: Beam splitters are used to split a single beam of light into two separate beams or combine two beams into one. This application is essential in laser systems, optical microscopes, and machine vision systems, where precise light management is crucial.

- Anti-Reflective Coatings for Visual Clarity: Anti-reflective (AR) coatings are applied to surfaces like eyeglasses, camera lenses, and binoculars to minimize reflections. This enhances light transmission, improves contrast, and reduces glare, making the visual experience clearer and more comfortable.

- Protective Coatings for Optical Components: Protective optical coatings are designed to shield surfaces from scratches, environmental damage, and contaminants. These coatings are commonly used on devices such as eyeglasses and camera lenses to extend their lifespan and maintain optical performance.

- Polarizing Coatings for Glare Reduction: Polarizing films are used to manage light that enters at specific angles, reducing glare. These are particularly useful in sunglasses and display screens (like those on TVs and computers), enhancing visibility and comfort.

- High-Reflective Coatings for Enhanced Reflectivity: Reflective coatings are applied to increase the reflectivity of surfaces, which is vital for applications like telescope mirrors, automotive mirrors, and laser cavity mirrors. These coatings help in reflecting light back toward its source, improving the efficiency of optical systems.

Major Challenges

- Fluctuations in Raw Material Costs: The prices for essential materials such as titanium dioxide, indium, and precious metals used in optical coatings can be highly variable. This unpredictability can directly influence manufacturing costs, posing challenges for maintaining consistent pricing and profitability.

- Capital Intensive Production Processes: Establishing operations in the optical coatings sector often demands substantial investments in both research and development and high-tech equipment. This high entry barrier can deter new competitors and pressure existing companies to develop more cost-effective innovations.

- Compliance with Diverse Regulatory Standards: Optical coatings must meet stringent regulations that vary significantly across different regions and applications. Adhering to these varied standards demands considerable effort and resources, which can burden manufacturers, particularly those with a global presence.

- Demand for High Environmental Resistance: It is crucial for optical coatings to consistently perform well across a range of environmental conditions. Manufacturers need to continuously enhance the robustness and longevity of their coatings to meet the demands of extreme environments without degrading optical quality.

- Complexities in Application Techniques: The application process for optical coatings involves intricate techniques to achieve consistent and uniform coverage, especially over large or irregularly shaped surfaces. Perfecting this process is essential to ensure the high performance of the end product.

Market Growth Opportunities

- Boost in Consumer Electronics: As technology advances, the demand for optical coatings in consumer electronics is soaring. This growth is fueled by the need for superior displays in smartphones, tablets, and TVs, with a focus on improving both visual quality and durability. This upward trend is likely to persist as consumer demands evolve towards more advanced display technologies.

- Enhancements in Medical Technology: In the medical sector, optical coatings are becoming crucial, especially for imaging and diagnostic instruments. As the healthcare industry seeks more reliable and effective optical solutions, the demand for coatings that provide clearer and more functional devices continues to grow.

- Advances in Solar Technology: The solar energy industry is undergoing significant growth, heavily relying on optical coatings to boost the efficiency and functionality of solar panels. This reliance presents vast opportunities for the optical coatings market, aligning with the global move towards sustainable energy practices.

- Innovations in Transportation and Aerospace: Optical coatings play an essential role in the transportation and aerospace industries. They are used to improve the durability and visibility of display systems in vehicles and aircraft, and as these industries continue to embrace new technologies, the demand for high-quality optical coatings is expected to increase.

- Rising Demand in Developing Regions: The rapid industrial development in emerging markets like China, India, and Southeast Asia is propelling the demand for optical coatings. This demand spans across several sectors including construction, transportation, and consumer electronics, driven by extensive development activities and an expanding industrial base.

Key Players Analysis

- Reynard Corporation specializes in custom optical coatings and thin-film technologies, serving a wide array of industries including aerospace, defense, and medical sectors. Their expertise encompasses designing and manufacturing advanced optics tailored to specific environmental and operational requirements.

- Sigmakoki Co. Ltd, established in 1977, operates in the optical coatings sector by providing advanced optical solutions for a wide range of applications. Their offerings include multi-element optics, mirrors, beam splitters, and various types of lenses, which are integral to industries like biomedicine and telecommunications.

- SCHOTT has over 80 years of experience in manufacturing optical coatings tailored for a wide range of applications across industries like aerospace, defense, and healthcare. They utilize advanced thin-film technology to create custom solutions that meet specific customer needs, combining their vast experience with modern processing techniques to ensure high quality and performance in their optical components.

- Quantum Coating, Inc. specializes in providing high-performance optical coatings for various industries, including aerospace, military, and medical sectors. They offer a range of services from anti-reflective (AR) coatings to more complex mirror and filter coatings, demonstrating a strong focus on innovative solutions that enhance the durability and functionality of optical components.

- Jenoptik specializes in high-performance optical coatings and filters that are designed for specific applications, ranging from prototype to series production. Their products, which include antireflection, high-reflection coatings, and various optical filters, cover a wide spectral range from deep ultraviolet to far infrared. These coatings are used in various industries including semiconductor, healthcare, automotive, and digital imaging, offering enhanced quality and durability for optical components.

- PPG Industries Inc. plays a significant role in the optical coatings sector by producing a variety of advanced optical monomers and coatings. With over 70 years of expertise, PPG offers optical grade materials like the CR-39® monomer, TRIVEX®, and TRIBRID® lens materials. Their Hi-Gard® lens coatings are particularly noted for enhancing the scratch resistance of ophthalmic lenses, making them several times more durable than uncoated lenses.

- Materion is well-established in the optical coatings sector, specializing in high-precision dielectric and metal thin-film coatings for diverse applications. They produce coatings suitable for various wavelengths, from ultraviolet to far infrared, ensuring broad market coverage including defense, aerospace, and healthcare industries.

- Inrad Optics specializes in producing advanced optical coatings using a plasma-assisted deposition system. This technology allows them to create high-quality thin film coatings that can be applied to large optical components, enhancing properties such as adhesion, scratch resistance, and optical quality. Their capabilities cater to a variety of applications, including large-scale optics for telescopes and semiconductor equipment.

- Newport Corporation excels in the optical coating sector by utilizing advanced thin-film deposition processes to create high-performance optical filters. Their coatings are designed for precision, enhancing the spectral performance of various applications in life sciences, medical instrumentation, and materials analysis. Newport’s capabilities include creating bandpass, longpass, shortpass, notch, and dichroic beamsplitters, tailored for demanding uses like high-throughput screening and molecular diagnostics.

- ZEISS International is a leader in optical coatings, specializing in high-end anti-reflective and other specialized coatings. These coatings are designed to enhance optical performance across various applications, including medical devices, consumer optics, and microscopy. ZEISS leverages modern technologies and continuous innovation to maintain a competitive edge in the market, ensuring its optical components meet the highest standards of precision and quality.

- DuPont utilizes its expertise in science and technology to create advanced optical materials aimed at improving lighting performance, energy efficiency, and design flexibility in the general lighting industry. Their technology, notably used by WhiteOptics®, enhances light reflectance, which boosts the output and energy efficiency of commercial lighting fixtures significantly.

- Nippon Sheet Glass Co., Ltd. is actively involved in the optical coating sector, where they utilize advanced glass nanoimprinting techniques to create optical elements with high thermal resistance, low thermal expansion, and superior chemical resistance. Their capabilities include the production of intricate microstructures on glass that can significantly manipulate light properties, such as diffractive optical elements, which are crucial for various high-precision optical applications.

- Optimax Systems, Inc. specializes in the production of precision optics, including a comprehensive optical coating process within their state-of-the-art facilities. They provide custom solutions like anti-reflective coatings, beamsplitters, and metal mirrors across various demanding applications in sectors such as aerospace, defense, and semiconductor industries.

- Optical Coatings Technologies specializes in applying various thin-film coatings like abrasion-resistant and non-glare types, utilized across diverse industries including automotive, eyewear, and architecture. Their expertise extends to CNC profiling, enabling precise customization of coatings to meet specific industry needs, and enhancing both functionality and durability of optical components.

- Gelest Inc. is actively involved in the optical coatings sector, where they utilize silicon-based technologies to enhance optical components. They specialize in creating coatings that adjust the transmission and reflection of light, such as anti-reflective coatings for lenses and high-reflective coatings for mirrors.

Conclusion

The optical coating industry is poised for significant growth, driven by increasing demands in consumer electronics, medical technology, and renewable energy sectors. As innovations continue and emerging economies expand their industrial capabilities, the future of optical coatings looks bright, offering numerous opportunities for technological advancements and market expansion.