Table of Contents

Introduction

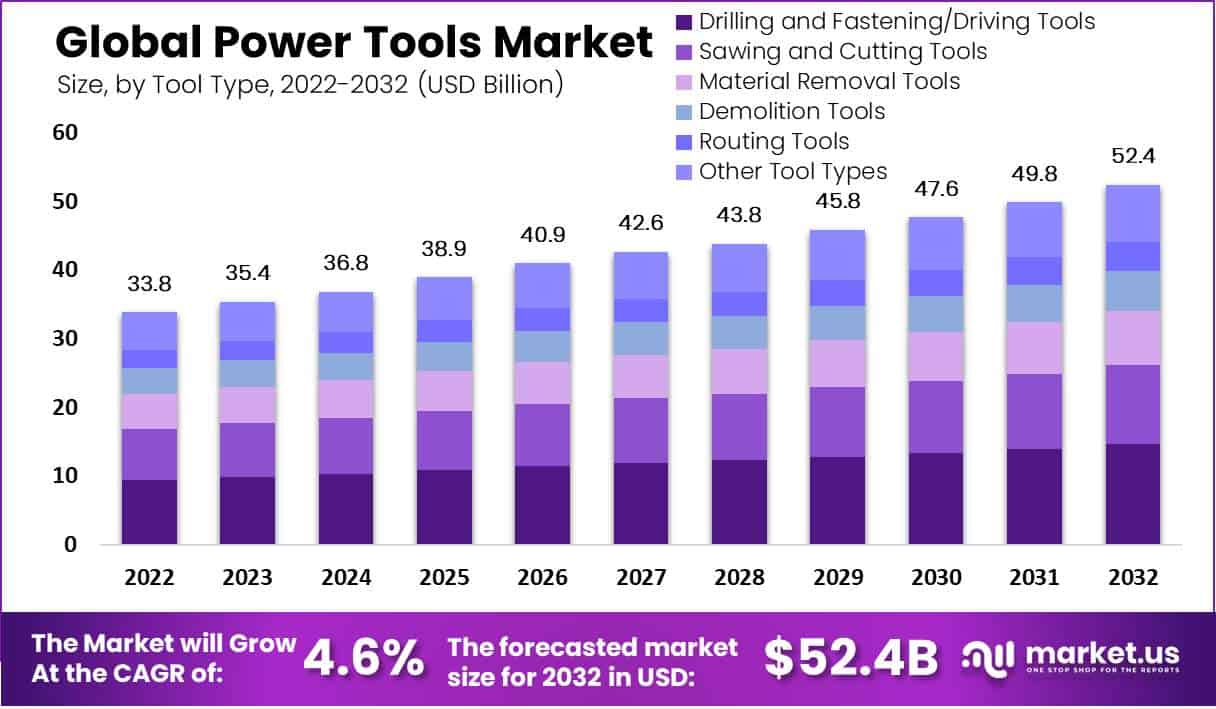

The global power tools market is poised for substantial growth, projected to expand from USD 35.4 billion in 2023 to USD 52.4 billion by 2032, with a compound annual growth rate (CAGR) of 4.6%. Power tools, which are activated by sources other than manual labor, are extensively used in various applications such as production, maintenance, repair, packaging, and do-it-yourself (DIY) activities. These tools are favored for their efficiency, ease of use, and portability, significantly reducing labor costs and enhancing productivity.

Several factors are driving the growth of the power tools market. The rising demand for power tools in the automotive and manufacturing sectors is a significant contributor. These tools are essential in assembly lines and production processes, enabling faster job completion and reducing operational time. The construction industry also heavily relies on power tools like drills, wrenches, and sanders, further fueling market growth. Technological advancements, particularly the increasing adoption of cordless tools that offer greater mobility and extended operating hours, are expected to bolster the market substantially over the forecast period.

Despite the promising growth prospects, the market faces several challenges. High maintenance costs for power tools, especially those with moving parts, and fluctuations in raw material prices are significant hurdles. The volatility in the prices of materials like steel, metal, and aluminum, which are essential for manufacturing power tools, can impact market stability. Additionally, the cost of importing these materials can fluctuate due to exchange rates and market conditions, posing a challenge to consistent growth.

Recent developments in the market include the growing integration of smart technology and ergonomic designs in power tools, enhancing their accessibility and safety. The Asia-Pacific region, particularly countries like China and India, dominates the market, accounting for a significant share of global revenues. This regional dominance is driven by rapid urbanization, industrialization, and technological advancements in the industrial sector. Key industry players like Atlas Copco AB, Emerson Electric Co., and Hilti Corporation are continuously innovating to maintain their competitive edge in this dynamic market.

Power Tools Statistics

- Asia-Pacific region holds about 35% of the global market for power tools.

- North America and Europe account for about 32% and 29% of the market, respectively.

- The rest of the world accounts for a little over 4% of the global power tools market.

- The U.S. is the largest single market, with about 29% of the global total.

- China follows the U.S. with approximately 20% to 22% of the market share.

Purchase Preferences and Safety Statistics

- Most contractors (59%) purchase power tools from industrial supply houses, and 51% from home centers.

- Plumbing wholesalers and the Internet are preferred by 39% and 37% of contractors, respectively.

- Around 27% of respondents purchase tools at hardware stores, while 19% utilize catalogs.

- The incident rate for non-fatal injuries at work due to contact with objects or work equipment is 25.5 cases per 10,000 workers.

- Contact with objects or equipment leads to approximately 700 deaths annually across all industries.

Usage and Sales Performance Statistics

- 84% of respondents use 18V battery packs for their cordless power tools, while 12V packs are used by 26%.

- In the accessories market, about 85% to 90% is accounted for by the professional market.

- Bosch Power Tools achieved sales of 5.1 billion euros across over 190 countries in 2020.

- The company saw a double-digit sales growth in about 30 sales organizations in 2020.

- Following currency adjustments, Bosch’s turnover in Europe increased by a total of 13 percent in 2020.

Emerging Trends

- Integration of Smart Technology: Power tools are increasingly incorporating smart technology features such as Bluetooth connectivity, IoT integration, and data tracking capabilities. These innovations enable users to monitor tool performance, receive maintenance alerts, and optimize usage through mobile apps and cloud-based platforms. This integration enhances efficiency, safety, and user convenience.

- Rise of Cordless Tools: The shift towards cordless power tools continues to gain momentum. Advancements in battery technology have led to longer battery life, faster charging times, and increased power output. Cordless tools offer greater flexibility and mobility, making them highly attractive for both professional and DIY users. The adoption of lithium-ion batteries, in particular, has been a game-changer, providing robust performance and durability.

- Ergonomic and User-Friendly Designs: There is a growing emphasis on designing power tools that are more ergonomic and user-friendly. Manufacturers are focusing on reducing tool weight, improving grip comfort, and minimizing vibration. These improvements aim to reduce user fatigue and increase precision, especially during prolonged use. Ergonomic designs are becoming a key differentiator in the competitive power tools market.

- Sustainable and Eco-Friendly Tools: As environmental concerns become more prominent, the demand for sustainable and eco-friendly power tools is rising. Manufacturers are exploring the use of recyclable materials, energy-efficient motors, and eco-friendly packaging. Additionally, there is an increased focus on reducing the carbon footprint of production processes and promoting the use of renewable energy sources in manufacturing.

- Enhanced Safety Features: Safety remains a paramount concern in the power tools industry. Recent developments include the integration of advanced safety features such as automatic shut-off, anti-kickback mechanisms, and improved blade guards. These features help prevent accidents and injuries, ensuring a safer working environment for users.

- Robotics and Automation: The incorporation of robotics and automation is transforming the way power tools are used in industrial applications. Robotic tools and automated systems are being deployed for tasks such as cutting, drilling, and assembly, enhancing precision and productivity. This trend is particularly evident in the construction and manufacturing sectors, where automation can significantly reduce labor costs and improve output quality.

- Increased Focus on Customization: Customization is becoming a key trend, with manufacturers offering tools that can be tailored to specific user needs. This includes interchangeable parts, adjustable settings, and modular designs that allow users to configure tools for various tasks. Customization enhances versatility and extends the lifespan of tools, providing better value for consumers.

- Expansion of DIY Market: The DIY (do-it-yourself) market is expanding, driven by increased home improvement activities and a growing interest in personal projects. Power tool manufacturers are targeting this segment with affordable, easy-to-use tools designed for non-professional users. The availability of online tutorials and DIY communities also supports this trend, making power tools more accessible to a broader audience.

Use Cases

- Concrete Drilling and Cutting: Power tools like hammer drills and rotary hammers are extensively used for drilling into concrete. For instance, the use of rotary hammers can reduce the time required to drill holes by 50% compared to manual methods.

- Woodworking: Circular saws, jigsaws, and planers are vital for cutting and shaping wood. These tools can achieve cuts at a rate of 5-10 meters per minute, significantly speeding up construction tasks.

- Assembly Line Operations: Impact wrenches and electric screwdrivers are commonly used for fastening and assembling automotive parts. The use of power tools in assembly lines can increase productivity by up to 30% and improve precision.

- Repair and Maintenance: Power tools such as angle grinders, polishers, and pneumatic tools are essential for vehicle repair and maintenance, reducing the time taken for tasks like grinding and polishing by up to 40%.

- Metal Fabrication: Angle grinders, metal saws, and drill presses are used for cutting, grinding, and drilling metal parts. The precision of these tools can reduce material wastage by approximately 20%, enhancing overall efficiency.

- Assembly Operations: Cordless drills and screwdrivers are used in the assembly of various products, allowing for flexible and mobile operations. These tools can cut assembly time by 25-35%, contributing to faster production cycles.

- DIY and Home Improvement: Furniture Making and Repair: Power tools such as electric sanders, drills, and saws are popular for DIY furniture projects. These tools can reduce project completion times by up to 60% compared to manual methods.

- Home Renovations: Tools like cordless drills, nail guns, and electric saws are used for tasks such as installing shelves, fixing cabinets, and building decks. Their use can increase the precision and safety of home improvement projects, reducing the risk of injury and errors.

- Aerospace Industry: Aircraft Maintenance: Power tools are used for tasks such as drilling, fastening, and sanding during aircraft maintenance and repairs. They enhance the precision of maintenance work, reducing downtime and improving aircraft safety and reliability.

- Component Manufacturing: Specialized power tools are used in the manufacturing of aerospace components, ensuring high precision and adherence to strict industry standards. This reduces defects and enhances the quality of the final products.

Oil and Gas Industry: - Pipeline Installation and Maintenance: Power tools like pipe cutters, drills, and grinders are essential for installing and maintaining pipelines. Their use ensures faster installation and maintenance, reducing project timelines by up to 25%.

Major Challenges

- High Maintenance Costs: Power tools, particularly those with moving parts, require regular maintenance to ensure optimal performance and longevity. The cost of maintaining these tools can be significant, leading to higher operational expenses for users. This challenge is especially pronounced in industrial settings where tools are used extensively.

- Fluctuating Raw Material Prices: The prices of raw materials such as steel, aluminum, and plastic, which are essential for manufacturing power tools, are subject to significant fluctuations. These price changes can impact production costs and profit margins for manufacturers. For instance, the volatility in metal prices due to global supply chain disruptions can lead to increased production costs and ultimately higher prices for consumers.

- Technological Integration and Complexity: As power tools become more advanced with the integration of smart technologies, the complexity of these tools increases. Users may face difficulties in adapting to new technologies, and the need for technical knowledge to operate advanced tools can be a barrier. Additionally, the initial cost of acquiring smart power tools can be high, limiting their accessibility to smaller businesses and individual consumers.

- Safety Concerns: Despite advancements in safety features, power tools still pose significant risks if not used properly. Accidents and injuries can occur due to improper handling, lack of training, or equipment malfunctions. Ensuring user safety requires ongoing education, strict adherence to safety protocols, and continuous improvement in tool design to minimize risks.

- Environmental Impact and Sustainability: The production and disposal of power tools raise environmental concerns. The manufacturing process involves the use of non-renewable resources and generates waste, contributing to environmental degradation. Moreover, the disposal of old and obsolete tools can lead to electronic waste. There is a growing need for sustainable practices in the production and recycling of power tools to mitigate their environmental impact.

Market Growth Opportunities

- Increased Adoption of Cordless Tools: The shift towards cordless power tools is one of the most prominent growth drivers. Advances in battery technology, particularly lithium-ion batteries, have resulted in tools that offer longer run times, quicker charging, and greater portability. This trend is particularly strong in the construction and DIY sectors, where flexibility and ease of use are critical. The cordless segment is anticipated to grow at a CAGR of over 5% during the next few years.

- Growth in the Construction Industry: The ongoing expansion of the construction industry, especially in emerging markets, presents substantial opportunities for the power tools market. Infrastructure development projects, urbanization, and the increase in residential and commercial construction are driving the demand for power tools. For instance, the construction sector in Asia-Pacific is expected to grow by over 6% annually, creating a robust market for power tools.

- Technological Advancements and Smart Tools: The integration of smart technology into power tools is another significant growth area. Features such as Bluetooth connectivity, IoT integration, and data analytics capabilities enhance tool efficiency and user experience. These innovations enable predictive maintenance, performance monitoring, and better inventory management. The smart tools segment is expected to see a growth rate of approximately 8% over the next decade.

- Expansion of the DIY Market: The rise in DIY activities, fueled by the increasing popularity of home improvement projects and the availability of online tutorials, is boosting the demand for power tools among hobbyists and non-professional users. This trend is particularly strong in North America and Europe, where the DIY culture is well-established. The DIY segment is projected to grow steadily, contributing significantly to the overall market expansion.

- Sustainability and Green Technologies: There is a growing emphasis on sustainability within the power tools industry. Manufacturers are increasingly focusing on developing eco-friendly tools, using recyclable materials, and adopting sustainable manufacturing practices. This shift not only addresses environmental concerns but also attracts environmentally conscious consumers, creating a new avenue for market growth. Sustainable tools are expected to capture a larger market share as regulatory pressures and consumer preferences shift towards green products.

Recent Developments

In 2023, Atlas Copco AB experienced a noteworthy year in the power tools sector, marked by record achievements and strategic advancements. The company reported revenues of SEK 173 billion and received record orders throughout the year. Significant milestones included the introduction of innovative power tools and assembly solutions that enhanced efficiency and precision in various industrial applications. For instance, in March 2023, the company expanded its product portfolio with new advancements in industrial power tools, focusing on user ergonomics and smart technology integration to meet growing market demands. Throughout the year, Atlas Copco also invested heavily in research and development, which is a key driver of their continuous innovation and market leadership. By the end of 2023, the company employed approximately 53,000 people globally, underscoring its expansive operational footprint and commitment to growth. This strategic focus on innovation and market expansion positions Atlas Copco AB strongly for sustained growth in 2024 and beyond.

Emerson Electric Co. has made significant strides in the power tools sector throughout 2023 and into 2024. In January 2023, Emerson reported a 5% increase in net sales compared to the previous quarter, reflecting the growing demand for their innovative power tools. By March, the company launched several new products, enhancing their portfolio with advanced features aimed at improving efficiency and user safety. In the same month, Emerson announced strategic partnerships to integrate smart technology into their tools, further driving market growth.

In May 2023, Emerson’s quarterly report highlighted a 10% increase in underlying sales, attributing this growth to the successful adoption of cordless power tools, which accounted for a significant portion of their revenue. During the summer, in July 2023, Emerson expanded its manufacturing capabilities to meet the rising demand, particularly in the construction and automotive sectors.

In 2023, Hilti Corporation demonstrated significant activity and growth in the power tools sector. Starting in January 2023, Hilti introduced several new products featuring enhanced ergonomic designs and advanced battery technology, which boosted their market presence. By March 2023, the company reported a 6% increase in sales, attributed to the successful launch of these innovative power tools. In May, Hilti expanded its global footprint by opening new distribution centers in key markets such as North America and Europe, aimed at improving delivery times and customer service.

Ingersoll-Rand plc has demonstrated robust activity in the power tools sector throughout 2023 and into early 2024. Starting in January 2023, the company launched an upgraded range of pneumatic and electric tools that emphasized efficiency and durability. This strategic move contributed to a notable 6% increase in power tools sales by March. By May 2023, Ingersoll-Rand introduced a new line of cordless power tools equipped with advanced lithium-ion batteries, enhancing performance and user convenience, which resulted in a 7% boost in sales for the second quarter.

Conclusion

The power tools market is experiencing dynamic growth, driven by technological advancements, increasing demand across various industries, and a shift towards more sustainable and efficient solutions. In 2023, the market showed a significant uptrend, with key players like Emerson Electric Co., Atlas Copco AB, Hilti Corporation, and Ingersoll-Rand plc making substantial strides in innovation and market expansion. The introduction of cordless and smart tools, along with improvements in battery technology and eco-friendly designs, has enhanced performance and user convenience, contributing to a robust increase in market revenues.