Table of Contents

Introduction

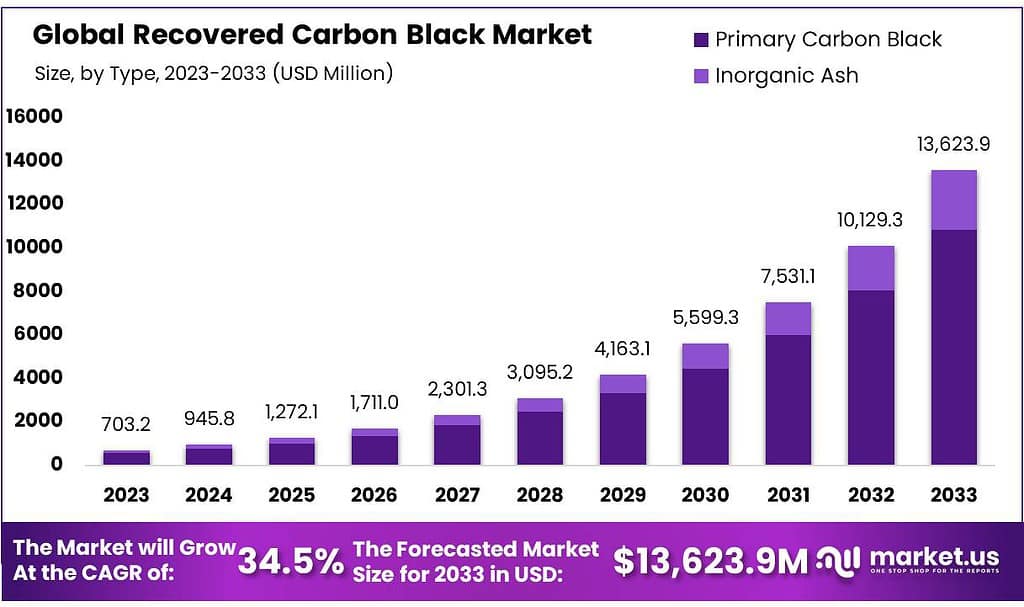

The recovered carbon black (rCB) market is poised for remarkable growth, with the market size projected to reach approximately USD 13,623 million by 2033, up from USD 703.2 million in 2023, reflecting a robust compound annual growth rate (CAGR) of 34.5% during the forecast period. This growth can be attributed to the increasing demand for sustainable materials in various industries, particularly in tire manufacturing and rubber products, where rCB is used as a substitute for traditional carbon black.

Additionally, regulatory pressures to reduce waste and enhance sustainability practices are driving investments in recycling technologies and processes. However, the market faces challenges such as limited awareness regarding the benefits of rCB compared to conventional carbon black and the initial high costs associated with the recycling process. Recent developments highlight significant technological advancements aimed at improving the efficiency of rCB production, further boosting its appeal.

Notably, companies are investing in innovative pyrolysis methods and facilities to enhance yield and quality, enabling them to meet the growing demand. As sustainability becomes a priority for manufacturers, the rCB market is set to play a crucial role in the transition toward circular economies. The convergence of regulatory support, technological advancements, and heightened awareness of environmental issues positions the recovered carbon black market for unprecedented growth in the coming decade, making it an attractive sector for investors and manufacturers alike.

Black Pellets Denmark ApS has also progressed by establishing a strategic partnership with local tire manufacturers, enhancing its supply chain for rCB production. This collaboration aims to streamline the recycling process and improve the quality of recovered materials, which is essential for applications in the automotive industry.

Bolder Industries has recently secured significant funding, raising over USD 20 million to expand its production facilities in North America. This investment will facilitate the scaling up of their pyrolysis technology, allowing them to produce larger volumes of high-quality rCB while decreasing environmental impact.

Blackwoods Protector has launched a new line of rCB products specifically designed for the rubber and plastics industries. This product launch aims to meet the growing market demand for eco-friendly alternatives, emphasizing sustainability and performance.

Key Takeaways

- In 2023, the global recovered carbon black market generated a revenue of USD 703.2 million, with a CAGR of 34.5%, and is expected to reach USD 13,623 million by the year 2033.

- The type held a major share of the market, with the primary carbon black segment taking the lead in 2023 with a market share of 79.7%.

- By grade, the commodity segment accounted for a significant share of 69.6%

- By form, the granular segment among the other sub-segments held a significant revenue share of the market with 66.5% of the global recovered carbon black market.

- By end-use, the transportation segment accounted for the dominant share of the 49.6%.

- The North American region led the market by securing a market share of 34.5% in 2023.

Recovered Carbon Black Statistics

- Grades with smaller particles, such as N110, N220, and N234, have high reinforcing, abrasion resistance, and tear strength. These grades are used as reinforcing filler materials to make rubber elastomers that form tread.

- Medium to high reinforcing grades like N330, N339, and N550 are found in treads, inner liners, carcasses, and sidewalls.

- Medium reinforcing vCB grades like N660 and N770 have low heat build-up and prevent tire deformation. They’re suitable for sidewalls, inner liners, and sealing rings.

- Low reinforcing vCBs with high loading capacity and elongation are suitable for inner liners and belts.

- The cumulative effect of vCBs makes tires safer and more durable for driving. There are 21.5 percent and 22 percent of vCBs in passenger and truck tires.

- Klean’s tire char upgrading systems enable the economic conversion of low-value tire char into high-value Carbon Black replacements which can replace virgin Carbon Black by volumes of 10% up to 100% depending on the applications.

- Carbon black is one of the darkest and most widely spread materials known. Chemically, carbon black is a colloidal form of elemental carbon consisting of 95 to 99% carbon.

- Manufacturing methods include furnace, gas, lamp, and thermal black processes. Above 98% of the world’s annual carbon black production is covered by the furnace black process.

- Carbon black typically contains more than 95% pure carbon with minimal quantities of oxygen, hydrogen, and nitrogen.

- The thermal black process accounts for less than 5 percent of vCB, while the lamp black process and the acetylene black process produce less than 2 percent of vCB.

- Over 90 percent of virgin carbon black finds its way into rubber products – mainly for tire-related products like tubes, treads, belts, and hoses.

Emerging Trends

- Sustainability Focus: There is a significant shift towards sustainable practices in manufacturing, driven by regulatory pressures and consumer demand for eco-friendly products. Companies are increasingly adopting rCB as a sustainable alternative to conventional carbon black, which aligns with global efforts to reduce waste and carbon emissions.

- Technological Advancements: Innovations in recycling technologies, particularly pyrolysis methods, are enhancing the efficiency and quality of rCB production. These advancements are leading to better yield rates and more consistent product characteristics, making rCB more attractive for various applications, including tires and plastics.

- Increased Demand from the Automotive Sector: The automotive industry is increasingly incorporating rCB into tire manufacturing and other rubber components. This demand is driven by the need for lightweight materials that contribute to fuel efficiency and reduce environmental impact.

- Circular Economy Initiatives: Many companies are embracing circular economy principles, which emphasize recycling and reusing materials. This trend is fostering collaborations between manufacturers and recyclers to create closed-loop systems that maximize resource efficiency.

- Growing Awareness and Acceptance: As awareness of the benefits of rCB grows, more manufacturers are willing to invest in it. Educational campaigns and industry partnerships are helping to bridge the knowledge gap regarding the performance and sustainability of rCB compared to traditional carbon black.

Use Cases

- Tire Manufacturing: The automotive industry is one of the largest consumers of rCB, with approximately 70% of rCB production used in tires. rCB serves as a key reinforcing agent, enhancing tire performance by improving durability and reducing rolling resistance, which can lead to better fuel efficiency.

- Rubber Products: Beyond tires, rCB is utilized in various rubber applications, such as conveyor belts, seals, and gaskets. These products benefit from rCB’s properties, which enhance strength and longevity while providing a sustainable alternative to traditional carbon black.

- Plastics: rCB is increasingly used in plastic manufacturing, especially in composite materials. By integrating rCB into plastics, manufacturers can improve mechanical properties and contribute to a circular economy. Studies indicate that using rCB in plastic applications can reduce the carbon footprint by up to 30%.

- Coatings and Inks: rCB is also being incorporated into paints, coatings, and inks. Its use not only improves color and opacity but also adds environmental value, making these products more attractive to eco-conscious consumers.

- Construction Materials: The construction industry is exploring rCB for use in asphalt and concrete. Incorporating rCB can enhance the mechanical properties of these materials while also supporting sustainability initiatives, contributing to reduced waste in landfills.

Major Challenges

- Quality Consistency: One of the primary challenges is the inconsistency in the quality of rCB produced from different sources. Variations in the feedstock used, such as end-of-life tires, can lead to differences in properties like strength and purity. This inconsistency can deter manufacturers from fully integrating rCB into their products.

- High Production Costs: The initial costs associated with rCB production can be high, primarily due to the advanced technologies required for recycling and processing. This can make rCB less competitive compared to traditional carbon black, particularly for smaller manufacturers.

- Limited Awareness: Many potential users remain unaware of the benefits and applications of rCB. Educational initiatives are necessary to inform stakeholders in various industries about the advantages of switching to rCB, but these efforts require time and investment.

- Regulatory Barriers: The rCB industry is subject to stringent regulations regarding the recycling processes and the safety of the materials used. Navigating these regulations can be complex and may hinder market entry for new players or innovations.

- Market Acceptance: Despite the environmental benefits, some manufacturers remain hesitant to adopt rCB due to concerns about performance compared to traditional carbon black. This reluctance can slow the transition to more sustainable materials, impacting market growth.

Market Growth Opportunities

- Increasing Demand for Sustainable Materials: As industries become more focused on sustainability, the demand for eco-friendly materials like rCB is growing. The global emphasis on reducing carbon footprints positions rCB as an attractive alternative to traditional carbon black, particularly in sectors like tire manufacturing, which accounts for about 70% of rCB usage.

- Expansion in Automotive Applications: The automotive industry is increasingly adopting rCB in tire production and other rubber components. With the global tire market expected to reach USD 320 billion by 2026, the integration of rCB could significantly increase, contributing to market growth.

- Technological Advancements: Innovations in recycling technologies are improving the efficiency and cost-effectiveness of rCB production. For instance, advanced pyrolysis methods can enhance yield and quality, enabling companies to produce higher quantities of rCB at lower costs.

- Government Initiatives and Regulations: Many governments are implementing regulations that promote recycling and sustainability. These initiatives encourage manufacturers to incorporate rCB into their products, fostering market growth. For example, policies aimed at reducing landfill waste and increasing recycling rates can create favorable conditions for rCB adoption.

- Emerging Applications: New applications for rCB are continually being explored, including its use in coatings, plastics, and construction materials. The diversification of applications can expand the market reach and increase demand across different industries.

Key Player Analysis

Black Bear Carbon B.V. is a prominent player in the recovered carbon black sector, specializing in the sustainable recycling of end-of-life tires into high-quality carbon black. Utilizing an innovative patented process, the company converts waste tires into valuable materials, contributing to the circular economy. Black Bear Carbon focuses on producing rCB that meets industry standards, enabling its use in tire manufacturing and other rubber products. Their commitment to sustainability and technological advancement positions them as a leader in promoting environmentally friendly practices in the carbon black market.

Hostess Brands, LLC is primarily known for its baked goods, but the company is also exploring sustainable practices in its operations, including the utilization of recovered carbon black in packaging materials. By integrating rCB into its products, Hostess aims to enhance the environmental profile of its packaging while maintaining product quality. This initiative reflects the company’s broader commitment to sustainability and reducing its carbon footprint, aligning with consumer demands for eco-friendly practices. Through these efforts, Hostess Brands is contributing to the growth of the rCB market and promoting a circular economy.

Blackwoods Protector is involved in the recovered carbon black sector by focusing on the development of innovative materials that incorporate rCB into various products, enhancing their sustainability. By utilizing recovered carbon black in their formulations, Blackwoods aims to reduce waste while improving the performance of their products, particularly in applications like coatings and rubber goods. Their commitment to eco-friendly practices not only supports the circular economy but also aligns with growing consumer demand for sustainable solutions in industrial applications.

Bolder Industries is a key player in the recovered carbon black market, specializing in the production of high-quality rCB from end-of-life tires. The company utilizes advanced pyrolysis technology to convert waste tires into valuable carbon black, which can be used in tire manufacturing, plastics, and other rubber products. Bolder Industries emphasizes sustainability and aims to significantly reduce the carbon footprint associated with traditional carbon black production. Their innovative approach positions them as a leader in the transition toward more sustainable materials in various industries.

Cabot Corporation is a leading player in the recovered carbon black sector, focusing on sustainable solutions for the rubber and plastics industries. The company has developed advanced technologies to produce high-quality rCB from end-of-life tires, allowing it to meet the growing demand for eco-friendly materials. Cabot’s commitment to innovation and sustainability not only enhances the performance of its products but also supports environmental goals by reducing waste and lowering carbon emissions associated with traditional carbon black production.

Carbon Clean Tech AG specializes in the recovery of carbon black through innovative recycling processes. The company utilizes advanced pyrolysis technology to convert waste tires into valuable carbon black, which can be used in various applications, including tire manufacturing and rubber products. By focusing on sustainability and resource efficiency, Carbon Clean Tech AG aims to contribute significantly to the circular economy. Their efforts in producing high-quality recovered carbon black position them as a key player in promoting eco-friendly practices within the industry.

Carbon Recovery GmbH is focused on the recovery of carbon black through innovative recycling processes. The company specializes in converting end-of-life tires into high-quality recovered carbon black, contributing to sustainability and reducing waste in landfills. Their advanced technologies enhance the efficiency of carbon recovery, allowing for better quality and performance of the rCB produced. By promoting eco-friendly practices, Carbon Recovery GmbH is positioned as a significant player in the growing market for sustainable materials, supporting industries seeking greener alternatives.

Continental Carbon Company is a prominent entity in the recovered carbon black sector, known for its innovative production methods. The company employs advanced technologies to recycle waste tires into valuable carbon black, making significant strides in sustainability. Their patented processes focus on improving the quality and performance of rCB, which is essential for applications in the rubber and plastics industries. By prioritizing eco-friendly practices and resource efficiency, Continental Carbon Company aims to lead the transition towards a more sustainable manufacturing landscape.

Delta Techniks GmbH specializes in the production of recovered carbon black (rCB) through advanced recycling technologies. The company focuses on converting waste materials, particularly used tires, into high-quality rCB that meets industry standards. By employing innovative processes, Delta Techniks aims to enhance the sustainability of its products while reducing environmental impact. Their commitment to eco-friendly practices positions them as a valuable contributor to the rCB market, supporting industries looking for sustainable material alternatives.

Delta-Energy Group, LLC is a key player in the recovered carbon black sector, known for its effective recycling methods that transform waste tires into valuable carbon black. The company utilizes proprietary technologies to ensure high-quality output, catering to the increasing demand for sustainable materials in various industries, including automotive and manufacturing. By focusing on resource recovery and sustainability, Delta-Energy Group not only contributes to reducing waste but also helps businesses meet their environmental goals, promoting a circular economy.

Dharmapuri Carbon Black Pvt Ltd. focuses on producing recovered carbon black (rCB) from waste tires, contributing significantly to sustainability in the rubber industry. Utilizing advanced recycling technologies, the company converts end-of-life tires into high-quality rCB, which can be used in various applications, including tire manufacturing and industrial rubber products. Their commitment to eco-friendly practices not only helps reduce landfill waste but also supports industries seeking sustainable alternatives, positioning Dharmapuri as a key player in the growing rCB market.

Dron Industries Ltd. is engaged in the production of recovered carbon black, specializing in innovative recycling methods that convert used tires into valuable carbon black products. The company emphasizes high-quality output and compliance with industry standards, making its rCB suitable for various applications in the automotive and rubber sectors. By focusing on sustainability and resource recovery, Dron Industries aims to meet the increasing demand for eco-friendly materials while promoting environmental stewardship, thus enhancing its position in the recovered carbon black market.

Pyrolyx AG is a leading company in the recovered carbon black sector, specializing in the recycling of end-of-life tires into high-quality carbon black. Utilizing advanced pyrolysis technology, Pyrolyx efficiently transforms waste materials into valuable products, significantly reducing environmental impact. Their commitment to sustainability aligns with the growing demand for eco-friendly materials in various industries, including automotive and rubber manufacturing. By providing a reliable source of recovered carbon black, Pyrolyx AG plays a crucial role in promoting a circular economy and enhancing material sustainability.

Radhe Group of Energy is actively involved in the recovered carbon black market, focusing on sustainable energy solutions and the recycling of waste materials. The company employs innovative processes to convert waste tires into valuable recovered carbon black, which can be used in various applications, such as tire production and industrial rubber goods. Radhe Group’s commitment to environmental stewardship and resource recovery supports its mission to provide eco-friendly alternatives while meeting the increasing demand for sustainable materials in the market.

Hosokawa Micron B.V. is a key player in the recovered carbon black sector, focusing on advanced processing technologies that enable the efficient recovery and refinement of carbon black from waste materials. The company provides innovative solutions for the recycling industry, ensuring high-quality output that meets stringent industry standards. By integrating sustainable practices into its operations, Hosokawa Micron supports the transition towards eco-friendly materials, making significant contributions to the circular economy and enhancing the overall sustainability of the carbon black market.

Klean Industries Inc. specializes in sustainable recycling solutions, including the production of recovered carbon black from end-of-life tires. Utilizing advanced pyrolysis technology, Klean Industries efficiently transforms waste tires into high-quality carbon black, which can be utilized in various applications such as rubber manufacturing and coatings. The company emphasizes environmental responsibility and resource recovery, aligning with the growing demand for eco-friendly materials. Through its innovative approaches, Klean Industries plays a vital role in promoting sustainability within the carbon black sector.

Conclusion

The recovered carbon black (rCB) market is on a trajectory of significant growth, driven by increasing demand for sustainable materials, technological advancements, and expanding applications across various industries. With projections indicating the market could reach approximately USD 13,623 million by 2033, stakeholders are recognizing the potential of rCB as a viable alternative to traditional carbon black.

However, challenges such as quality consistency and market acceptance must be addressed to fully realize this potential. By focusing on innovation, regulatory support, and education, the rCB industry can capitalize on emerging opportunities, contributing to a more sustainable and circular economy. The outlook for rCB remains positive, positioning it as a crucial component in the future of manufacturing and environmental stewardship.