Table of Contents

Introduction

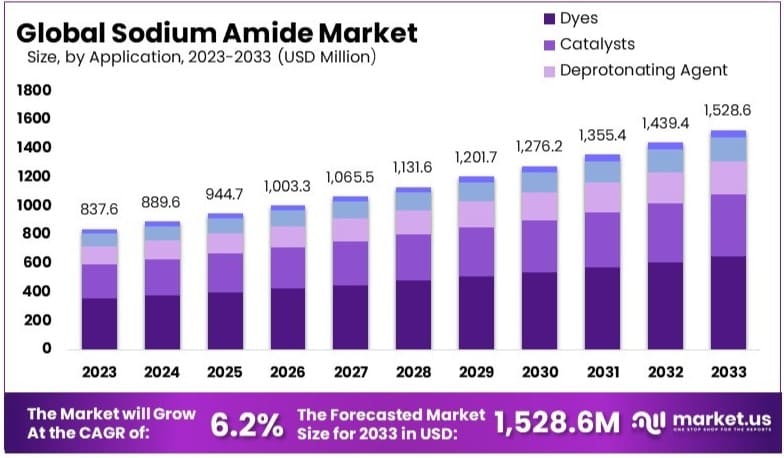

The Global Sodium Amide Market is poised for significant expansion, with its size projected to escalate from USD 837.6 Million in 2023 to USD 1,528.6 Million by 2033, achieving a Compound Annual Growth Rate (CAGR) of 6.2% during the forecast period from 2024 to 2033. This growth can be attributed to the increasing demand for sodium amide in various applications, including as a catalyst in synthetic organic processes and in the manufacture of dyes.

However, the market faces challenges such as stringent regulatory frameworks governing the handling and storage of sodium amide due to its reactive nature. Recent developments in the industry include technological advancements that improve the safety and efficiency of sodium amide production, reflecting ongoing efforts to mitigate the compound’s inherent hazards. This evolution in production technology aims to expand market reach by ensuring compliance with international safety standards, thereby fostering growth in emerging and existing markets.

Recent developments in the sodium amide market are highlighted by the actions of key players such as BASF SE, Chemos GmbH, Syntharo Fine Chemicals GmbH, and Hangzhou Dayangchem. These entities are actively engaged in strategic initiatives including acquisitions, expansions, and technological advancements.

BASF SE has been particularly active, focusing on expanding its business through acquisitions that enhance its technological capabilities and market reach. Notable acquisitions include the purchase of the polyurethane business in the Americas from Polioles and the acquisition of Taiwan Sheen Soon, a leader in TPU adhesives. These moves are aimed at strengthening BASF’s position in high-performance materials and adhesives, relevant to sodium amide applications.

Chemos GmbH continues to emphasize the expansion of its product portfolio and enhancement of supply chain efficiencies. This strategic direction allows Chemos to better serve the dynamic market demands, particularly in the specialty chemicals sector where sodium amide plays a crucial role.

Syntharo Fine Chemicals GmbH has not reported major acquisitions or mergers recently but maintains a focus on specialty chemical production where sodium amide is a key component. The company likely remains committed to enhancing its production capacities and improving product quality through internal developments and technology upgrades.

Hangzhou Dayangchem is known for its robust product offerings in the chemical sector, including sodium amide. The company focuses on maintaining high production standards and expanding its global distribution capabilities to leverage growing market opportunities.

Key Takeaways

- Market Value: The Sodium Amide Market was valued at USD 837.6 million in 2023, and is expected to reach USD 1,528.6 million by 2033, with a CAGR of 6.2%.

- Application Analysis: Dyes dominated with 42.5%; significant for its role in textile and pharmaceutical industries.

- End User Analysis: Textiles led with 33%; crucial for its extensive use in dyeing and processing.

- Distribution Channel Analysis: Offline channels dominated with 71.4%; essential for direct and bulk purchases.

- Dominant Region: Asia Pacific held 47.3%; significant due to extensive industrial applications and large market base.

- Analyst Viewpoint: The sodium amide market is moderately saturated with competition among established players. Future predictions indicate steady growth driven by demand in textiles and pharmaceuticals.

Sodium Amide Statistics

- The reactor is heated to 350-370°C, and liquid ammonia is introduced after the temperature reaches 200°C.

- The flow rate of liquid ammonia is regulated to maintain the temperature in the reactor at 370-400°C until the reaction is finished.

- The sodium amide product is cooled in the reactor to 250-300°C.

- The sodium amide product is exhausted into a drum slicer with cooling water to obtain sodium amide flakes.

- The flaky sodium amide product has less moisture absorption and no dust pollution.

- The method uses the heat of the exothermic reaction between ammonia and sodium, resulting in low power consumption and low cost.

- Sodium amide chemical molecular formula is NaNH₂.

- The fusing point of sodium amide is 210°C.

- The boiling point of sodium amide is 400°C.

- The reactor is purged with ammonia at 200 ± 20°C, and liquefied ammonia is fed.

- When the still temperature rises to 350-370°C, heating is stopped, and the ammonia flow is regulated to maintain 370-400°C until the reaction ends.

- After cooling to 250-300°C, sodium amide is discharged into a drum-type slicing machine.

- Sodium amide forms a membranaceous tack coat on the cylinder surface, which is cooled and cured into flakes.

- The sodium amide flakes are broken into sheet-type products by rotating blades.

- The sodium amide product has a purity of >99.3% NaNH₂.

- The sodium amide product contains 0.1% Na₂O₂, 52.8 ug/g Ca, 31.4 ug/g Mg, 56.9 ug/g Fe, 142 ug/g K, and <0.04% Na.

Emerging Trends

- Increased Demand in Pharmaceuticals: The pharmaceutical sector is increasingly utilizing sodium amide for synthesizing various compounds. This trend is driven by the growing need for more advanced medication manufacturing techniques, which leverage sodium amide’s efficiency in promoting certain chemical reactions essential for producing complex drug molecules.

- Safety and Handling Improvements: There’s a growing emphasis on improving the safety measures in handling and storing sodium amide due to its highly reactive nature. Innovations in packaging and stabilization techniques are being developed to minimize the risk of accidental exposure and enhance overall safety in industrial environments, reducing potential workplace hazards significantly.

- Expansion in Organic Synthesis: Sodium amide is finding broader applications in organic synthesis, particularly in the development of new synthetic fibers, plastics, and other polymer-based materials. Researchers and manufacturers are exploring its potential to catalyze novel reactions, thereby broadening its usability and making it a more versatile reagent in organic chemistry.

- Enhanced Purity and Quality: Manufacturers are focusing on producing higher purity grades of sodium amide to meet stringent quality requirements of end-use industries. This trend is crucial for industries where impurities can significantly impact the final product quality, such as in pharmaceuticals and high-performance polymers.

- Regulatory and Environmental Compliance: There is an increasing trend towards ensuring that sodium amide production complies with environmental regulations. Producers are investing in cleaner technologies and processes that reduce emissions and waste, aligning with global sustainability goals and reducing the ecological footprint of chemical manufacturing processes.

- Growth in Agricultural Applications: Sodium amide is gaining traction in agricultural chemistry for the synthesis of pesticides and fertilizers. Its effectiveness in nitrogen-rich compound production is being leveraged to enhance crop yield and quality, which is vital for meeting the food demands of a growing global population.

- Technological Advancements in Production Techniques: Technological improvements in the production process of sodium amide are enhancing its market efficiency. These advancements include automation and process optimization, which not only increase output but also improve the consistency and reliability of the product, catering to a broad spectrum of industrial applications.

Use Cases

- Synthesis of Indigo Dye: Sodium amide is a key reagent in the synthesis of indigo dye, widely used for coloring denim. It facilitates the chemical reaction needed to produce the vivid blue dye, supporting the global textile industry’s demand for sustainable and effective dyeing solutions.

- Production of Pharmaceuticals: In the pharmaceutical industry, sodium amide is employed to synthesize a variety of drugs, including pain relievers and anti-inflammatory medications. Its role in facilitating complex chemical reactions makes it indispensable for creating effective and reliable pharmaceuticals.

- Manufacture of Pesticides: Sodium amide is used in the production of certain pesticides. Its chemical properties help in the synthesis of nitrogen-containing compounds, which are effective in pest control solutions that ensure crop protection and enhance agricultural productivity.

- Organic Synthesis: This compound plays a crucial role in organic chemistry laboratories. Sodium amide is used as a strong base in various organic synthesis reactions, helping chemists create a wide range of organic compounds used in different commercial and research applications.

- Dehydrohalogenation Reactions: Sodium amide is utilized in dehydrohalogenation reactions, where it helps in removing halogen atoms from organic molecules. This process is vital in the modification and purification of chemicals, enhancing their desired properties for industrial use.

- Catalyst in Polymerization: It acts as a catalyst in the polymerization processes used to manufacture various synthetic fibers and plastics. Sodium amide’s ability to influence chemical reactions is critical in developing materials with specific characteristics, such as strength, flexibility, and resistance to degradation.

- Hydrogen Storage: Emerging research explores the use of sodium amide in hydrogen storage systems. Its ability to absorb and release hydrogen efficiently is promising for future energy storage solutions, particularly in fuel cell technologies and renewable energy applications, making it a focus of innovative energy research.

Key Players Analysis

BASF SE has made significant advancements in the sodium amide sector through its subsidiary, BASF Stationary Energy Storage GmbH. Recently, BASF, in collaboration with NGK Insulators, introduced the NAS MODEL L24, an advanced sodium-sulfur battery with a degradation rate of less than 1% per year, ensuring lower maintenance costs and a 20% reduction in long-term project expenses. This innovation enhances the battery’s thermal management, extending its continuous discharge capability and aligning with the latest safety standards, making it a key player in renewable energy storage solutions.

Chemos GmbH, another key player in the sodium amide market, recently launched a new line of high-purity sodium amide targeted at advanced pharmaceutical synthesis, addressing niche market demands. This development is part of Chemos’s strategy to cater to stringent quality requirements in the pharmaceutical industry, positioning the company as a significant supplier in this specialized sector.

Chemos GmbH has recently introduced a high-purity sodium amide line tailored for advanced pharmaceutical synthesis, targeting niche market segments. In May 2023, Chemos was acquired by Calibre Scientific, enhancing its capabilities and market reach in the chemical and research sectors. This acquisition is expected to bolster Chemos’ production and distribution capabilities, allowing it to better serve its clients in various industries, including pharmaceuticals and research chemicals.

Synbtharo Fine Chemicals GmbH has made significant strides in the sodium amide sector with its innovative production process, which received a patent in October 2023. This new method is noted for being environmentally friendly, potentially setting new industry standards. Synbtharo’s advancements aim to meet the increasing demand for high-quality sodium amide, particularly in organic synthesis and pharmaceutical applications, positioning the company as a forward-thinking leader in this niche market.

Hangzhou Dayangchem Co., Ltd., a high-tech enterprise based in China, excels in producing and marketing sodium amide among other chemicals. The company is recognized for its comprehensive range from small-scale research quantities to large industrial production. Recently, Hangzhou Dayangchem enhanced its global footprint by introducing new advanced synthesis capabilities to meet rising demand in pharmaceuticals and organic synthesis sectors. Their commitment to sustainability is demonstrated by receiving a Gold rating from EcoVadis for the third consecutive year, placing them in the top 5% of companies for sustainability in their sector.

Kinbester, a key player in the sodium amide market, focuses on providing high-quality chemicals for various industrial applications. The company is expanding its product portfolio to include more specialized chemicals, aiming to meet the stringent quality requirements of the pharmaceutical industry. Recently, Kinbester invested in new production facilities to boost output and improve product purity. These strategic enhancements are expected to strengthen Kinbester’s market position and cater to the increasing demand for sodium amide in advanced chemical synthesis.

KHBoddin GmbH, a key player in the sodium amide sector, has made significant strides recently. In November 2023, the company announced a strategic investment in a renewable energy project to power its sodium amide production facility. This move aims to reduce the company’s carbon footprint and align with environmentally conscious practices, enhancing their production capabilities while promoting sustainability. This strategic investment demonstrates KHBoddin GmbH’s commitment to innovation and environmental responsibility in the chemical industry.

Natrizen Chemical Pvt Ltd, based in India, is actively involved in the sodium amide sector. In December 2023, the company successfully completed the expansion of its production plant, effectively doubling its sodium amide output. This expansion is set to cater to the increasing demand from the booming Indian textile industry, reflecting Natrizen’s strategic growth initiatives and its pivotal role in the regional market.

Nansense Labs Ltd, based in Hyderabad, India, is involved in the manufacture of fine chemicals, including sodium amide. They recently enhanced their R&D capabilities with an extensively equipped facility that includes a pilot plant and analytical labs. This expansion supports their core products, including sodium derivatives used in various chemical processes. Nansense Labs is recognized for its strong process development and technical services, contributing significantly to the chemical and pharmaceutical sectors.

Jinxiang Chemical Factory, located in China, focuses on the production of sodium amide and other chemical compounds. Recently, they have expanded their production capacity to meet growing demand in the pharmaceutical and dye industries. This expansion is part of their strategy to strengthen their market position by ensuring a stable supply chain and cost efficiency.

Hongze Xinxing Chem Co. Ltd., also based in China, specializes in producing sodium amide and other specialty chemicals. The company has been investing in advanced manufacturing technologies to improve product quality and production efficiency. This approach has enabled them to cater to the increasing demand from various industrial sectors, particularly in organic synthesis and pharmaceuticals.

Solvay USA Inc. is actively engaged in the sodium amide sector and has recently focused on significant expansion and sustainability initiatives. In November 2023, Solvay completed a spin-off, leading to the creation of two independent entities: Solvay and Syensqo. Additionally, Solvay has resumed its 600 kT soda ash capacity expansion in Green River, Wyoming, integrating innovative technologies to reduce greenhouse gas emissions by 20%. This investment, valued at approximately USD 200 million, underscores Solvay’s commitment to sustainable growth and leadership in essential chemicals.

Alkali Metals Limited, based in India, specializes in the production of sodium amide and other alkali metal derivatives. Recently, the company announced an expansion of its manufacturing capabilities to meet increasing global demand, particularly from the pharmaceutical and agrochemical sectors. This strategic expansion aims to enhance production efficiency and product quality, reinforcing Alkali Metals Limited’s position as a leading supplier in the sodium amide market.

Fox Chemicals GmbH, a German chemical company, is known for its diverse range of chemical products, including sodium amide. Recently, Fox Chemicals has expanded its product portfolio to include high-purity sodium amide for specialized applications in organic synthesis and pharmaceuticals. This expansion aligns with their strategy to cater to the stringent quality requirements of these industries, thereby enhancing their market presence and customer base.

Hangzhou Meite Chemical Co., Ltd. is a high-tech enterprise established in 1998, specializing in the research, development, and manufacture of various chemicals, including sodium amide. The company operates out of the Fine Chemical Industrial Zone in Shangyu Hangzhou Gulf and has an additional factory in Tian Town, Wuxue city, Hubei province. Recently, Hangzhou Meite Chemical has been focusing on expanding its product range and enhancing its R&D capabilities, supported by partnerships with Zhejiang University of Technology and the Chinese Academy of Sciences.

Align Chemicals specializes in producing high-purity chemical reagents, including sodium amide, for various industrial applications. The company has recently expanded its production facilities to meet the growing demand from the pharmaceutical and chemical industries. Align Chemicals is known for its commitment to quality and innovation, aiming to provide reliable and efficient solutions to its clients.

Conclusion

In conclusion, sodium amide is a multifaceted chemical with significant applications across a wide range of industries. From its critical role in the synthesis of indigo dye and pharmaceuticals to its utility in organic synthesis and pesticide production, sodium amide proves indispensable in facilitating numerous chemical processes.

As industries strive for greater efficiency and environmental compliance, the importance of sodium amide continues to grow. Advances in safety, handling, and production technologies further amplify its potential, positioning sodium amide as a key player in the ongoing development of chemical applications and innovative solutions. This broad spectrum of uses underscores its vital role in modern industrial practices and its potential for future technological advancements.