Table of Contents

Introduction

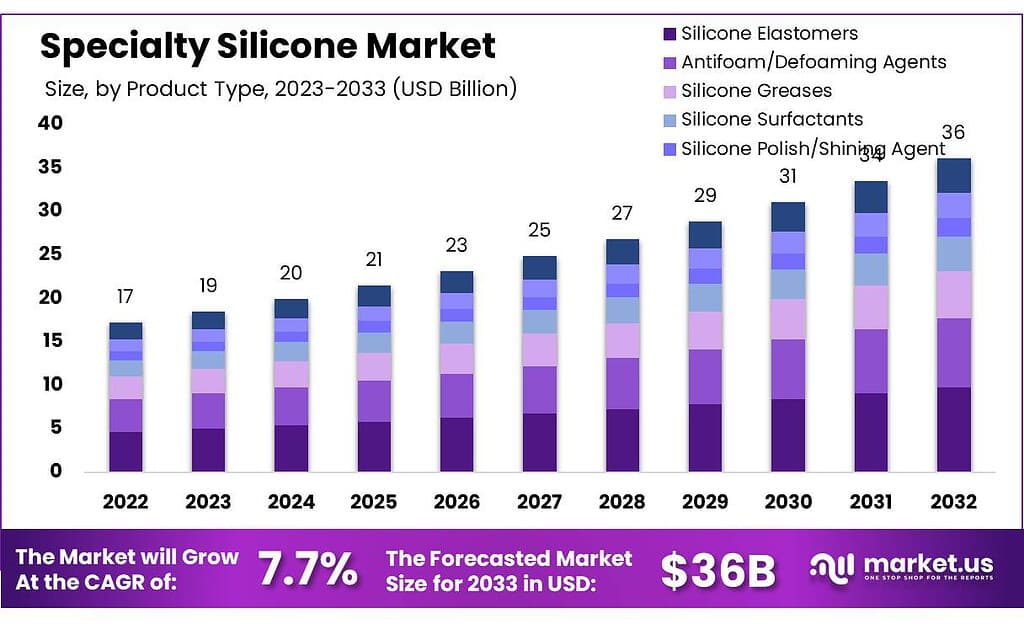

The global Specialty Silicone Market is poised for significant growth, projected to expand from USD 17 billion in 2023 to approximately USD 36 billion by 2033, demonstrating a robust compound annual growth rate (CAGR) of 7.7%. This market’s evolution is primarily driven by its diverse applications across various sectors such as automotive, healthcare, electronics, and construction, which demand materials that provide durability and performance under extreme conditions.

Several challenges do impact this market’s trajectory. The volatility in raw material prices and stringent regulatory policies can pose hurdles. However, ongoing technological innovations and the development of high-performance specialty silicones are creating new opportunities. Recent advancements include the introduction of bio-based and eco-friendly silicone solutions, reflecting a shift towards more sustainable practices.

Recent developments in the market underscore the dynamic nature of the specialty silicone industry. For instance, in 2024, companies like Elkem ASA and Shin-Etsu Chemical Co. have introduced innovations such as bio-based performance silicones and water-based silicone resins that enhance both environmental compatibility and functional performance. Additionally, substantial investments like Wacker Chemie AG’s expansion of manufacturing capacities in China, which amounted to around USD 158.73 million, highlight the strategic focus on scaling production to meet global demand.

This growth is further supported by the expanding applications of silicones in medical devices, automotive components, and personal care products, where their unique properties such as biocompatibility, durability, and thermal stability are highly valued. The market’s expansion is particularly notable in regions like Asia Pacific, driven by industrial growth and urbanization, which fuels the demand for construction-related silicone products.

The Bellofram Group of Companies, renowned for their engineering and manufacturing expertise in polymers and elastomers, continues to focus on tailored solutions that meet the specific needs of the infrastructure and automotive industries, emphasizing their role in high-performance applications. Chemsil Silicones Inc. stands out in the cosmetics and personal care sectors, offering innovative silicone-based solutions that enhance product performance and consumer satisfaction. Their dedication to providing specialized silicone formulations underlines their strong position in these markets.

CHT Germany GmbH, on the other hand, has been actively expanding its silicone portfolio to cater to a broader range of industries, including textiles, automotive, and healthcare. Their focus on quality and versatile silicone applications demonstrates their commitment to meeting the evolving demands of the global market.

Key Takeaways

- The global specialty silicone market is projected to grow from USD 17 billion in 2023 to USD 36 billion by 2033, at a CAGR of 7.7%.

- In 2023, silicone elastomers led with a 27.4% market share, used extensively in automotive, aerospace, and healthcare applications.

- Silicone fluids dominated with a 44.3% share in 2023, valued for their versatility in lubrication and thermal management.

- Molded parts held a 25.3% market share in 2023, crucial for customized components in healthcare and other industries.

- Asia Pacific accounted for 39.5% of the market in 2023, valued at USD 6.7 billion, driven by industrial and construction demand.

- Specialty silicones captured a 21.4% market share in 2023, valued for their durability and heat resistance in-vehicle components.

Specialty Silicone Statistics

- Silicone oven mitts are able to withstand temperatures up to 260 °C (500 °F), making it possible to reach into boiling water.

- Our expertise in specialized organo-modified silicone polymers has resulted in more than 40 patents.

- These materials are the chemical combination of the silicone polymer with styrene or aliphatic alpha-olefins and are available from two to 32 carbon chain lengths.

- We can manufacture these commercially from 20 kg to 20 tons and routinely develop new Silsurf structures for specific customer needs.

- Trade in Silicone represent 0.045% of total world trade.

- In 2022 the top exporters of Silicone were China ($2.2B), Germany ($2.07B), United States ($1.55B), Japan ($1.01B), and United Kingdom ($612M).

- In 2022, market concentration measured using Shannon Entropy, was 3.65. This means that most of the exports of Silicone are explained by 12 countries.

- This is done by heating large volumes of quartz sand to extremely high temperatures, often up to 1800 °C.

- A C–C backbone unit has a bond length of 1.54 Å and a bond angle of 112°, whereas an Si–O backbone unit has a bond length of 1.63 Å and a bond angle of 130°.

- The difference in total charge and mass between carbon with 6 protons and 6 neutrons, and silicon with 14 protons and 14 neutrons causes an added layer of electrons and their screening effect changes the electronegativity between the two elements.

- Silicone-insulated cables are advantageous in that they can withstand temperatures from -90°C to 200°C, and are highly flexible.

Emerging Trends

- The specialty silicone market is experiencing several emerging trends that are shaping its future trajectory. These trends reflect both the evolving technological landscape and the shifting demands of various industries that rely on silicone products.

- One significant trend is the increasing adoption of bio-based and sustainable production methods. Companies are focusing on developing eco-friendly silicone variants to reduce environmental impact and comply with stringent regulatory standards. This shift is also driven by consumer preference for more sustainable materials.

- Another trend is the use of silicone in high-performance applications, particularly in the electronics and automotive sectors. For example, silicones are being employed in electric vehicles for battery encapsulation and thermal management, enhancing both performance and safety. Additionally, the demand for silicone in medical applications continues to grow due to its biocompatibility, which is crucial for medical implants and devices

- The market is also seeing innovations such as the integration of silicone with nanotechnology to create products with enhanced properties like improved conductivity and mechanical strength. Such advancements are making silicone suitable for a wider range of applications, from conductive inks to high-performance adhesives and sealants.

- Moreover, the specialty silicone market is expanding its footprint in personal care products. Silicone surfactants and emollients are being extensively used to improve the texture and efficacy of skincare and haircare products, making them more appealing to consumers.

Use Cases

- Healthcare and Medical Devices: Specialty silicone is extensively used in the healthcare sector for medical implants and devices due to its biocompatibility. It is also utilized in making tubing, seals, and gaskets for medical equipment, offering durability and sterility.

- Electronics: In the electronics industry, silicone serves as an excellent material for encapsulants and sealants due to its thermal and electrical insulation properties. It’s used in various components such as sensors, connectors, and switches to protect them from moisture and mechanical stress.

- Automotive: Silicone finds significant use in the automotive industry, particularly in high-temperature applications such as under-hood components. It is used for making gaskets, hoses, and seals that must perform reliably in harsh conditions.

- Construction: Due to its weather-resistant properties, silicone is a preferred material for sealants and adhesives in the construction industry. It helps in providing longevity and durability to building materials against moisture and temperature variations.

- Aerospace: Specialty silicone is crucial in aerospace applications for bonding and sealing components. It is also used in coatings to protect aircraft parts from extreme environmental conditions encountered during flight.

- Personal Care: In the beauty and personal care industries, silicone enhances the texture and application properties of cosmetics and skincare products. It provides a smooth, silky feel and improves the spreadability of creams and lotions.

Major Challenges

- The specialty silicone market faces several significant challenges that could impact its growth trajectory. One of the primary challenges is the volatility in raw material prices. This volatility can directly affect production costs, leading to increased prices for silicone products and potentially shrinking profit margins for manufacturers. For instance, the fluctuating costs of key raw materials like methyl chloride and silicon metal have been a persistent issue, impacting manufacturers’ ability to maintain stable pricing.

- Another major challenge is regulatory scrutiny, particularly concerning the environmental and health impacts of silicones. Specialty silicones, while advantageous due to their durability and performance in extreme conditions, have come under scrutiny for their potential harmful effects on human skin. This has led to tighter regulations that could limit the use of certain types of silicones, especially in consumer products and industries like personal care, where direct skin contact is frequent.

- Additionally, the market dynamics are influenced by the need for continuous innovation to meet the evolving demands of various industries such as automotive, electronics, and healthcare. Companies must invest in research and development to create new silicone formulations that are not only effective but also comply with increasingly stringent environmental and safety standards.

Market Growth Opportunities

- Aerospace and Defense Applications: The market is witnessing a strategic shift towards the usage of specialty silicones in aerospace and defense due to their durability and resistance to extreme environmental conditions. This shift is expected to open new avenues for market expansion.

- Sustainable Products: There is a growing emphasis on developing eco-friendly silicone products. Innovations in bio-based silicone production and recycling are pivotal in making the industry more sustainable. This trend not only responds to regulatory pressures but also aligns with the increasing consumer demand for environmentally friendly products.

- Construction Industry: The rising use of specialty silicones in the construction sector is a significant driver. Their application in sealants and adhesives, known for their durability and excellent weather resistance, supports the ongoing demand in this industry.

- Electric Vehicles (EVs): Specialty silicones are becoming integral in the manufacture of EVs, particularly for battery encapsulation and thermal management. This use is propelled by the need to improve battery efficiency and lifespan, marking a critical area of growth as the global automotive market shifts towards electric mobility.

- High-Performance Applications: The market is also benefiting from the demand for high-performance materials across various industries, including automotive and electronics. Specialty silicones are prized for their superior thermal stability and insulating properties, which are essential for applications in these sectors.

- Medical Sector Innovations: The healthcare sector continues to be a robust growth area for specialty silicones, especially with increasing uses in medical devices and implants where biocompatibility and performance are critical.

Key Player Analysis

AB Specialty Silicones, a prominent U.S. manufacturer and worldwide distributor, plays a significant role in the specialty silicone sector. They specialize in producing high-quality silicone chemicals for various industries, including personal care, chemical manufacturing, and electronics. Recently, AB Specialty Silicones expanded its influence by becoming an authorized distributor for Dow’s silicone polymers in the elastomeric roof coating market across the U.S. and Canada. This partnership aims to enhance the availability and application of high-performance, sustainable silicone solutions in North America.

The Bellofram Group of Companies, known for its engineering and manufacturing prowess, also engages significantly within the specialty silicone domain. They produce precision elastomers, including silicone products, that cater to demanding applications in sectors such as industrial manufacturing and automotive systems. Their focus on customized solutions that meet specific performance criteria underscores their commitment to quality and innovation in the silicone market.

Chemsil Silicones Inc. has carved out a niche in the specialty silicone sector, particularly serving the personal care and cosmetic industries. With over a decade of experience, Chemsil manufactures a wide range of high-quality silicone raw materials at their California facility. They are renowned for their ability to create custom silicone blends tailored to specific customer needs, enhancing product performance in applications ranging from hair care to skincare. Their expertise also extends to developing innovative silicone solutions that provide distinct market advantages to some of the largest personal care companies globally.

CHT Germany GmbH is another significant player in the specialty silicone market, primarily focusing on developing silicone formulations for various industrial applications. They offer a broad spectrum of silicone products, including those used in textiles, automotive, and electronics, emphasizing the versatility and performance enhancement that silicones bring to these sectors. CHT Germany’s commitment to quality and innovation is evident in their continuous efforts to improve product formulations to meet the evolving demands of their diverse clientele.

Dow is a leader in the specialty silicone market, leveraging its extensive material science expertise to innovate across various industries. The company focuses on creating silicone solutions that meet the evolving needs of technology, including the automotive and electronics sectors. Dow’s commitment to sustainability is evident in their development of carbon-neutral silicones for building facades and advanced materials for the 5G ecosystem, providing thermal management and EMI shielding solutions.

Elkay Chemicals Pvt Ltd is renowned in the specialty silicone sector for its focus on quality and customer-specific solutions. The company manufactures a wide range of silicone products, including fluids, emulsions, and compounds, catering to industries such as textiles, personal care, and pharmaceuticals. Elkay Chemicals is dedicated to delivering high-performance silicone products tailored to the unique requirements of each client, ensuring their position as a crucial supplier in the specialty silicone market.

Elkem ASA is a prominent player in the specialty silicone sector, consistently expanding its capabilities and reach. The company has recently committed to significant investments in its silicone production facilities to meet the increasing demand in the Americas and EMEA regions. This includes a major expansion of their plant in Roussillon, France, with a focus on enhancing productivity, cost-efficiency, and environmental performance. Elkem’s silicone products cater to a variety of high-tech and sustainable markets, including electric vehicles, healthcare, and 3D printing, positioning them as a leader in innovative silicone solutions.

Evonik Industries AG is also active in the specialty silicone market, particularly noted for their focus on creating high-quality silicone products that serve a broad range of applications. Their work includes developing silicones that enhance the performance of products across various industries, including automotive, healthcare, and electronics. Evonik’s commitment to technological advancement and sustainable practices helps them maintain a strong position in the global market, driving innovation in the silicone sector.

Innospec is an influential player in the specialty silicone sector, recognized for its comprehensive range of silicone-based products and solutions. This global specialty chemicals company caters to a variety of markets, including personal care, where it integrates Chemsil Silicones to strengthen its offerings. Innospec’s commitment to innovation is reflected in its wide array of performance chemicals that meet diverse industrial needs across the globe

K. K. Chempro India Pvt Ltd specializes in the distribution and marketing of silicone and specialty chemicals. They focus on providing customized solutions that meet the specific requirements of their clients, which spans across multiple industries including cosmetics, pharmaceuticals, textiles, and automotive. K. K. Chempro is known for its technical expertise and commitment to quality, ensuring that they deliver value-added services and products that enhance their clients’ operations and product offerings.

KCC Corporation has significantly bolstered its position in the global specialty silicone market through strategic acquisitions, notably acquiring the silicones business from Momentive Performance Materials. This move has expanded KCC’s capabilities in producing advanced silicones and specialty solutions, which are utilized in various sectors including electronics, healthcare, and construction. This strategic expansion aligns with KCC’s aim to enhance its product offerings and strengthen its market presence in the high-performance silicones sector globally

MESGO SpA specializes in the customization and production of high-performance silicone compounds, catering to a diverse range of industrial applications. The company is noted for its ability to develop innovative silicone solutions that meet specific customer needs, enhancing product performance across various sectors including automotive, aerospace, and healthcare. MESGO’s commitment to quality and innovation is central to its operations, positioning it as a key player in the European specialty silicone market.

Milliken & Company has established a robust presence in the specialty silicone market, leveraging its expertise in material science to enhance a wide range of consumer and industrial materials. They focus on producing specialty silanes, siloxanes, and silazanes that offer protective qualities and improve the performance of products by adding strength and increasing resistance to moisture, heat, and cold. Milliken’s approach to innovation in the silicone sector underscores their commitment to delivering high-quality, versatile solutions across various industries.

Momentive is a key player in the specialty silicone industry, known for its advanced silicone and specialty products tailored for demanding applications across diverse sectors such as healthcare, telecommunications, electronics, and construction. The company’s expertise in developing high-performance materials is complemented by its commitment to sustainability and innovation. This strategic focus enables Momentive to offer specialized solutions that significantly enhance product performance and meet the rigorous needs of their global clientele.

NuSil, under Avantor, is a leading formulator of high-purity silicone materials, renowned for its advanced silicone technology used in healthcare and space-grade applications. The company has been pivotal in producing adhesives, elastomers, and encapsulating materials that meet the stringent requirements of medical device manufacturers and aerospace applications. NuSil’s silicones are engineered for environments where ultimate purity and performance are critical, supporting innovations from medical implants to spacecraft components

Reiss Manufacturing Inc. is a specialist in the silicone and thermoplastic industry, recognized for its capability to produce custom-engineered compounds. Reiss offers a broad range of silicone products, including solid and sponge sheets, extruded profiles, and custom molded parts. The company is distinguished by its ability to deliver highly customized solutions that cater to specific industrial needs, emphasizing its strong expertise in both formulation and manufacturing processes to meet the diverse requirements of its clients.

Shin-Etsu Chemical Co. Ltd is a powerhouse in the specialty silicone sector, with a dominant presence particularly in Japan where it holds more than a 50% market share. Since its inception in 1953, Shin-Etsu has been at the forefront of silicone innovation, offering over 5,000 silicone products that serve a broad spectrum of industries including electronics, automotive, construction, cosmetics, and healthcare. The company’s commitment to high-quality and technologically advanced silicone solutions has made it a key player globally, continually expanding its product offerings and applications.

Siltech Corporation specializes in the development and manufacturing of silicone compounds, focusing on creating unique silicone polymers and custom formulations. Known for their innovation in silicone technology, Siltech offers a range of silicone products tailored to meet specific industry needs. Their products find applications across diverse sectors such as personal care, where they enhance the sensory properties and performance of beauty and health products, to industrial applications where their silicones improve product durability and functionality.

Specialty Silicone Products Inc. (SSP), now a subsidiary of HEICO Corporation, focuses on delivering high-performance silicone solutions tailored for demanding applications in markets like military, aerospace, and electronics. Founded in 1989 by former employees of GE Silicones, SSP specializes in the manufacture of EMI/RFI shielding silicones, custom molded and die-cut gaskets, and USP Class VI compliant silicones for medical devices. Their products are designed to meet rigorous specifications, including military and aerospace standards, making them a trusted partner for niche market solutions

Supreme Silicones excels in the specialty silicone sector by offering a wide range of silicone-based products that cater to various industrial needs. Their portfolio includes silicone emulsions, defoamers, and specialty additives used across different sectors like automotive, textile, and personal care. Known for their innovative approach, Supreme Silicones focuses on delivering tailored solutions that enhance the performance and efficiency of their clients’ products, ensuring quality and customer satisfaction through continuous product development and technical support.

The Lubrizol Corporation, a part of Berkshire Hathaway, is deeply involved in the specialty silicone market, focusing on creating sustainable and innovative solutions. Lubrizol’s products enhance a wide array of applications, from personal care to industrial uses, by improving performance and ensuring environmental sustainability. Their recent initiatives include developing eco-friendly alternatives to traditional silicones, which are pivotal in reducing environmental impact across various industries. This innovation aligns with global sustainability goals and meets increasing consumer demand for eco-conscious products

Wacker Chemie AG is a key player in the specialty silicone sector, known for its extensive range of silicone products that serve diverse industries, including electronics, automotive, and construction. The company is committed to technological advancement and sustainability, often leading the market with high-quality silicone solutions that are both effective and environmentally responsible. Wacker Chemie’s contributions to the silicone industry are marked by their continuous innovation and a strong focus on meeting the evolving needs of their global customers.

Conclusion

The Specialty Silicone market is poised for robust growth, driven by its expansive applications across multiple sectors such as aerospace, automotive, healthcare, electronics, and construction. With a projected compound annual growth rate of over 7%, the market is benefiting from the ongoing innovations and increasing demand for high-performance and sustainable materials. Key opportunities lie in developing eco-friendly products and enhancing applications in emerging technologies like electric vehicles and medical devices.

As industries continue to demand materials that offer superior performance and environmental sustainability, specialty silicones are set to play a crucial role in meeting these needs, ensuring their market prominence in the years to come. This growth trajectory underscores the material’s versatility and adaptability, cementing its status as a critical component in the advancement of various technological and industrial applications.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)