Table of Contents

Introduction

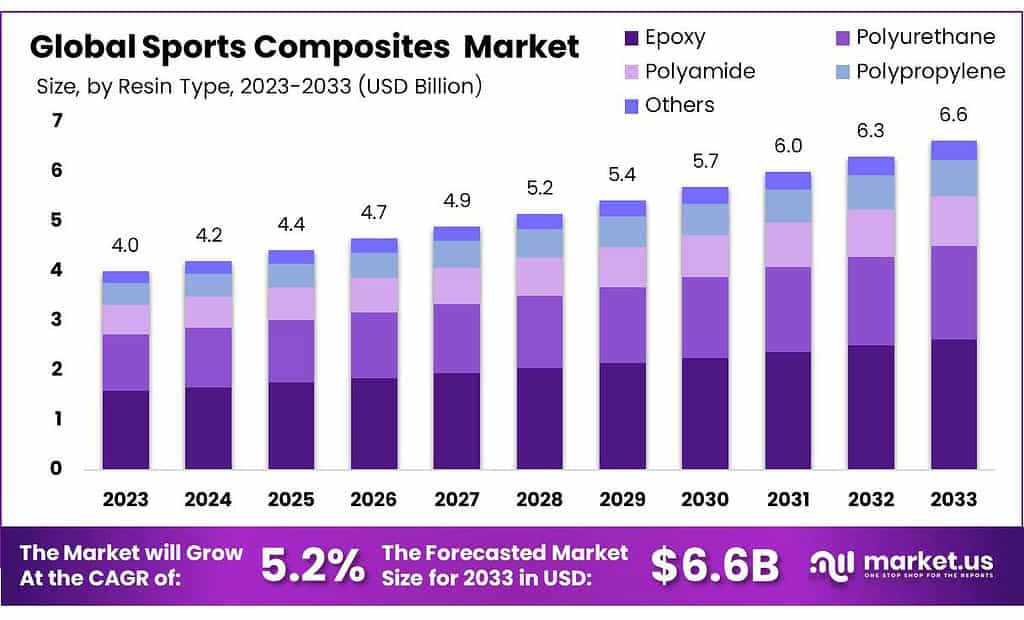

The global Sports Composites Market is projected to expand from USD 4.0 billion in 2023 to USD 6.6 billion by 2033, with a steady growth rate of 5.2% annually. This market’s growth is primarily driven by increasing global sports participation and the demand for high-performance, lightweight sports equipment which is crucial for professional and recreational activities alike.

Key growth factors include the rising popularity of sports tourism, with major events like the Olympics significantly influencing spending and engagement in sports activities. Additionally, advancements in materials science, such as the development of new composite materials including carbon fiber, which is favored for its strength-to-weight ratio, are propelling the market forward. The carbon fiber segment, in particular, dominates the market due to its extensive application in manufacturing durable and lightweight sports gear such as bicycles, golf clubs, and racquets.

However, the market faces challenges such as the environmental impact of composite materials, which are often difficult to recycle, thus posing disposal problems. This has led to heightened regulatory scrutiny and could potentially increase manufacturing costs as the industry seeks more sustainable alternatives.

Recent developments highlight the sector’s innovation focus, with companies like SGL Carbon and TEIJIN LIMITED launching new, high-performance materials tailored for sports applications. This innovation extends to the use of eco-friendly materials, like recycled carbon fibers and bio-composites, catering to growing consumer demand for sustainable products.

ALDILA, Inc. has been focusing on advancing its technology and expanding its product line to cater to the growing demand for high-quality sports composites. The company specializes in producing composite materials that are crucial for the manufacture of sports equipment, particularly in golf.

Amer Sports continues to leverage its research and development capabilities to innovate high-performance materials for sports applications. Recent activities suggest a strategic push to capture a larger market share in the sports composites sector through the development of advanced materials that meet the specific needs of competitive sports and active lifestyle products.

Callaway Golf has been proactive in integrating new technologies into its products, with a strong focus on golf clubs and balls that utilize advanced composite materials. This includes the adoption of new manufacturing processes that enhance the performance characteristics of golf equipment, making them lighter and more durable.

Sports Composites Statistics

- Test results showed that high-performance composite sports equipment could improve the quality of sports equipment by 25% and had greatly improved sports brand promotion, sports brand positioning, and sports brand sponsorship.

- To explore what kind of quality changes high-performance composite materials can bring to sports equipment, a questionnaire survey was conducted among 80 sports equipment manufacturers.

- The experiment selected 20 sports brands of comparable size, half of which used high-performance composite sports equipment and the other half used traditional sports equipment.

- The conventional equipment showed steady change over the six months, with an average ductility, wear resistance, and corrosion resistance of 8.8%, 57%, and 56%, respectively.

- Over time, the quality of sports equipment continued to increase, and the data on the quality of three materials were 28%, 79%, and 87.3%.

- The average level of branding for high-performance composite sports equipment was 58%, and the average level of branding for traditional sports equipment was 24%.

Emerging Trends

- Advanced Recycling Techniques: The development of innovative recycling methods for composite materials is a major trend. As environmental regulations tighten, especially regarding landfill use, the sports composites industry is exploring efficient mechanical, thermal, and chemical recycling processes for materials like carbon and glass fiber-reinforced composites.

- Customization through 3D Printing: There’s a growing trend towards using 3D printing to manufacture sports composites. This technology allows for the creation of complex shapes and customized sports equipment at lower costs and shorter production times. Start-ups are particularly active in this space, developing new material sciences applications to enhance the production and performance characteristics of carbon fiber composites.

- Sustainability and Eco-friendly Materials: The sports composites market is increasingly incorporating sustainable practices. This includes the use of recycled and bio-based materials which are gaining popularity due to their reduced environmental impact. The market is responding to a heightened consumer and regulatory demand for greener products.

- Growth in High-Performance Sports: As global participation in high-performance sports like golf, cycling, and skiing increases, there is a corresponding rise in demand for sports composites that offer superior strength-to-weight ratios and durability. This trend is supported by advancements in materials like carbon fiber that meet these performance demands while also allowing for greater design flexibility.

Use Cases

- Golf Equipment: Composites are extensively utilized in golf clubs, especially in shafts and club heads. For instance, carbon fiber is preferred due to its superior strength-to-weight ratio, allowing for clubs that are both lightweight and strong. This has led to better swing speeds and improved performance, with some high-end golf clubs now incorporating up to 50% composite materials.

- Cycling: In the cycling industry, composite materials are crucial for making lightweight frames and components. Many professional bicycles now feature carbon fiber frames, which can reduce weight by 30% compared to traditional aluminum or steel frames. This is particularly beneficial for competitive cyclists looking to enhance speed and agility.

- Hockey Sticks: Hockey sticks have evolved significantly, with many high-performance models constructed from composite materials. The integration of carbon fiber and fiberglass in sticks allows for better energy transfer during shots, resulting in faster puck speeds. Reports indicate that the use of composites can enhance shot power by as much as 20% compared to wooden sticks.

- Skis and Snowboards: Composites are also employed in skiing and snowboarding equipment. The combination of materials such as fiberglass and carbon fiber helps manufacturers create skis and boards that are both lightweight and resilient, improving maneuverability and performance on the slopes. Many top brands now use composites extensively, leading to enhanced durability and reduced fatigue for athletes.

- Protective Gear: In sports like football and lacrosse, composites are used in protective gear such as helmets and pads. The lightweight nature of these materials, combined with their ability to absorb impact, significantly enhances player safety without compromising mobility. Innovations in composite technology have led to gear that meets stringent safety standards while being lighter than traditional materials.

Major Challenges

- High Production Costs: The manufacturing of composite materials, particularly carbon fiber, involves complex processes that can be costly. Production costs for high-quality carbon fiber can range from $20 to $30 per kilogram, making it more expensive than traditional materials like aluminum or fiberglass. This can limit the affordability of composite sports equipment for consumers.

- Limited Recycling Options: Composite materials are known for their durability, but this also poses a challenge regarding end-of-life disposal. Traditional recycling methods for composites are still developing, and the majority end up in landfills. Recent estimates suggest that less than 5% of composite materials are currently recycled effectively, raising environmental concerns and regulatory pressures.

- Market Awareness: There is a general lack of awareness among consumers regarding the advantages of using sports composites. Many athletes and recreational users are not fully informed about the performance benefits and long-term durability of composite materials compared to traditional options. This knowledge gap can hinder market growth.

- Regulatory Challenges: Stringent regulations surrounding the use and disposal of composite materials can create barriers to market entry. These regulations may impose additional compliance costs on manufacturers, potentially stifling innovation and increasing the price of end products.

- Competition from Traditional Materials: While composites offer many advantages, they face stiff competition from established materials such as aluminum and wood. In certain applications, especially in recreational sports, consumers may prefer the familiarity and lower cost of traditional materials, limiting the market penetration of composites.

Market Growth Opportunities

- Rising Demand for High-Performance Equipment: As more athletes seek competitive advantages, the demand for lightweight and durable sports equipment made from composite materials is expected to increase. The market for sports composites is projected to grow significantly, with estimates suggesting a compound annual growth rate (CAGR) of approximately 5.2%, reaching around USD 6.6 billion by 2033.

- Advancements in Material Technology: Continuous innovations in composite manufacturing processes, such as improvements in 3D printing and advanced recycling techniques, create opportunities for more efficient production. These technologies can lower costs and improve product performance, making composites more accessible to a broader range of consumers.

- Expansion in Emerging Markets: The growing popularity of sports and recreational activities in regions such as Asia-Pacific and Latin America provides significant growth potential. Countries like China and India are witnessing increased participation in various sports, driving the demand for advanced sports equipment made from composites.

- Sustainability Initiatives: There is an increasing consumer focus on sustainability, prompting manufacturers to develop eco-friendly composite materials. The use of recycled fibers and bio-based resins can cater to environmentally conscious consumers and help companies meet regulatory demands, creating a unique selling proposition in the market.

- Increased Investment in Sports Infrastructure: Government and private investments in sports infrastructure, such as the construction of new sports facilities and events, are likely to drive demand for sports equipment. The rise of professional leagues and tournaments worldwide enhances the need for high-quality, durable sports equipment, further boosting the sports composites market.

Key Player Analysis

ALDILA, Inc. is a key player in the sports composites sector, primarily recognized for its innovative golf shafts made from advanced composite materials. The company leverages cutting-edge carbon fiber technology to produce lightweight, high-performance shafts that enhance golfers’ swing speed and control. With a commitment to continuous research and development, ALDILA focuses on improving product performance, positioning itself as a leader in the golf equipment market. Its products are widely used by professional and amateur golfers alike, contributing significantly to the growth of the sports composites industry.

Amer Sports operates as a major entity in the sports composites market, focusing on enhancing athletic performance through advanced materials and technologies. The company develops high-quality sporting goods, including equipment for winter sports, cycling, and outdoor activities, utilizing composite materials for their strength and durability. By investing in research and development, Amer Sports aims to innovate and expand its product lines, addressing the evolving needs of athletes. Their commitment to performance-driven designs ensures a competitive edge in the rapidly growing sports composites sector.

Callaway Golf is a prominent player in the sports composites sector, renowned for its innovative use of composite materials in golf equipment. The company designs high-performance golf clubs and balls, utilizing advanced materials like carbon fiber to enhance strength and reduce weight. This focus on technology allows Callaway to deliver products that improve golfers’ performance, from swing speed to accuracy. Their commitment to continuous innovation and product development helps maintain their competitive edge in the rapidly evolving golf market.

Celanese Corporation plays a significant role in the sports composites sector by providing advanced polymer materials that enhance the performance and durability of sports equipment. The company focuses on developing high-quality composite materials suitable for various applications, including sporting goods. By leveraging their expertise in material science, Celanese aims to create innovative solutions that meet the demands of athletes and manufacturers alike. Their commitment to sustainability and performance makes them a vital contributor to the growth of the sports composites market.

Dexcraft is an emerging player in the sports composites sector, specializing in advanced composite solutions for various athletic applications. The company focuses on producing high-performance materials that are lightweight and durable, making them ideal for sports equipment such as bicycles, skateboards, and protective gear. By utilizing innovative manufacturing techniques, Dexcraft aims to enhance product performance while meeting the growing demands of athletes and manufacturers. Their commitment to quality and technological advancement positions them as a competitive force in the sports composites market.

EPSILON Composite is a key contributor to the sports composites industry, providing cutting-edge composite materials designed for high-performance sporting goods. The company specializes in lightweight and robust materials suitable for various applications, including cycling, skiing, and other outdoor sports equipment. By leveraging advanced engineering and material science, EPSILON aims to improve the durability and performance of sports gear. Their focus on innovation and quality ensures that they meet the needs of both professional athletes and recreational users, driving growth within the sports composites sector.

Exel Composites is a prominent player in the sports composites sector, focusing on the design and manufacture of high-quality composite solutions for various sports applications. The company specializes in producing lightweight and durable components, particularly for archery, cycling, and other outdoor sports equipment. By leveraging advanced composite technology, Exel Composites enhances product performance and user experience. Their commitment to innovation and sustainability positions them well in a competitive market, catering to the growing demands of athletes and manufacturers for high-performance sporting goods.

Fischer Sports GmbH is a leading manufacturer in the sports composites market, renowned for its innovative ski and outdoor equipment. The company employs advanced composite materials in the production of skis, snowboards, and poles, focusing on lightweight and high-performance designs that enhance user experience. Fischer integrates technology and material science to create durable products that meet the demands of both competitive athletes and recreational users. Their dedication to quality and performance ensures a strong position in the evolving landscape of sports composites.

Exel Composites is a significant player in the sports composites sector, specializing in the development of high-performance composite materials for a variety of applications. The company focuses on producing lightweight and durable components, particularly for sports like archery, cycling, and fishing. By utilizing advanced composite technologies, Exel Composites enhances product functionality and athlete performance. Their commitment to innovation and quality ensures that they meet the growing demands of the sports market, solidifying their reputation as a leader in composite manufacturing.

Fischer Sports GmbH is a prominent manufacturer in the sports composites market, known for its cutting-edge ski and outdoor equipment. The company utilizes advanced composite materials to produce skis, snowboards, and poles, emphasizing lightweight designs that improve performance and user comfort. Fischer’s innovative approach combines technology with material science to create durable, high-quality products suitable for both professional athletes and recreational users. Their focus on performance and sustainability positions Fischer as a key player in the competitive sports composites landscape.

Hexcel Corporation is a leading player in the sports composites sector, specializing in advanced composite materials used in high-performance sporting goods. The company produces carbon fiber, honeycomb structures, and resin systems that enhance the strength and lightweight characteristics of equipment such as bicycles, skis, and tennis rackets. Hexcel’s focus on innovation and sustainability allows it to meet the evolving demands of athletes and manufacturers, solidifying their position as a key supplier in the competitive sports composites market.

Mitsubishi Chemical Carbon Fiber and Composites Inc. plays a crucial role in the sports composites sector by providing high-quality carbon fiber and composite materials. The company focuses on developing lightweight, strong materials that improve the performance and durability of sports equipment, including cycling gear, fishing rods, and outdoor sporting goods. By leveraging advanced technology and research, Mitsubishi aims to create innovative solutions that cater to the needs of athletes, helping to enhance their performance while promoting sustainability in the sports industry.

Newell Brands is a notable player in the sports composites sector, focusing on producing a range of outdoor and sports products that incorporate advanced composite materials. The company’s portfolio includes well-known brands that utilize lightweight and durable composites to enhance performance in products such as fishing rods, camping gear, and athletic equipment. By leveraging innovative materials, Newell Brands aims to meet consumer demands for high-quality and performance-driven products, solidifying its position in the competitive sports market.

ProKennex is recognized for its specialized work in the sports composites sector, particularly in the production of tennis and squash equipment. The company emphasizes the use of advanced composite technologies to create lightweight and durable rackets that enhance player performance. ProKennex is known for its innovative designs that incorporate shock-absorbing features, promoting comfort and reducing the risk of injury. By focusing on quality and performance, ProKennex aims to cater to both amateur and professional athletes, reinforcing its position in the competitive sports composites landscape.

Rossignol and Fischer Sports are leading companies in the sports composites sector, particularly known for their innovative ski and snowboard equipment. Both brands utilize advanced composite materials to produce lightweight and high-performance skis, poles, and snowboards. By focusing on materials that enhance durability and agility, Rossignol and Fischer aim to improve the overall performance and experience of winter sports enthusiasts. Their commitment to research and development ensures they remain competitive, catering to both professional athletes and recreational users in the dynamic sports market.

SGL Carbon is a prominent player in the sports composites sector, specializing in high-performance carbon fiber materials. The company produces lightweight and strong composites that are used in various sports equipment, including cycling gear, tennis rackets, and skiing equipment. By leveraging advanced manufacturing technologies, SGL Carbon focuses on enhancing product performance and durability, addressing the specific needs of athletes. Their commitment to innovation and quality positions them as a key supplier in the sports composites industry, supporting the growth of high-performance sporting goods.

TEIJIN LIMITED is a significant player in the sports composites sector, focusing on the development of advanced materials, including aramid and carbon fibers. The company is known for its innovative composite solutions that enhance the performance and durability of sports equipment, such as bicycles, athletic gear, and outdoor products. By leveraging its expertise in material science, TEIJIN aims to meet the evolving needs of athletes and manufacturers, positioning itself as a leader in high-performance composite materials within the competitive sports market.

Topkey specializes in providing advanced composite materials tailored for various sports applications. The company focuses on creating lightweight, durable products for sporting goods, including fishing rods, bicycle frames, and outdoor gear. By utilizing innovative manufacturing techniques, Topkey enhances the performance and reliability of its products, appealing to both amateur and professional athletes. Their commitment to quality and technological advancement positions Topkey as a noteworthy contributor in the growing sports composites sector, catering to the increasing demand for high-performance sporting equipment.

Toray Composite Materials America, Inc. is a key player in the sports composites sector, specializing in advanced composite materials such as carbon fiber and epoxy resins. The company focuses on producing lightweight and high-strength materials used in various sports equipment, including bicycles, golf clubs, and protective gear. By leveraging innovative manufacturing processes, Toray aims to enhance the performance and durability of sporting goods, catering to both professional athletes and recreational users. Their commitment to research and development positions them as a leader in the competitive sports composites market.

True Temper is a well-known manufacturer in the sports composites sector, particularly recognized for its high-performance golf shafts and other sporting equipment. The company utilizes advanced composite materials to create lightweight, strong, and flexible shafts that enhance player performance. True Temper focuses on innovation, employing cutting-edge technology to improve the design and functionality of its products. By addressing the specific needs of athletes, True Temper reinforces its position as a top choice among golfers and contributes significantly to the growth of the sports composites industry.

Conclusion

In conclusion, the sports composites market is poised for substantial growth driven by advancements in material technology, increasing consumer demand for high-performance equipment, and a growing emphasis on sustainability. With projections indicating a market size of approximately USD 6.6 billion by 2033, opportunities abound in emerging markets and through innovations such as 3D printing and eco-friendly materials.

However, challenges such as high production costs and limited recycling options must be addressed to fully realize this potential. Companies that navigate these dynamics effectively will likely position themselves at the forefront of a rapidly evolving industry, catering to the needs of both professional and recreational athletes. Overall, the outlook for sports composites remains promising, offering a pathway for innovation and enhanced performance in various sports applications.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)